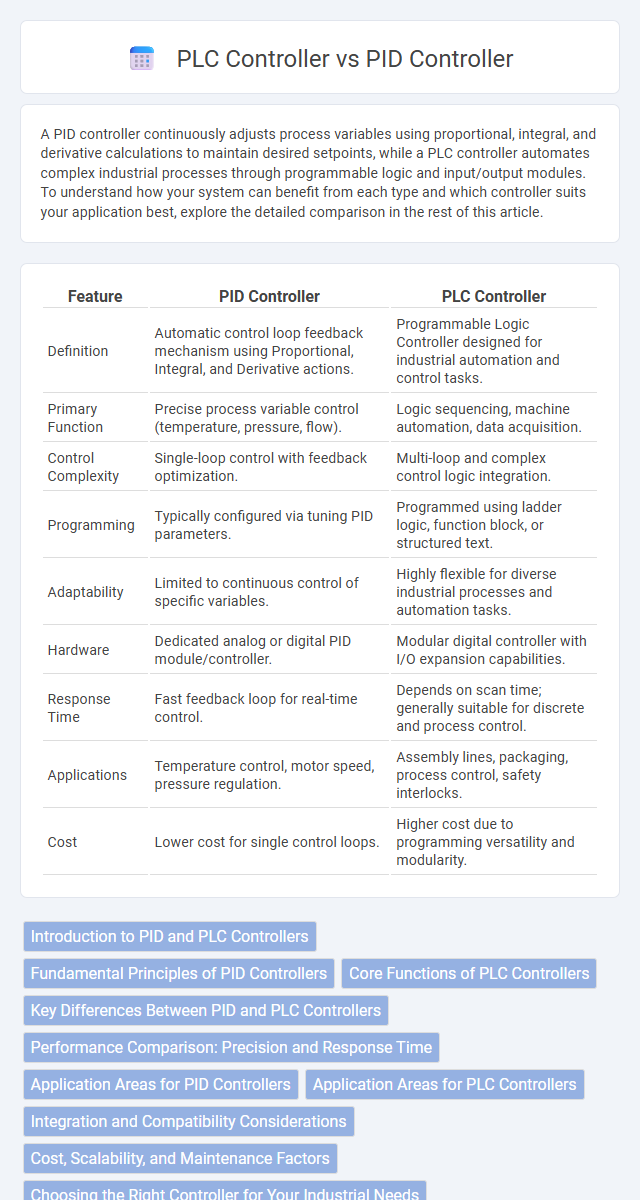

A PID controller continuously adjusts process variables using proportional, integral, and derivative calculations to maintain desired setpoints, while a PLC controller automates complex industrial processes through programmable logic and input/output modules. To understand how your system can benefit from each type and which controller suits your application best, explore the detailed comparison in the rest of this article.

Table of Comparison

| Feature | PID Controller | PLC Controller |

|---|---|---|

| Definition | Automatic control loop feedback mechanism using Proportional, Integral, and Derivative actions. | Programmable Logic Controller designed for industrial automation and control tasks. |

| Primary Function | Precise process variable control (temperature, pressure, flow). | Logic sequencing, machine automation, data acquisition. |

| Control Complexity | Single-loop control with feedback optimization. | Multi-loop and complex control logic integration. |

| Programming | Typically configured via tuning PID parameters. | Programmed using ladder logic, function block, or structured text. |

| Adaptability | Limited to continuous control of specific variables. | Highly flexible for diverse industrial processes and automation tasks. |

| Hardware | Dedicated analog or digital PID module/controller. | Modular digital controller with I/O expansion capabilities. |

| Response Time | Fast feedback loop for real-time control. | Depends on scan time; generally suitable for discrete and process control. |

| Applications | Temperature control, motor speed, pressure regulation. | Assembly lines, packaging, process control, safety interlocks. |

| Cost | Lower cost for single control loops. | Higher cost due to programming versatility and modularity. |

Introduction to PID and PLC Controllers

PID controllers use proportional, integral, and derivative algorithms to maintain precise control over processes by continuously adjusting output based on error values. PLC controllers offer programmable logic control for automation tasks, enabling complex sequencing, monitoring, and decision-making in industrial environments. Your choice depends on whether you need continuous process control (PID) or flexible automation and control logic (PLC).

Fundamental Principles of PID Controllers

PID controllers rely on proportional, integral, and derivative actions to continuously calculate an error value between a desired setpoint and a measured process variable. Their fundamental principle focuses on minimizing this error by adjusting control inputs to achieve stable, precise system behavior. You benefit from rapid response and fine-tuned control in processes requiring constant adjustment, unlike PLC controllers that primarily execute logic-based automation tasks.

Core Functions of PLC Controllers

PLC controllers primarily manage discrete control tasks using ladder logic programming to automate complex industrial processes by monitoring inputs and controlling outputs. They excel in sequential control, real-time decision making, and handling multiple control loops simultaneously, unlike PID controllers which focus on continuous process control. PLCs integrate with sensors, actuators, and network protocols to provide comprehensive system management and diagnostics in manufacturing environments.

Key Differences Between PID and PLC Controllers

PID controllers use proportional, integral, and derivative algorithms to regulate process variables with precision and continuous control. PLC controllers are programmable logic devices designed to perform discrete control tasks through logic-based programming and can manage complex automation systems beyond simple feedback loops. Understanding these key differences helps you choose between precise analog control (PID) and versatile digital automation (PLC) for your industrial applications.

Performance Comparison: Precision and Response Time

PID controllers excel in precision and rapid response time by continuously adjusting control variables based on process error, making them ideal for fine-tuned temperature or pressure regulation. PLC controllers offer broader system control capabilities but typically exhibit slower response times due to their scan cycle operations, which may affect precision in highly dynamic processes. Your choice depends on the need for precise, swift control versus more complex automation and flexibility.

Application Areas for PID Controllers

PID controllers excel in precise temperature regulation, flow control, and pressure maintenance within industries like chemical processing, HVAC systems, and water treatment plants. They provide continuous, automatic adjustments to maintain system stability in processes requiring real-time correction of variables such as speed, position, and torque. Your automation projects benefit from PID controllers' ability to deliver smooth and accurate control in dynamic environments where feedback loops are critical.

Application Areas for PLC Controllers

PLC controllers excel in diverse industrial automation applications such as manufacturing assembly lines, robotic device coordination, and process control systems. Their programmable logic allows for flexible customization in sectors including automotive, pharmaceuticals, food processing, and material handling. Your facility benefits from PLC controllers by achieving precise control, real-time monitoring, and integration with SCADA systems for optimized operational efficiency.

Integration and Compatibility Considerations

PID controllers excel in precise process control through continuous feedback loop adjustments, making them highly compatible with analog sensor inputs and industrial control systems. PLC controllers offer broader integration capabilities, supporting diverse I/O modules, communication protocols, and complex logic functions, which allows seamless integration with existing automation networks and SCADA systems. When choosing between the two, consider your system's compatibility requirements and how your control infrastructure will incorporate real-time data management and advanced automation tasks.

Cost, Scalability, and Maintenance Factors

PID controllers offer lower initial costs and are ideal for specific, continuous process control tasks, while PLC controllers involve higher upfront investment but provide superior scalability for complex automation systems. Maintenance of PID controllers is generally simpler and less frequent due to their focused functionality, whereas PLCs require more extensive upkeep to manage diverse modules and software updates. Choosing between PID and PLC controllers depends on budget constraints, the complexity of automation needs, and long-term maintenance capabilities.

Choosing the Right Controller for Your Industrial Needs

Selecting the right controller for your industrial application depends on the complexity and precision required; PID controllers excel in continuous process control by maintaining setpoint stability through proportional, integral, and derivative functions. PLC controllers offer versatile automation with programmable logic, making them ideal for sequential operations, complex machinery, or systems requiring extensive input/output interfacing. Assessing your process dynamics and control objectives helps determine whether the rapid, analog response of a PID or the flexible, digital logic of a PLC best meets your operational demands.

PID Controller vs PLC Controller Infographic

electrown.com

electrown.com