Analog output modules provide variable voltage or current signals representing continuous data, ideal for precise control in industrial automation. Digital output modules, by contrast, switch between fixed on/off states to control devices like relays or indicators; explore the rest of the article to understand which module best suits your application.

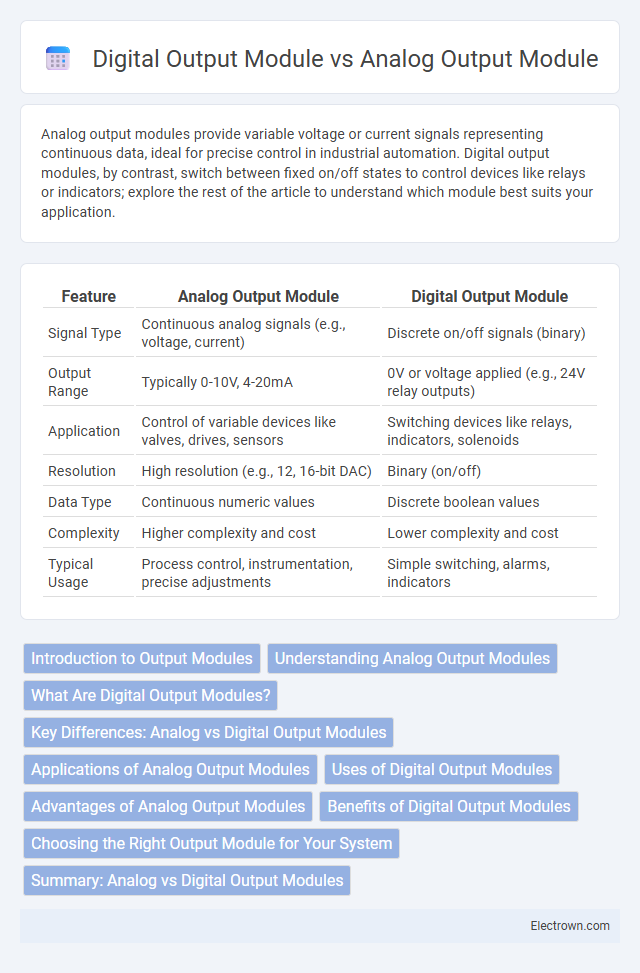

Table of Comparison

| Feature | Analog Output Module | Digital Output Module |

|---|---|---|

| Signal Type | Continuous analog signals (e.g., voltage, current) | Discrete on/off signals (binary) |

| Output Range | Typically 0-10V, 4-20mA | 0V or voltage applied (e.g., 24V relay outputs) |

| Application | Control of variable devices like valves, drives, sensors | Switching devices like relays, indicators, solenoids |

| Resolution | High resolution (e.g., 12, 16-bit DAC) | Binary (on/off) |

| Data Type | Continuous numeric values | Discrete boolean values |

| Complexity | Higher complexity and cost | Lower complexity and cost |

| Typical Usage | Process control, instrumentation, precise adjustments | Simple switching, alarms, indicators |

Introduction to Output Modules

Output modules serve as critical interfaces in industrial automation, converting signals from a controller into usable outputs for machinery and devices. Analog output modules transmit variable signals, typically voltage or current, allowing precise control of actuators such as valves and motors, while digital output modules send discrete on/off signals to devices like relays, solenoids, and indicator lights. Selection between analog and digital output modules depends on application requirements, with analog modules offering fine-tuned control and digital modules providing simple switching commands.

Understanding Analog Output Modules

Analog Output Modules convert digital signals from a controller into continuous voltage or current signals for precise control of devices like actuators and valves. They enable smooth adjustments by producing varying output levels rather than simple ON/OFF states, making them essential for processes requiring fine control. Your system's performance improves significantly when the appropriate analog output module is selected to match the required signal range and resolution.

What Are Digital Output Modules?

Digital output modules are industrial automation components designed to control and switch discrete devices by sending binary signals, representing on/off states. These modules convert electrical signals from a control system into digital outputs that operate devices like relays, solenoids, and indicator lights. Compared to analog output modules that handle continuous signals, digital output modules provide precise, reliable switching for automation processes requiring clear, distinct status changes.

Key Differences: Analog vs Digital Output Modules

Analog output modules deliver continuously variable voltage or current signals, allowing precise control of devices such as valves and speed drives. Digital output modules provide discrete on/off signals, suitable for controlling relays, indicators, and solenoids. Understanding these key differences helps you select the appropriate module for accurate process control or simple switching tasks.

Applications of Analog Output Modules

Analog output modules are extensively used in industrial automation for precise control of process variables such as temperature, pressure, and flow by converting digital signals into continuous analog voltages or currents. These modules are essential in applications requiring smooth operation of actuators, valves, and variable speed drives, enabling fine-tuned adjustments and feedback control in manufacturing systems. Industries like chemical processing, HVAC systems, and robotics rely on analog output modules to ensure accurate and stable performance of control systems.

Uses of Digital Output Modules

Digital output modules are primarily used to control devices that operate on binary signals, such as turning lights, relays, and motors on or off in industrial automation systems. These modules convert digital control signals from a PLC or controller into electrical outputs that enable precise switching of connected equipment. Your automation setup benefits from digital output modules by enhancing discrete control and improving system responsiveness for tasks requiring simple on/off operations.

Advantages of Analog Output Modules

Analog output modules provide precise control over devices by delivering continuously variable signals, allowing for fine adjustments in applications such as temperature regulation or motor speed control. These modules support a wide range of values, enabling smooth and accurate operation compared to the binary on/off signals of digital output modules. Your system benefits from enhanced flexibility and improved performance in processes requiring proportional output.

Benefits of Digital Output Modules

Digital output modules provide precise and reliable control of devices by offering discrete ON/OFF signals, ensuring faster response times and simpler wiring compared to analog output modules. They enable efficient automation in industrial systems by minimizing signal interference and enhancing compatibility with a wide range of digital equipment. Reduced maintenance costs and improved system diagnostics are achieved due to their straightforward design and robust performance in harsh environments.

Choosing the Right Output Module for Your System

Choosing the right output module depends on the specific requirements of your control system, where an analog output module delivers variable voltage or current signals ideal for precise control of devices like actuators and sensors, while a digital output module sends discrete ON/OFF signals suitable for switching relays, indicators, or alarms. Consider the type of device being controlled, required signal resolution, and system complexity to ensure compatibility and efficiency. Selecting the appropriate module enhances system performance, reduces errors, and supports accurate real-time control operations.

Summary: Analog vs Digital Output Modules

Analog output modules provide continuous signals that vary within a range, enabling precise control of devices like valves and actuators. Digital output modules deliver discrete on/off signals suitable for controlling relays, lights, or motors. Your choice depends on whether you require variable control (analog) or simple switching (digital) for your automation system.

Analog Output Module vs Digital Output Module Infographic

electrown.com

electrown.com