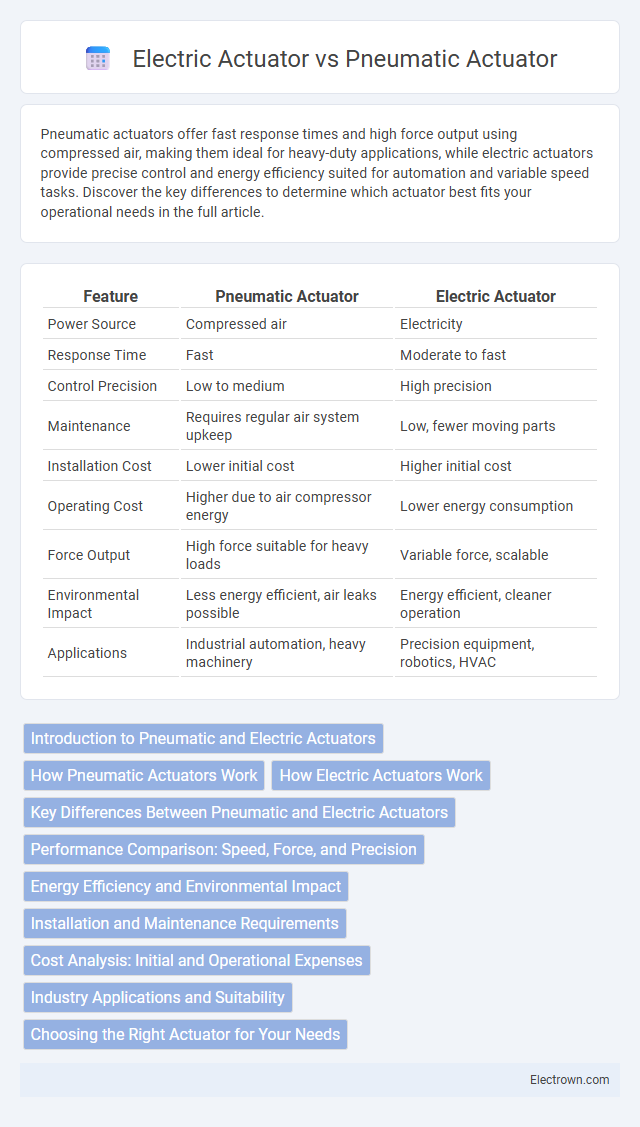

Pneumatic actuators offer fast response times and high force output using compressed air, making them ideal for heavy-duty applications, while electric actuators provide precise control and energy efficiency suited for automation and variable speed tasks. Discover the key differences to determine which actuator best fits your operational needs in the full article.

Table of Comparison

| Feature | Pneumatic Actuator | Electric Actuator |

|---|---|---|

| Power Source | Compressed air | Electricity |

| Response Time | Fast | Moderate to fast |

| Control Precision | Low to medium | High precision |

| Maintenance | Requires regular air system upkeep | Low, fewer moving parts |

| Installation Cost | Lower initial cost | Higher initial cost |

| Operating Cost | Higher due to air compressor energy | Lower energy consumption |

| Force Output | High force suitable for heavy loads | Variable force, scalable |

| Environmental Impact | Less energy efficient, air leaks possible | Energy efficient, cleaner operation |

| Applications | Industrial automation, heavy machinery | Precision equipment, robotics, HVAC |

Introduction to Pneumatic and Electric Actuators

Pneumatic actuators utilize compressed air to generate mechanical motion, offering rapid response times and high force output suitable for industrial automation and valve control applications. Electric actuators rely on electric motors for precise positioning and control, delivering energy efficiency and ease of integration with digital control systems in manufacturing and robotics. Both actuator types serve essential roles in motion control, with pneumatic actuators favored for simplicity and durability, while electric actuators excel in accuracy and programmable operation.

How Pneumatic Actuators Work

Pneumatic actuators operate by converting compressed air into mechanical motion, typically through a piston or diaphragm that moves within a cylinder to create linear or rotary movement. These actuators are known for their rapid response times and high force-to-weight ratios, making them ideal for applications requiring quick, repetitive motion. Your system benefits from their simplicity and reliability, especially in environments where explosive or hazardous conditions make electric actuators less suitable.

How Electric Actuators Work

Electric actuators operate by converting electrical energy into mechanical motion through a motor-driven system, allowing precise control of valve positioning or movement. These actuators use internal components such as gears, encoders, and control circuits to regulate torque and speed, providing accurate and repeatable performance for various industrial applications. Your choice of electric actuator ensures energy-efficient operation and easy integration with automated control systems.

Key Differences Between Pneumatic and Electric Actuators

Pneumatic actuators operate using compressed air to create mechanical motion, offering rapid response times and high force output ideal for heavy-duty applications. Electric actuators convert electrical energy into mechanical motion, providing precise control, energy efficiency, and easier integration with automated systems. Key differences include energy source, control precision, maintenance requirements, and operating environments, with pneumatic actuators excelling in explosive or hazardous zones and electric actuators favored for clean, precise positioning tasks.

Performance Comparison: Speed, Force, and Precision

Pneumatic actuators excel in delivering high force and rapid response times, making them ideal for applications requiring quick, powerful movements, but they typically lack the precision control found in electric actuators. Electric actuators provide superior precision and controllability through fine adjustment capabilities and integrated feedback systems, albeit with generally slower speed and lower force compared to pneumatic systems. The choice between pneumatic and electric actuators depends on balancing the requirements for speed, force, and precision based on specific industrial or automation needs.

Energy Efficiency and Environmental Impact

Pneumatic actuators rely on compressed air, which often results in energy losses due to air leaks and inefficiencies in compressors, making them less energy-efficient compared to electric actuators. Electric actuators provide precise control and consume energy directly from electrical sources, leading to higher overall energy efficiency and reduced operational costs. Environmentally, electric actuators produce fewer emissions and can be powered by renewable energy, whereas pneumatic systems depend heavily on energy-intensive air compression, increasing their carbon footprint.

Installation and Maintenance Requirements

Pneumatic actuators require compressed air systems and precise piping for installation, often demanding regular inspection of air supply quality to prevent corrosion or wear. Electric actuators involve complex wiring and electronic controls, which necessitate skilled technicians for installation and periodic software updates along with mechanical checks. Maintenance for pneumatic systems focuses on air filter replacements and seal inspections, while electric actuators require routine calibration and monitoring of motor performance to ensure reliable operation.

Cost Analysis: Initial and Operational Expenses

Pneumatic actuators typically have lower initial costs due to simpler design and cheaper materials but incur higher operational expenses because of compressed air system maintenance and energy consumption. Electric actuators, while more expensive upfront due to motors and control electronics, offer lower long-term operational costs with higher energy efficiency and less frequent maintenance. Your choice should weigh initial investment against ongoing costs for optimal budget planning.

Industry Applications and Suitability

Pneumatic actuators are widely used in industries such as oil and gas, manufacturing, and food processing due to their rapid response, high force output, and suitability for hazardous environments. Electric actuators excel in applications requiring precise control, energy efficiency, and integration with automated systems, commonly found in HVAC, robotics, and semiconductor manufacturing. Selection depends on factors like environmental conditions, speed, torque requirements, and maintenance preferences, with pneumatic systems favored for explosive atmospheres and electric actuators preferred for clean, controlled settings.

Choosing the Right Actuator for Your Needs

Choosing the right actuator depends on factors such as speed, precision, and power source availability. Pneumatic actuators offer fast response times and high force but require compressed air systems and may lack precise positioning. Electric actuators provide accurate control, easy integration with digital systems, and lower maintenance, making them ideal for applications requiring fine-tuned motion and energy efficiency.

Pneumatic Actuator vs Electric Actuator Infographic

electrown.com

electrown.com