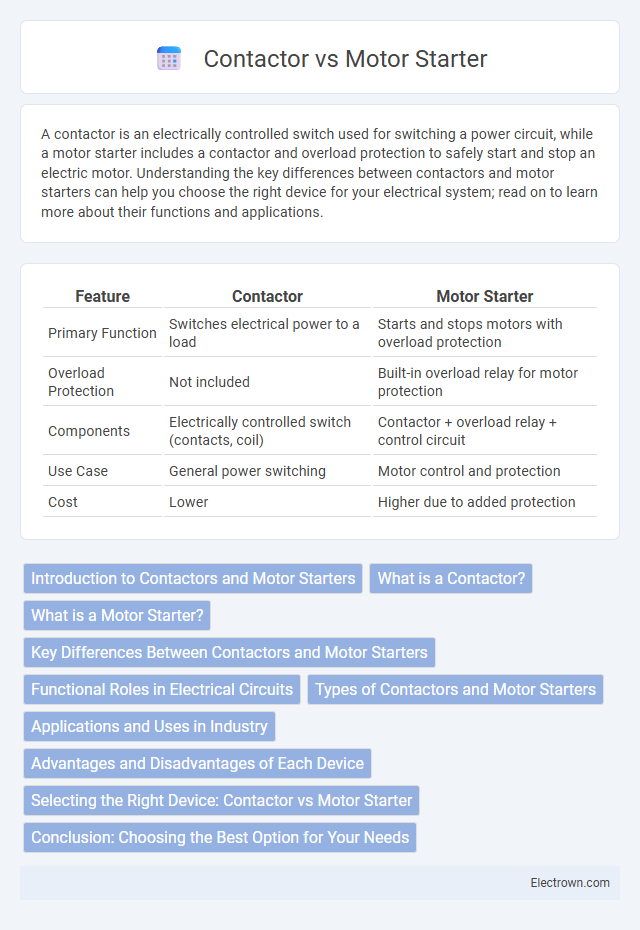

A contactor is an electrically controlled switch used for switching a power circuit, while a motor starter includes a contactor and overload protection to safely start and stop an electric motor. Understanding the key differences between contactors and motor starters can help you choose the right device for your electrical system; read on to learn more about their functions and applications.

Table of Comparison

| Feature | Contactor | Motor Starter |

|---|---|---|

| Primary Function | Switches electrical power to a load | Starts and stops motors with overload protection |

| Overload Protection | Not included | Built-in overload relay for motor protection |

| Components | Electrically controlled switch (contacts, coil) | Contactor + overload relay + control circuit |

| Use Case | General power switching | Motor control and protection |

| Cost | Lower | Higher due to added protection |

Introduction to Contactors and Motor Starters

Contactors are electrically controlled switches used to regularly control motors by switching power circuits on and off, designed to handle high current loads safely. Motor starters integrate a contactor with overload protection devices to both start and protect electric motors from electrical faults such as overheating and short circuits. These devices are essential in industrial automation, ensuring reliable motor operation and extended equipment lifespan.

What is a Contactor?

A contactor is an electrically controlled switch used for switching an electrical power circuit, primarily for controlling electric motors. It operates by using a coil to create a magnetic field that opens or closes the contacts, enabling high-current load switching without manual intervention. Commonly found in industrial automation, contactors provide reliable and safe operation for motor control and other heavy electrical equipment.

What is a Motor Starter?

A motor starter is an electrical device designed to safely start and stop an electric motor by controlling the power supply and providing overload protection. It combines a contactor to switch the motor on and off with an overload relay to prevent motor damage from excessive current. By using a motor starter, your motor operates efficiently while reducing the risk of electrical faults and mechanical wear.

Key Differences Between Contactors and Motor Starters

Contactors serve primarily as electrically controlled switches to manage the flow of power to motors, while motor starters combine contactors with overload protection to safely start and stop motors. Unlike contactors, motor starters include thermal or electronic overload relays that prevent motor damage from excessive current. The key difference lies in motor starters offering comprehensive motor control and protection functions, whereas contactors function mainly as power switching devices without inherent overload protection.

Functional Roles in Electrical Circuits

Contactors primarily function as electrically controlled switches that enable or interrupt power flow in electrical circuits, facilitating remote control of motors and other heavy loads. Motor starters integrate contactors with overload protection devices, ensuring motors receive correct voltage while safeguarding against electrical faults and thermal overload. The combination of switching capability and protective functions in motor starters optimizes operational safety and motor longevity in industrial applications.

Types of Contactors and Motor Starters

Contactors include electromagnetic, vacuum, and solid-state types, each designed for specific load capacities and environmental conditions. Motor starters are primarily classified as direct-on-line (DOL), star-delta, and soft starters, with each type offering different methods of reducing inrush current and protecting motors. Selection depends on application requirements like motor size, starting torque, and control complexity.

Applications and Uses in Industry

Contactors are widely used in industrial automation for switching electrical power circuits, especially in lighting, heating, and motor control applications where remote control and frequent switching are required. Motor starters incorporate contactors along with overload protection devices to safely start and stop motors, making them essential in heavy machinery, conveyor systems, and HVAC equipment. Industries such as manufacturing, mining, and food processing rely on motor starters for motor protection and efficient operation, while contactors serve broader roles in controlling various electrical loads.

Advantages and Disadvantages of Each Device

Contactors offer compact design and fast switching capabilities ideal for remote control of electric motors but can generate electrical noise and may suffer from contact wear over time. Motor starters combine a contactor with an overload relay, providing built-in motor protection against overheating and phase failure, though they tend to be bulkier and more expensive. Understanding the trade-offs between contactors and motor starters helps you optimize motor control and protection for your specific application.

Selecting the Right Device: Contactor vs Motor Starter

Selecting the right device requires understanding that a contactor is primarily designed to switch electrical power circuits on and off, while a motor starter combines a contactor with overload protection to safeguard motors from damage. Your choice depends on whether you need just remote switching (contactor) or full motor protection and control (motor starter). For motor applications, opting for a motor starter ensures both operational control and safety, optimizing performance and longevity.

Conclusion: Choosing the Best Option for Your Needs

Selecting between a contactor and a motor starter depends on your specific application requirements, including control features and safety needs. Motor starters offer overload protection alongside making or breaking circuits, ideal for safeguarding your motor during operation. Contactors provide reliable switching for high-current loads but require separate overload devices, making motor starters the better all-in-one choice for most motor control scenarios.

Contactor vs Motor Starter Infographic

electrown.com

electrown.com