Hardwired interlocks provide immediate, reliable physical control by using dedicated circuits to prevent unsafe machine operations, ensuring safety without software dependencies. Software interlocks offer flexible, programmable safety measures but can be vulnerable to software errors, making it essential for you to understand their differences before implementing a system; read on to explore the detailed comparison.

Table of Comparison

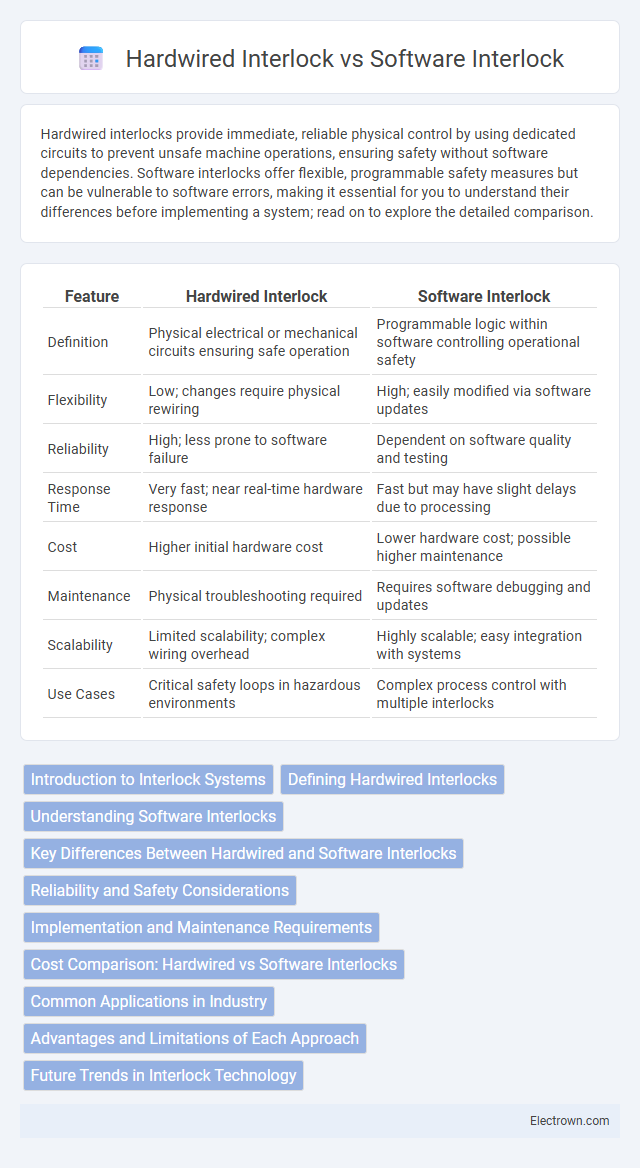

| Feature | Hardwired Interlock | Software Interlock |

|---|---|---|

| Definition | Physical electrical or mechanical circuits ensuring safe operation | Programmable logic within software controlling operational safety |

| Flexibility | Low; changes require physical rewiring | High; easily modified via software updates |

| Reliability | High; less prone to software failure | Dependent on software quality and testing |

| Response Time | Very fast; near real-time hardware response | Fast but may have slight delays due to processing |

| Cost | Higher initial hardware cost | Lower hardware cost; possible higher maintenance |

| Maintenance | Physical troubleshooting required | Requires software debugging and updates |

| Scalability | Limited scalability; complex wiring overhead | Highly scalable; easy integration with systems |

| Use Cases | Critical safety loops in hazardous environments | Complex process control with multiple interlocks |

Introduction to Interlock Systems

Interlock systems serve as critical safety mechanisms designed to prevent hazardous operations by ensuring specific conditions are met before machinery or processes activate. Hardwired interlocks use physical electrical circuits and relays to enforce safe machine states, providing reliable, fast response times and immunity to software failures. Software interlocks rely on programmable logic controllers (PLCs) or embedded software to monitor conditions and control equipment, offering greater flexibility and easy modifications but requiring rigorous validation to mitigate risks associated with software errors.

Defining Hardwired Interlocks

Hardwired interlocks are physical, electrical connections designed to prevent unsafe machine operations by interrupting power or control circuits when specific conditions are not met. These interlocks rely on mechanical relays, switches, and wiring to enforce safety protocols, offering reliable, immediate response without software dependency. Your choice between hardwired and software interlocks depends on the criticality of safety requirements and the need for fail-safe, tamper-resistant control measures.

Understanding Software Interlocks

Software interlocks provide flexible control mechanisms by executing safety logic within programmable controllers, allowing real-time monitoring and adjustment of system parameters to prevent hazardous conditions. Unlike hardwired interlocks that rely on physical electrical circuits, software interlocks enable complex sequencing and diagnostics, enhancing system reliability and ease of updates. Understanding software interlocks empowers you to implement adaptive safety measures that improve operational efficiency while maintaining strict compliance with industry safety standards.

Key Differences Between Hardwired and Software Interlocks

Hardwired interlocks use physical components such as relays and switches to enforce safety protocols, providing immediate, fail-safe operation with minimal latency. Software interlocks rely on programmable logic controllers (PLCs) or embedded software for control, offering flexibility and easier modifications but potentially introducing latency and software bugs. Key differences include response time, reliability under fault conditions, and ease of updates, with hardwired systems excelling in real-time safety and software interlocks enabling complex logic and remote management.

Reliability and Safety Considerations

Hardwired interlocks offer superior reliability and safety due to their physical circuitry, minimizing the risk of malfunction from software errors or cyber threats. In contrast, software interlocks provide flexibility and easier updates but may be vulnerable to bugs, hacking, or system crashes that compromise safety. To ensure optimal protection, your critical safety systems should prioritize hardwired interlocks where fail-safe operation is essential.

Implementation and Maintenance Requirements

Hardwired interlocks require physical wiring and mechanical components, demanding precise installation and regular manual inspections to ensure reliability, which can increase maintenance complexity and downtime. Software interlocks rely on programmable logic controllers or embedded systems, allowing easier updates and modifications through code changes but necessitating thorough validation and testing to prevent software bugs or cyber vulnerabilities. Maintenance of hardwired systems often involves hardware replacements, while software interlocks focus on patch management and version control to maintain operational safety and compliance standards.

Cost Comparison: Hardwired vs Software Interlocks

Hardwired interlocks typically involve higher initial installation costs due to physical components, wiring, and labor expenses, whereas software interlocks leverage existing digital infrastructure, reducing upfront investment. Maintenance costs for hardwired interlocks can be significant, requiring manual troubleshooting and hardware replacement, while software interlocks benefit from remote diagnostics and easier updates, lowering long-term operational expenses. Your choice depends on balancing the higher upfront costs of hardwired systems against the scalable, cost-effective nature of software-based interlocks.

Common Applications in Industry

Hardwired interlocks are extensively used in heavy machinery and safety-critical industrial environments such as power plants and manufacturing lines where immediate physical disconnection is crucial. Software interlocks find common applications in automated systems, robotics, and process control industries where flexible, programmable safety protocols are essential. Both systems ensure operational safety but differ in adaptability and maintenance requirements depending on the industrial context.

Advantages and Limitations of Each Approach

Hardwired interlocks offer reliable, real-time protection through dedicated physical circuits, ensuring immediate response and high safety integrity levels, but they lack flexibility and are costly to modify once implemented. Software interlocks provide adaptable, programmable control with easy updates and integration into complex systems, yet they depend on processor reliability, are vulnerable to software bugs, and may introduce latency in critical safety responses. Choosing between hardwired and software interlocks involves balancing robustness, maintainability, and system complexity to meet specific safety and operational requirements.

Future Trends in Interlock Technology

Future trends in interlock technology emphasize the integration of advanced software interlock systems with machine learning algorithms to enhance predictive maintenance and real-time safety monitoring. Hardwired interlocks continue to provide reliable fail-safe mechanisms, but the shift toward smart IoT-enabled software interlocks enables greater flexibility, remote diagnostics, and adaptive control in industrial automation. Emerging technologies like edge computing and AI-driven analytics further revolutionize interlock systems, optimizing operational efficiency and minimizing downtime.

Hardwired Interlock vs Software Interlock Infographic

electrown.com

electrown.com