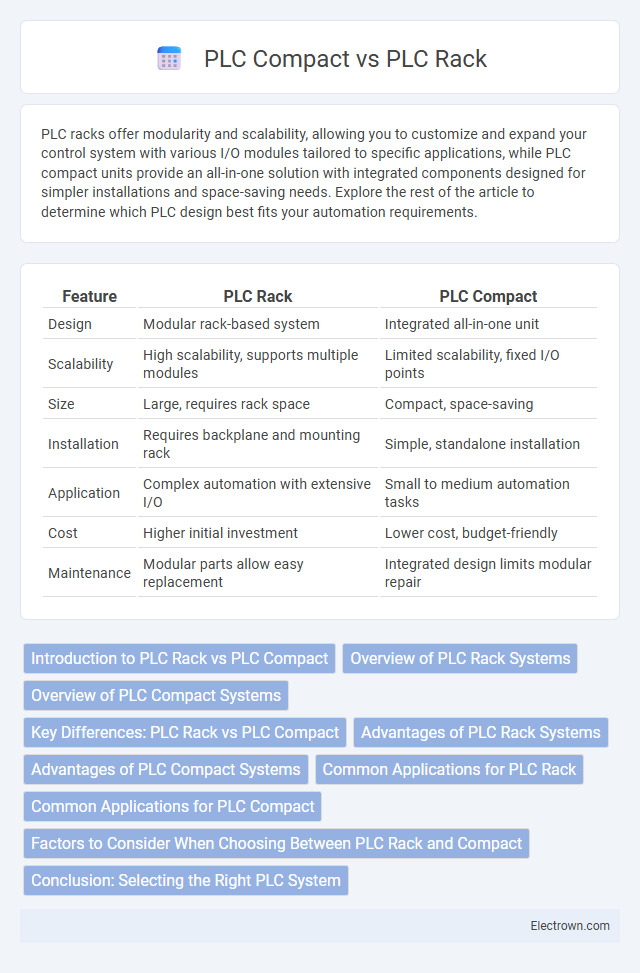

PLC racks offer modularity and scalability, allowing you to customize and expand your control system with various I/O modules tailored to specific applications, while PLC compact units provide an all-in-one solution with integrated components designed for simpler installations and space-saving needs. Explore the rest of the article to determine which PLC design best fits your automation requirements.

Table of Comparison

| Feature | PLC Rack | PLC Compact |

|---|---|---|

| Design | Modular rack-based system | Integrated all-in-one unit |

| Scalability | High scalability, supports multiple modules | Limited scalability, fixed I/O points |

| Size | Large, requires rack space | Compact, space-saving |

| Installation | Requires backplane and mounting rack | Simple, standalone installation |

| Application | Complex automation with extensive I/O | Small to medium automation tasks |

| Cost | Higher initial investment | Lower cost, budget-friendly |

| Maintenance | Modular parts allow easy replacement | Integrated design limits modular repair |

Introduction to PLC Rack vs PLC Compact

PLC Rack systems offer modular design flexibility with multiple slots for various I/O modules, ideal for large-scale industrial automation requiring customization and expansion. PLC Compact units integrate the CPU and I/O modules into a single enclosure, saving space and simplifying installation for smaller or medium-sized applications. Your choice between PLC Rack and PLC Compact depends on the complexity, scalability, and space constraints of your automation project.

Overview of PLC Rack Systems

PLC rack systems consist of modular components housed within a standardized frame, allowing easy expansion and customization to meet complex automation needs. These systems offer high flexibility with interchangeable modules such as CPUs, power supplies, and I/O units, ideal for large-scale industrial applications. Your control setup benefits from enhanced scalability and maintenance efficiency compared to compact PLCs, which integrate all functions into a single unit.

Overview of PLC Compact Systems

PLC Compact systems integrate essential automation components into a single, space-saving unit designed for efficient control in smaller applications. These systems typically combine the CPU, power supply, and I/O modules into a unified housing, reducing wiring complexity and installation time. Your choice of a PLC Compact offers streamlined deployment and maintenance advantages compared to traditional PLC rack configurations.

Key Differences: PLC Rack vs PLC Compact

PLC Rack systems offer modularity with multiple slots for various I/O modules and processors, providing greater flexibility and scalability for complex industrial applications. PLC Compact units integrate the CPU, power supply, and I/O into a single housing, making them more space-efficient and easier to install for smaller, less complex tasks. Your choice depends on the need for expandability versus simplicity and space-saving in your automation setup.

Advantages of PLC Rack Systems

PLC rack systems offer superior scalability and flexibility, allowing for easy addition or replacement of modules without major hardware changes. Their modular design supports complex automation tasks and integrates seamlessly with various input/output configurations, enhancing system customization. You benefit from improved maintainability and fault isolation due to the distinct separation of individual components within the rack.

Advantages of PLC Compact Systems

PLC Compact systems offer significant space-saving advantages by integrating the CPU, power supply, and I/O modules into a single unit, reducing installation complexity. These systems provide enhanced reliability due to fewer wiring connections and simpler configurations compared to PLC rack systems. Maintenance is streamlined, with faster diagnostics and easier replacement, making PLC Compact ideal for smaller applications and limited-space environments.

Common Applications for PLC Rack

PLC Rack systems are widely used in complex industrial automation settings such as manufacturing plants, process control, and large-scale assembly lines where scalability and modularity are essential. These systems support multiple I/O modules and specialized cards, allowing tailored configurations for applications demanding high processing power and extensive input/output capacity. Your control infrastructure benefits from the flexibility and expandability offered by PLC Rack designs, making them ideal for handling diverse and evolving automation tasks.

Common Applications for PLC Compact

PLC Compact units are widely used in small to medium automation projects such as packaging machines, conveyor controls, and building management systems due to their integrated input/output modules and minimal footprint. These controllers excel in applications requiring rapid deployment and limited expansion, like HVAC systems and simple assembly lines. Their cost-effectiveness and ease of programming make them ideal for tasks where space and budget constraints are critical.

Factors to Consider When Choosing Between PLC Rack and Compact

Evaluating PLC Rack versus PLC Compact involves considering space availability, scalability requirements, and application complexity. PLC Rack systems offer modularity and easy expansion for large, complex operations, while PLC Compact units provide a smaller footprint ideal for simpler, space-constrained setups. Your choice depends on the balance between current needs and future growth, ensuring optimal performance and cost-efficiency.

Conclusion: Selecting the Right PLC System

Choosing between a PLC rack and a PLC compact system depends on your project's scale and complexity. PLC rack systems offer high modularity and scalability, ideal for large industrial automation requiring extensive I/O and flexibility. Your decision should align with space constraints, budget, and future expansion needs to ensure optimal control system performance.

PLC Rack vs PLC Compact Infographic

electrown.com

electrown.com