Encoders convert motion into an electrical signal to provide position feedback with high accuracy, while resolvers use electromagnetic induction to generate analog signals for robust and reliable position sensing in harsh environments. Explore this article to understand how choosing between an encoder and a resolver can impact your system's performance and reliability.

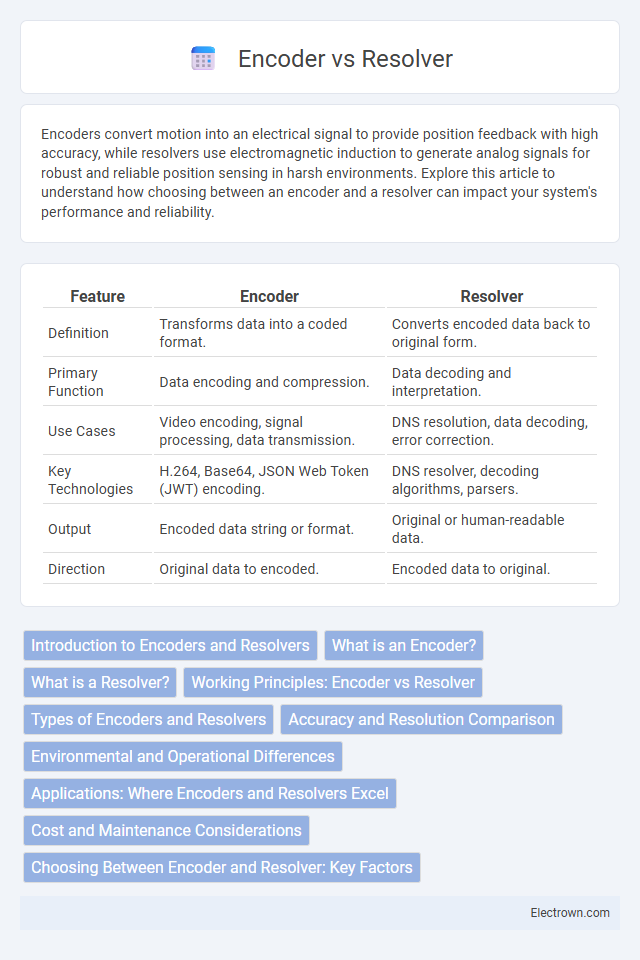

Table of Comparison

| Feature | Encoder | Resolver |

|---|---|---|

| Definition | Transforms data into a coded format. | Converts encoded data back to original form. |

| Primary Function | Data encoding and compression. | Data decoding and interpretation. |

| Use Cases | Video encoding, signal processing, data transmission. | DNS resolution, data decoding, error correction. |

| Key Technologies | H.264, Base64, JSON Web Token (JWT) encoding. | DNS resolver, decoding algorithms, parsers. |

| Output | Encoded data string or format. | Original or human-readable data. |

| Direction | Original data to encoded. | Encoded data to original. |

Introduction to Encoders and Resolvers

Encoders convert mechanical motion into electrical signals to measure position or speed, commonly used in automation and robotics for precise control. Resolvers function as analog sensors providing absolute position feedback through electromagnetic induction, excelling in harsh environments due to their robustness. Your choice depends on application requirements for accuracy, environmental conditions, and signal type needed for optimal performance.

What is an Encoder?

An encoder is an electromechanical device that converts the angular position or motion of a shaft into an analog or digital signal, enabling precise measurement of rotation, speed, and direction. Common types include optical and magnetic encoders, which provide feedback in automation, robotics, and motion control systems. Understanding how your encoder functions ensures accurate data for synchronization and control in complex machinery.

What is a Resolver?

A resolver is a software component that processes and interprets data references or queries, transforming them into actionable information or values within a system. It functions by mapping identifiers or symbolic names to corresponding resources, enabling dynamic data retrieval and resolution during runtime. In contrast with encoders that translate data into specific formats, resolvers focus on locating and providing the actual data linked to references, playing a crucial role in dependency injection, service discovery, and DNS lookups.

Working Principles: Encoder vs Resolver

Encoders convert mechanical motion into electronic signals by using optical or magnetic sensors to detect angular position or displacement, providing precise digital output for control systems. Resolvers operate as analog devices using electromagnetic induction to produce sine and cosine signals proportional to shaft position, offering robust performance in harsh environments. Your choice depends on the required accuracy, environment, and signal type, with encoders favoring digital precision and resolvers excelling in durability and noise resistance.

Types of Encoders and Resolvers

Encoders come in several types, including incremental and absolute encoders, each offering distinct feedback mechanisms for position and speed measurement in automation systems. Resolvers, primarily classified into brushless and rotary transformers, provide robust analog feedback ideal for harsh environments due to their durability and precise angular position data. Your choice between these depends on application requirements such as precision, environmental conditions, and signal type compatibility.

Accuracy and Resolution Comparison

Encoders typically offer higher resolution and accuracy by converting mechanical motion into precise digital signals, commonly used in applications requiring fine position detection. Resolvers provide robust, analog output signals with moderate resolution, excelling in harsh environments where reliability and noise immunity are critical. Your choice depends on the need for precise measurement accuracy versus durability and environmental tolerance.

Environmental and Operational Differences

Encoders and resolvers differ significantly in environmental and operational performance; encoders are typically sensitive to dust, dirt, and moisture, making them better suited for clean environments. Resolvers operate effectively in harsh conditions with high levels of vibration, extreme temperatures, and electromagnetic interference due to their robust construction and analog signal output. Understanding these differences helps you select the appropriate device based on your specific environmental and operational requirements.

Applications: Where Encoders and Resolvers Excel

Encoders excel in applications requiring precise digital position feedback, such as robotics, automated machinery, and CNC tools, where accurate speed and position control are critical. Resolvers are preferred in harsh environments like aerospace, military systems, and industrial motors due to their robust construction and resilience to extreme temperatures, vibration, and electromagnetic interference. Your choice depends on whether precision digital output or durability under challenging conditions is paramount.

Cost and Maintenance Considerations

Encoders generally come at a lower upfront cost compared to resolvers, making them a budget-friendly option for many applications. Maintenance requirements for encoders tend to be higher due to their sensitivity to dust and physical wear, which can lead to more frequent replacements or repairs. Your choice should consider ongoing maintenance expenses, as resolvers offer greater durability and reliability in harsh environments, potentially reducing long-term costs.

Choosing Between Encoder and Resolver: Key Factors

Choosing between an encoder and a resolver depends primarily on factors like environmental conditions, accuracy requirements, and system complexity. Encoders offer high resolution and easy integration for precise position feedback, while resolvers excel in harsh environments due to their robust, noise-immune analog signals. Your decision should consider whether your application prioritizes durability in extreme conditions or ultra-precise digital feedback.

Encoder vs Resolver Infographic

electrown.com

electrown.com