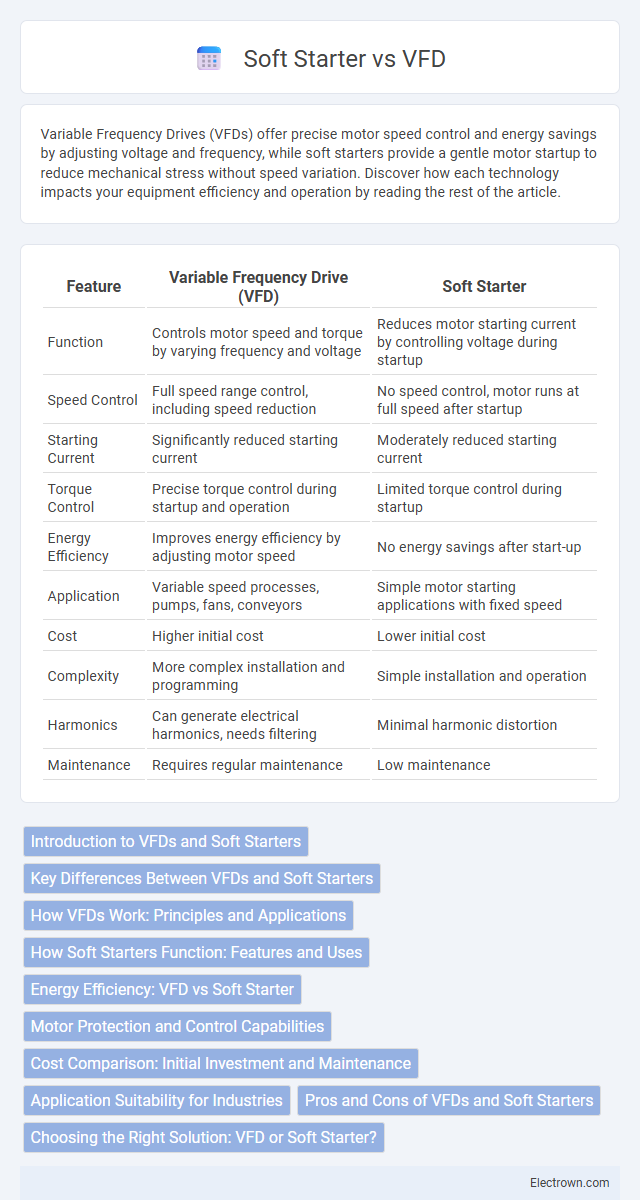

Variable Frequency Drives (VFDs) offer precise motor speed control and energy savings by adjusting voltage and frequency, while soft starters provide a gentle motor startup to reduce mechanical stress without speed variation. Discover how each technology impacts your equipment efficiency and operation by reading the rest of the article.

Table of Comparison

| Feature | Variable Frequency Drive (VFD) | Soft Starter |

|---|---|---|

| Function | Controls motor speed and torque by varying frequency and voltage | Reduces motor starting current by controlling voltage during startup |

| Speed Control | Full speed range control, including speed reduction | No speed control, motor runs at full speed after startup |

| Starting Current | Significantly reduced starting current | Moderately reduced starting current |

| Torque Control | Precise torque control during startup and operation | Limited torque control during startup |

| Energy Efficiency | Improves energy efficiency by adjusting motor speed | No energy savings after start-up |

| Application | Variable speed processes, pumps, fans, conveyors | Simple motor starting applications with fixed speed |

| Cost | Higher initial cost | Lower initial cost |

| Complexity | More complex installation and programming | Simple installation and operation |

| Harmonics | Can generate electrical harmonics, needs filtering | Minimal harmonic distortion |

| Maintenance | Requires regular maintenance | Low maintenance |

Introduction to VFDs and Soft Starters

Variable Frequency Drives (VFDs) control motor speed and torque by varying frequency and voltage, enhancing energy efficiency and process precision. Soft Starters gradually ramp up voltage to reduce inrush current during motor startup, minimizing mechanical stress and electrical demand. Your choice depends on specific application needs such as speed control or smooth starting performance.

Key Differences Between VFDs and Soft Starters

VFDs (Variable Frequency Drives) control motor speed and torque by varying electrical frequency and voltage, enabling precise speed regulation and energy savings, while soft starters limit inrush current during motor startup to reduce mechanical stress without speed control. Soft starters are simpler and more cost-effective for applications requiring smooth starts and stops, but lack the advanced speed modulation features of VFDs. Your choice depends on whether speed control or reduced startup stress is the primary operational need.

How VFDs Work: Principles and Applications

Variable Frequency Drives (VFDs) control the speed and torque of AC motors by varying the frequency and voltage of the electrical power supplied. They use pulse width modulation (PWM) to convert fixed-frequency AC power into adjustable frequency output, enabling precise motor control that improves energy efficiency in applications like conveyors, pumps, and HVAC systems. This adaptability contrasts with soft starters, which only reduce inrush current during motor startup without altering motor speed.

How Soft Starters Function: Features and Uses

Soft starters function by gradually increasing the voltage supplied to an electric motor, reducing inrush current and mechanical stress during startup. Key features include reduced electrical and mechanical wear, adjustable start and stop times, and protection against overload and phase loss, making them ideal for applications like conveyors, pumps, and compressors. Your equipment benefits from smoother, more efficient startups, extending motor lifespan and minimizing maintenance costs.

Energy Efficiency: VFD vs Soft Starter

Variable Frequency Drives (VFDs) offer superior energy efficiency compared to soft starters by continuously adjusting motor speed to match load requirements, reducing power consumption significantly. Soft starters only manage inrush current during motor startup without controlling motor speed, resulting in no energy savings during normal operation. Implementing VFDs can lead to energy savings of up to 30% in variable load applications, whereas soft starters primarily protect the motor without optimizing energy use.

Motor Protection and Control Capabilities

Variable Frequency Drives (VFDs) offer advanced motor protection features such as overload protection, stall prevention, and programmable acceleration/deceleration profiles, enhancing precise control and reducing mechanical stress. Soft starters primarily provide controlled ramp-up voltage to limit inrush current and reduce mechanical wear but lack comprehensive control over speed and torque. VFDs enable superior motor speed regulation, energy savings, and dynamic load handling, making them ideal for applications requiring fine motor control and enhanced protection.

Cost Comparison: Initial Investment and Maintenance

Variable Frequency Drives (VFDs) typically require a higher initial investment than soft starters due to their complex electronic components and advanced control features. Maintenance costs for VFDs can be higher as well, given their sensitivity to environmental factors and the need for specialized diagnostics and repairs. In contrast, soft starters generally involve lower upfront costs and simpler maintenance, making them cost-effective for applications with straightforward motor starting requirements.

Application Suitability for Industries

VFDs (Variable Frequency Drives) are highly suitable for industries requiring precise speed control and energy efficiency, such as HVAC, manufacturing, and mining. Soft starters excel in applications where smooth motor startup and reduced mechanical stress are critical, making them ideal for pumps, compressors, and conveyor systems. Your choice depends on whether you prioritize advanced motor control or simple, cost-effective startup protection.

Pros and Cons of VFDs and Soft Starters

Variable Frequency Drives (VFDs) offer precise speed control and energy savings by adjusting motor speed to match load requirements, but they involve higher initial costs and complex installation. Soft starters provide a cost-effective solution to reduce inrush current and mechanical stress during motor startups, yet they lack speed control capabilities and can cause higher energy consumption during operation. Understanding your system's needs helps determine whether a VFD's efficiency benefits or the simplicity of a soft starter better suits your application.

Choosing the Right Solution: VFD or Soft Starter?

Choosing between a Variable Frequency Drive (VFD) and a Soft Starter depends on the application requirements such as speed control, energy efficiency, and motor protection. VFDs offer precise speed regulation and energy savings by adjusting motor frequency, making them ideal for processes requiring variable speed operation. Soft Starters provide smooth starting current reduction and motor protection without continuous speed control, suitable for applications with frequent starts and stops but constant speed operation.

VFD vs Soft Starter Infographic

electrown.com

electrown.com