Y-Delta starters reduce the initial starting current and torque of motors by switching from a star to a delta connection, effectively minimizing electrical stress during startup, while auto transformer starters accomplish this by using transformers to decrease voltage applied to the motor, offering smoother acceleration and better control. Discover how each method impacts motor performance and which one suits your specific needs by reading the rest of the article.

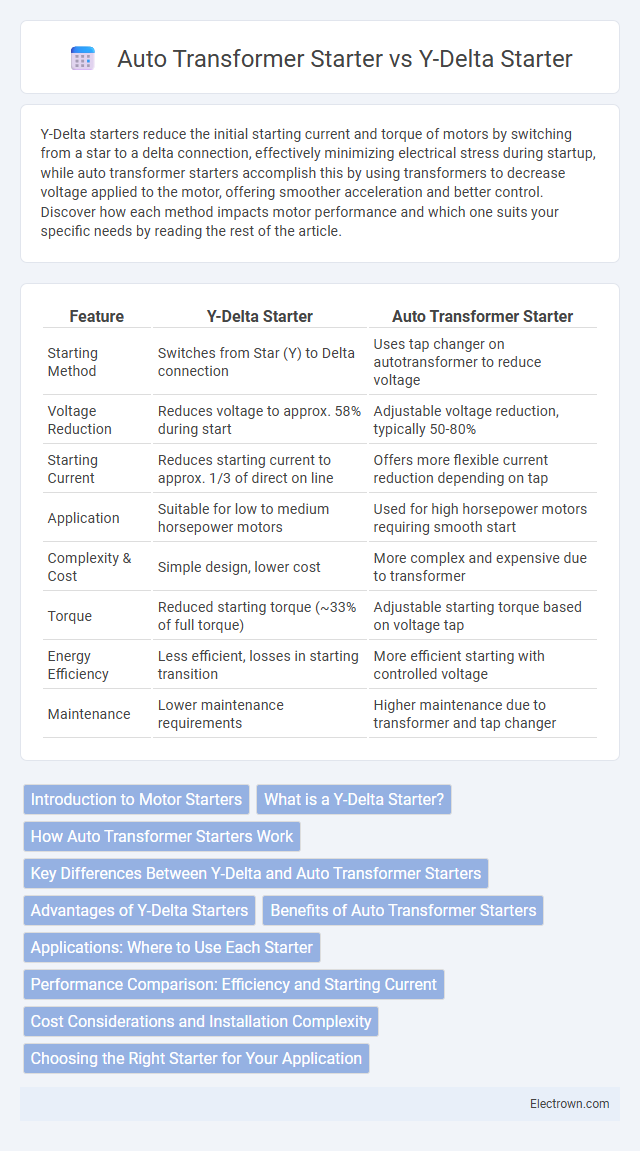

Table of Comparison

| Feature | Y-Delta Starter | Auto Transformer Starter |

|---|---|---|

| Starting Method | Switches from Star (Y) to Delta connection | Uses tap changer on autotransformer to reduce voltage |

| Voltage Reduction | Reduces voltage to approx. 58% during start | Adjustable voltage reduction, typically 50-80% |

| Starting Current | Reduces starting current to approx. 1/3 of direct on line | Offers more flexible current reduction depending on tap |

| Application | Suitable for low to medium horsepower motors | Used for high horsepower motors requiring smooth start |

| Complexity & Cost | Simple design, lower cost | More complex and expensive due to transformer |

| Torque | Reduced starting torque (~33% of full torque) | Adjustable starting torque based on voltage tap |

| Energy Efficiency | Less efficient, losses in starting transition | More efficient starting with controlled voltage |

| Maintenance | Lower maintenance requirements | Higher maintenance due to transformer and tap changer |

Introduction to Motor Starters

Motor starters are essential devices that control the starting and stopping of electric motors, ensuring smooth operation and protection from electrical faults. Y-Delta Starters reduce the starting current by initially connecting the motor windings in a star configuration, then switching to delta for full load operation, making them ideal for motors with moderate starting torque requirements. Auto Transformer Starters use a variable voltage transformer to provide a reduced voltage start, offering better control over starting current and torque, which suits heavy-duty motors and applications demanding a more flexible starting method.

What is a Y-Delta Starter?

A Y-Delta starter is an electrical device used to reduce the starting current of induction motors by initially connecting the motor windings in a star (Y) configuration, which lowers voltage and current, then switching to a delta configuration for normal operation. This method minimizes mechanical stress and electrical surges, making it ideal for motors with rated power between 5 to 35 kW. Your motor benefits from smoother startup and enhanced protection against voltage fluctuations using a Y-Delta starter compared to an autotransformer starter.

How Auto Transformer Starters Work

Auto transformer starters reduce the initial voltage applied to the motor by tapping a part of the transformer winding, providing a stepped voltage that gradually increases during startup. This reduction in starting current minimizes mechanical stress and electrical demand, enhancing motor protection and energy efficiency. The auto transformer adjusts the voltage smoothly until full supply voltage is applied, improving the motor's acceleration and overall operational stability.

Key Differences Between Y-Delta and Auto Transformer Starters

Y-Delta starters reduce the initial starting current by switching the motor windings from a star (Y) configuration to a delta (D) configuration after the motor reaches a preset speed, which is ideal for applications requiring moderate starting torque. Auto transformer starters use variable voltage tap settings to provide a reduced voltage start, offering higher starting torque and better control over current and voltage levels. Choosing between the two depends on your motor's torque requirements and system design, with Y-Delta starters typically suited for smaller motors and auto transformer starters preferred for larger motors requiring higher starting torque.

Advantages of Y-Delta Starters

Y-Delta starters reduce the starting current to approximately one-third of the full-load current, minimizing electrical stress on your motor and the power supply. They provide a simple and cost-effective solution for starting three-phase induction motors with a lower initial torque but sufficient for many industrial applications. This method improves motor longevity by reducing thermal and mechanical stress during startup.

Benefits of Auto Transformer Starters

Auto Transformer Starters significantly reduce the starting current and torque of large induction motors, minimizing electrical and mechanical stress during startup. This leads to enhanced motor lifespan and decreased maintenance costs compared to Y-Delta Starters. Their ability to provide multiple voltage tapping options allows precise control of starting voltage, improving energy efficiency and operational flexibility.

Applications: Where to Use Each Starter

Y-Delta starters are ideal for starting large squirrel-cage induction motors in industries like manufacturing and HVAC where reduced starting current and torque are crucial to protect mechanical parts and electrical networks. Auto transformer starters excel in applications requiring adjustable voltage start, such as heavy machinery and large pumps, providing smooth acceleration with customizable voltage steps to minimize electrical stress. Your choice depends on the motor size, load characteristics, and the need for adjustable voltage control during startup.

Performance Comparison: Efficiency and Starting Current

Y-Delta Starters typically offer lower starting current by initially connecting the motor windings in a Y configuration, reducing voltage and current during startup, which enhances efficiency in applications requiring reduced mechanical stress. Auto Transformer Starters provide adjustable voltage levels during startup, offering more flexibility and better control over starting current, often resulting in higher efficiency for motors with varying load demands. Your choice depends on the specific application needs, with Auto Transformer Starters generally delivering improved performance in efficiency and starting current modulation compared to Y-Delta Starters.

Cost Considerations and Installation Complexity

Y-Delta starters generally offer lower initial costs and simpler installation processes compared to auto transformer starters, which involve higher expenses due to more complex winding arrangements and additional components. Installation of Y-Delta starters requires less space and fewer connections, making it more straightforward for standard motor applications. Your choice between these starters should consider the balance between upfront investment and the specific electrical characteristics needed for your equipment.

Choosing the Right Starter for Your Application

Y-Delta starters reduce initial motor current and torque by initially connecting the motor windings in a star configuration before switching to delta for normal operation, making them ideal for applications with lower starting torque requirements. Auto transformer starters provide adjustable voltage taps to limit starting current, offering smoother acceleration and better control for motors with higher starting torque demands or heavy load conditions. Selecting the appropriate starter depends on factors such as motor size, load characteristics, starting current limits, and the required torque profile for the specific industrial application.

Y-Delta Starter vs Auto Transformer Starter Infographic

electrown.com

electrown.com