Fiber optic sensors offer unparalleled sensitivity and immunity to electromagnetic interference, making them ideal for precise detection in harsh environments, while capacitive proximity sensors excel in detecting non-metallic objects and changes in material composition through variations in capacitance. Discover which sensor type best suits your application by exploring the detailed comparisons and use cases in the rest of the article.

Table of Comparison

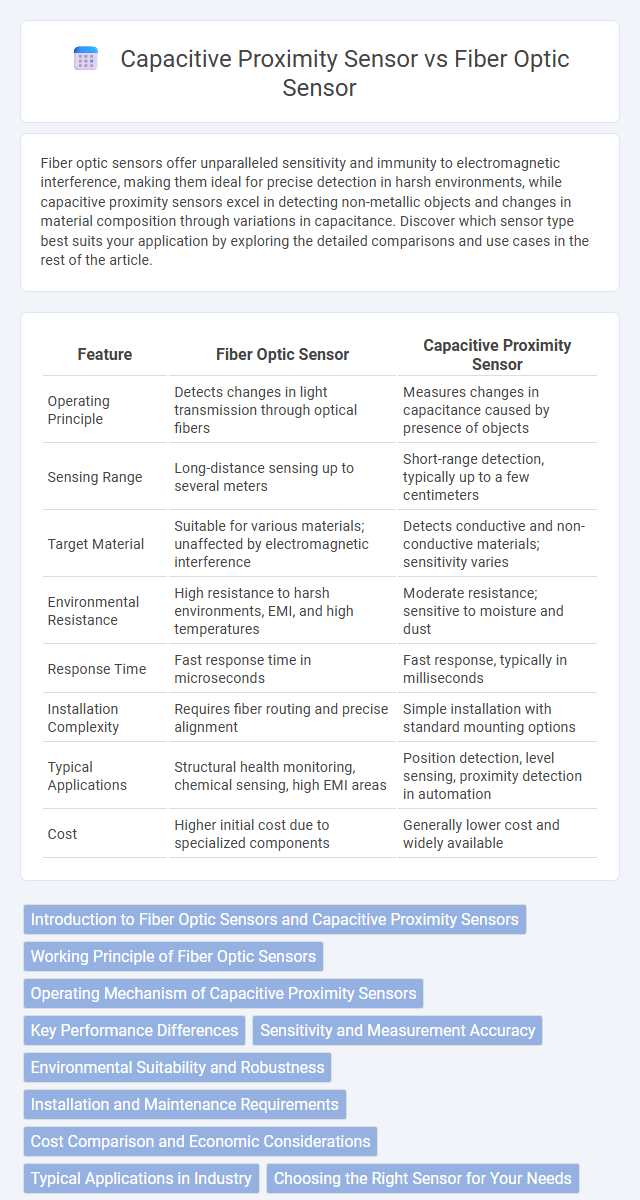

| Feature | Fiber Optic Sensor | Capacitive Proximity Sensor |

|---|---|---|

| Operating Principle | Detects changes in light transmission through optical fibers | Measures changes in capacitance caused by presence of objects |

| Sensing Range | Long-distance sensing up to several meters | Short-range detection, typically up to a few centimeters |

| Target Material | Suitable for various materials; unaffected by electromagnetic interference | Detects conductive and non-conductive materials; sensitivity varies |

| Environmental Resistance | High resistance to harsh environments, EMI, and high temperatures | Moderate resistance; sensitive to moisture and dust |

| Response Time | Fast response time in microseconds | Fast response, typically in milliseconds |

| Installation Complexity | Requires fiber routing and precise alignment | Simple installation with standard mounting options |

| Typical Applications | Structural health monitoring, chemical sensing, high EMI areas | Position detection, level sensing, proximity detection in automation |

| Cost | Higher initial cost due to specialized components | Generally lower cost and widely available |

Introduction to Fiber Optic Sensors and Capacitive Proximity Sensors

Fiber optic sensors utilize light signals transmitted through optical fibers to detect changes in temperature, pressure, or displacement with high precision and immunity to electromagnetic interference. Capacitive proximity sensors operate by measuring changes in capacitance caused by the presence or absence of a target object, offering reliable detection of conductive and non-conductive materials at short ranges. These sensor technologies serve diverse applications in industrial automation, with fiber optic sensors excelling in hazardous or high-voltage environments and capacitive sensors widely used for object detection and level sensing.

Working Principle of Fiber Optic Sensors

Fiber optic sensors detect changes in light transmission through optical fibers caused by variations in physical parameters such as temperature, pressure, or displacement. These sensors operate on the principle of modulating light intensity, phase, or wavelength as the environmental condition alters the fiber's properties. Unlike capacitive proximity sensors that rely on changes in capacitance to detect nearby objects, fiber optic sensors offer immunity to electromagnetic interference and can function in harsh or explosive environments.

Operating Mechanism of Capacitive Proximity Sensors

Capacitive proximity sensors operate by detecting changes in the capacitance between the sensor's electrode and the target object, which alters the electric field when a conductive or dielectric material approaches. This mechanism allows the sensor to sense a wide range of materials, including liquids, powders, and solids, making it versatile for different applications. Your choice between fiber optic sensors and capacitive proximity sensors should consider these operational differences and their suitability for your specific environment.

Key Performance Differences

Fiber optic sensors offer high sensitivity and immunity to electromagnetic interference, making them ideal for precise detection in harsh environments. Capacitive proximity sensors provide reliable non-contact detection of conductive and non-conductive materials with adjustable sensing ranges, but their performance may degrade near metallic objects. Fiber optic technology excels in high-speed response and miniaturization, whereas capacitive sensors are favored for cost-effective and versatile proximity detection applications.

Sensitivity and Measurement Accuracy

Fiber optic sensors provide superior sensitivity and measurement accuracy due to their ability to detect minute changes in light signals, making them ideal for precise, long-distance applications. Capacitive proximity sensors offer reliable detection of conductive and non-conductive materials but generally have lower sensitivity and are more affected by environmental factors such as humidity and dust. Your choice should consider the application's required precision and environmental conditions to achieve optimal sensor performance.

Environmental Suitability and Robustness

Fiber optic sensors offer superior environmental suitability and robustness compared to capacitive proximity sensors, as they are highly resistant to electromagnetic interference, extreme temperatures, and corrosive environments, making them ideal for harsh industrial applications. Capacitive proximity sensors, while effective for detecting non-metallic objects and changes in dielectric constants, are more susceptible to environmental factors such as moisture, dust, and temperature fluctuations, which can affect their accuracy and reliability. The inherent durability and immunity of fiber optic sensors to harsh conditions ensure consistent performance in challenging settings where capacitive sensors might fail.

Installation and Maintenance Requirements

Fiber optic sensors require precise alignment during installation and often need specialized tools for maintenance due to their delicate fiber cables and connectors. Capacitive proximity sensors offer easier installation with simple mounting and minimal wiring, making maintenance straightforward and less frequent. Your choice should consider the application environment and the level of technical support available for upkeep.

Cost Comparison and Economic Considerations

Fiber optic sensors generally have higher initial costs due to advanced materials and installation requirements, but they offer superior durability and resistance to harsh environments, reducing long-term maintenance expenses. Capacitive proximity sensors are more affordable upfront and easier to install, making them suitable for cost-sensitive applications with less demanding conditions. Your choice depends on balancing the initial investment against operational savings and reliability needs in the specific industrial context.

Typical Applications in Industry

Fiber optic sensors are extensively used in industries requiring precise, non-contact measurement in environments with high electromagnetic interference, such as petrochemical plants, nuclear power facilities, and medical equipment monitoring. Capacitive proximity sensors excel in detecting non-metallic objects, including liquids, granular materials, and plastics, making them ideal for packaging, food processing, and level detection in tanks. Both sensor types enhance automation and safety, with fiber optic sensors favored for long-distance and hazardous environment sensing, while capacitive sensors are preferred for material presence and position detection in clean industrial settings.

Choosing the Right Sensor for Your Needs

Fiber optic sensors offer high sensitivity and immunity to electromagnetic interference, making them ideal for precise measurements in harsh or confined environments. Capacitive proximity sensors excel in detecting non-metallic objects and measuring changes in material composition, suitable for applications requiring contactless detection of liquids or plastics. Selecting the right sensor depends on factors like environmental conditions, target material, and required precision, where fiber optic sensors are preferred for accuracy and robustness, while capacitive sensors provide versatility in material detection.

fiber optic sensor vs capacitive proximity sensor Infographic

electrown.com

electrown.com