Ratiometric ADCs measure voltage relative to a reference voltage, enhancing accuracy in environments with fluctuating power supply levels, while absolute ADCs provide a direct digital representation of the input voltage independent of any reference. Understanding these differences can help you choose the right ADC type for your specific electronic application--read on to explore their key features and use cases.

Table of Comparison

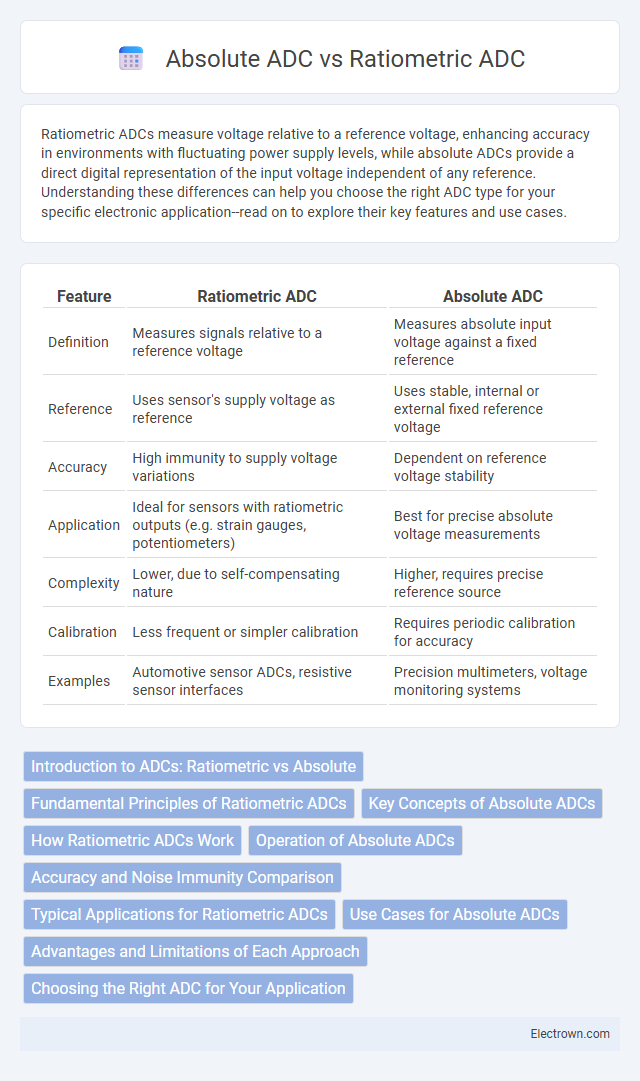

| Feature | Ratiometric ADC | Absolute ADC |

|---|---|---|

| Definition | Measures signals relative to a reference voltage | Measures absolute input voltage against a fixed reference |

| Reference | Uses sensor's supply voltage as reference | Uses stable, internal or external fixed reference voltage |

| Accuracy | High immunity to supply voltage variations | Dependent on reference voltage stability |

| Application | Ideal for sensors with ratiometric outputs (e.g. strain gauges, potentiometers) | Best for precise absolute voltage measurements |

| Complexity | Lower, due to self-compensating nature | Higher, requires precise reference source |

| Calibration | Less frequent or simpler calibration | Requires periodic calibration for accuracy |

| Examples | Automotive sensor ADCs, resistive sensor interfaces | Precision multimeters, voltage monitoring systems |

Introduction to ADCs: Ratiometric vs Absolute

Ratiometric ADCs measure input signals relative to a reference voltage, improving accuracy by reducing the impact of variations in supply voltage and environmental factors. Absolute ADCs convert input signals into a fixed digital value based on a precise internal or external reference, providing direct and consistent output independent of external conditions. Your choice between ratiometric and absolute ADC depends on the application's requirements for precision, noise immunity, and sensor type.

Fundamental Principles of Ratiometric ADCs

Ratiometric ADCs operate by measuring the ratio between an input signal and a reference voltage, effectively canceling out variations in the supply voltage or reference voltage fluctuations. This fundamental principle ensures higher accuracy and stability in environments with unstable power sources. Your measurements benefit from improved precision, especially in sensor applications where the signal is proportional to the supply voltage.

Key Concepts of Absolute ADCs

Absolute ADCs convert analog signals into digital values based on a fixed reference voltage, providing outputs that represent the exact input level regardless of supply variations. These converters use a stable internal or external reference to ensure consistent measurement accuracy. Your applications benefit from absolute ADCs when precise and repeatable voltage quantification is critical, such as in instrumentation and control systems.

How Ratiometric ADCs Work

Ratiometric ADCs measure input signals relative to a reference voltage, minimizing errors caused by supply voltage fluctuations and temperature variations. They convert the ratio between the sensor output and reference voltage into a digital value, enhancing accuracy for sensors like resistive or potentiometric devices. This compensation mechanism ensures that the measurement remains stable even when the absolute supply voltage changes.

Operation of Absolute ADCs

Absolute ADCs convert analog input voltages into a digital output by directly measuring the signal against a fixed reference voltage, generating a unique digital code for each input level. They rely on stable, precise reference sources and internal comparators or successive approximation registers to produce an exact digital representation of the analog input. This method ensures consistent, absolute voltage measurement regardless of variations in power supply or temperature.

Accuracy and Noise Immunity Comparison

Ratiometric ADCs offer enhanced accuracy by measuring input signals relative to a stable reference voltage, effectively canceling out supply voltage variations and reducing errors caused by noise. Absolute ADCs measure the input signal directly against a fixed reference, which can lead to susceptibility in accuracy when the reference voltage fluctuates or noise interferes with the measurement. Your choice of ADC depends on the importance of noise immunity and consistent accuracy in varying power conditions, making ratiometric ADCs preferable for precision sensor applications.

Typical Applications for Ratiometric ADCs

Ratiometric ADCs are commonly used in sensor interfaces where the signal depends on the ratio between two voltages, such as resistive sensors like thermistors, strain gauges, and potentiometers. These ADCs enhance measurement accuracy in environments with fluctuating supply voltages, making them ideal for automotive, industrial automation, and battery-powered devices. Their ability to cancel out supply voltage variations improves the reliability of sensor readings in embedded systems and IoT applications.

Use Cases for Absolute ADCs

Absolute ADCs are essential in applications requiring precise, standalone measurements where external reference signals are unavailable or unreliable, such as temperature sensing and battery monitoring. They provide consistent voltage conversion by comparing input signals against a fixed internal reference, ensuring accuracy in environments with fluctuating conditions. These ADCs are widely used in industrial automation, medical instrumentation, and consumer electronics for reliable data acquisition.

Advantages and Limitations of Each Approach

Ratiometric ADCs offer superior noise immunity and accuracy by measuring input signals relative to a known reference voltage, making them ideal for sensor interfaces where reference fluctuations occur. Absolute ADCs provide direct measurement of input signals relative to a fixed internal reference, enabling simpler system designs and faster conversions but potentially suffering from drift and less noise rejection. Your choice depends on whether precision in varying reference conditions or simplicity and speed in stable environments is the priority.

Choosing the Right ADC for Your Application

Selecting between ratiometric and absolute ADCs depends on the precision and environmental stability required by your application. Ratiometric ADCs offer enhanced noise immunity and accuracy in fluctuating power supply conditions by measuring signals relative to a reference voltage. Absolute ADCs provide direct voltage conversion with fixed references, making them suitable for applications where consistent absolute measurements are critical.

ratiometric ADC vs absolute ADC Infographic

electrown.com

electrown.com