Bridge amplifiers are designed for high-precision strain gauge and sensor measurements, converting minute resistance changes into voltage signals, while instrumentation amplifiers offer high input impedance and excellent noise rejection for accurate low-level signal amplification. Explore this article to understand how each amplifier suits different applications and how your choice impacts measurement accuracy.

Table of Comparison

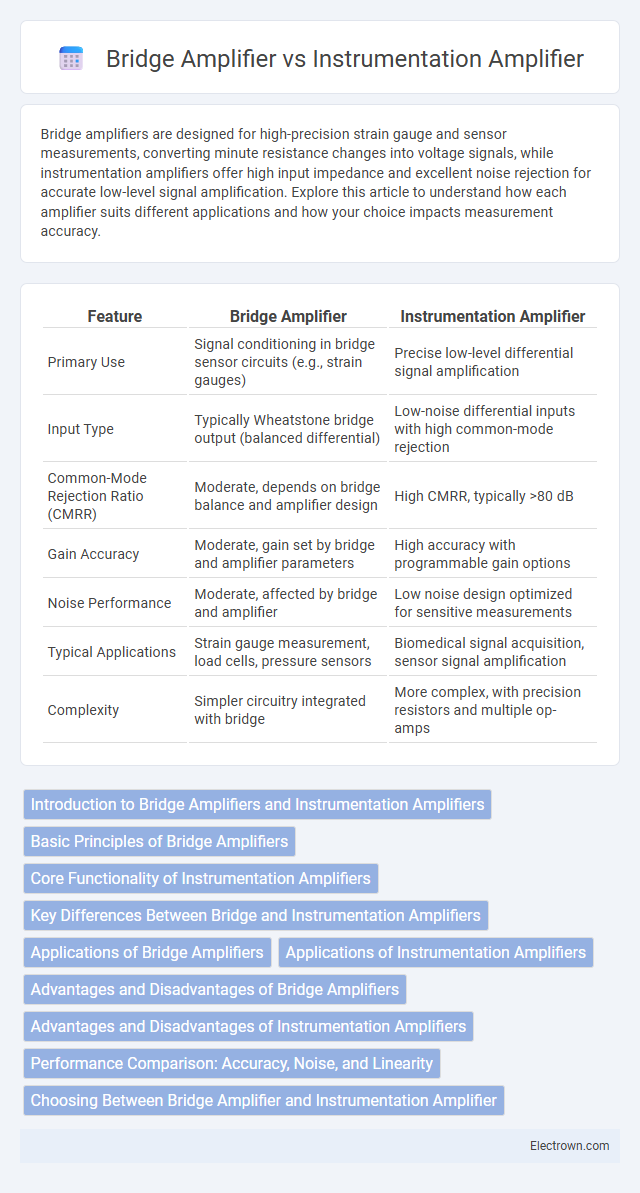

| Feature | Bridge Amplifier | Instrumentation Amplifier |

|---|---|---|

| Primary Use | Signal conditioning in bridge sensor circuits (e.g., strain gauges) | Precise low-level differential signal amplification |

| Input Type | Typically Wheatstone bridge output (balanced differential) | Low-noise differential inputs with high common-mode rejection |

| Common-Mode Rejection Ratio (CMRR) | Moderate, depends on bridge balance and amplifier design | High CMRR, typically >80 dB |

| Gain Accuracy | Moderate, gain set by bridge and amplifier parameters | High accuracy with programmable gain options |

| Noise Performance | Moderate, affected by bridge and amplifier | Low noise design optimized for sensitive measurements |

| Typical Applications | Strain gauge measurement, load cells, pressure sensors | Biomedical signal acquisition, sensor signal amplification |

| Complexity | Simpler circuitry integrated with bridge | More complex, with precision resistors and multiple op-amps |

Introduction to Bridge Amplifiers and Instrumentation Amplifiers

Bridge amplifiers measure small changes in resistance within a Wheatstone bridge circuit, making them ideal for strain gauge and sensor signal conditioning. Instrumentation amplifiers provide high input impedance, low noise, and precise gain accuracy, optimizing differential signal amplification in medical and industrial applications. Both amplifier types enhance signal integrity but are selected based on the specific requirements of sensor output and noise rejection.

Basic Principles of Bridge Amplifiers

Bridge amplifiers operate using a Wheatstone bridge configuration to precisely measure small changes in resistance, often used in sensor applications like strain gauges or load cells. Their basic principle relies on balancing the bridge circuit and amplifying the voltage difference created by resistance variations to produce accurate output signals. Your choice between bridge and instrumentation amplifiers depends on the specific need for high precision resistance measurements and noise rejection in sensor signal conditioning.

Core Functionality of Instrumentation Amplifiers

Instrumentation amplifiers excel at precise, low-noise differential signal amplification, crucial in medical and sensor applications. They offer high input impedance, ensuring minimal signal distortion, and strong common-mode rejection to eliminate noise interference. Unlike bridge amplifiers that convert sensor signals, instrumentation amplifiers enhance signal fidelity for accurate measurement and analysis.

Key Differences Between Bridge and Instrumentation Amplifiers

Bridge amplifiers are primarily designed for measuring small resistance changes in sensor elements like strain gauges, utilizing a Wheatstone bridge configuration to convert resistance variations into voltage signals. Instrumentation amplifiers offer high input impedance, precise gain control, and excellent common-mode rejection ratio (CMRR), making them ideal for amplifying low-level differential signals from various sensors with minimal noise interference. Unlike bridge amplifiers, instrumentation amplifiers provide greater flexibility in gain adjustment and signal conditioning in diverse biomedical, industrial, and measurement applications.

Applications of Bridge Amplifiers

Bridge amplifiers are extensively used in sensor signal conditioning, particularly for strain gauges, load cells, and pressure sensors, where precise measurement of small differential signals is critical. Their ability to amplify low-level bridge outputs with high accuracy and low noise makes them ideal for industrial automation, structural health monitoring, and biomedical instrumentation. You benefit from their balanced input configuration that minimizes common-mode noise, ensuring reliable and stable signal amplification in demanding environments.

Applications of Instrumentation Amplifiers

Instrumentation amplifiers are widely used in medical devices for precise bio-signal acquisition, such as ECG and EEG, due to their high input impedance and excellent common-mode noise rejection. They play a critical role in industrial process controls and sensor signal conditioning, ensuring accurate and stable measurements under varying environmental conditions. Your choice of an instrumentation amplifier ensures precise amplification of low-level differential signals with minimal interference, making them ideal for applications requiring high accuracy and reliability.

Advantages and Disadvantages of Bridge Amplifiers

Bridge amplifiers offer high sensitivity and excellent common-mode noise rejection, making them ideal for precise sensor signal amplification, especially in strain gauge applications. However, they are typically more complex and expensive than instrumentation amplifiers and may require careful bridge balancing to maintain accuracy. Your choice depends on the specific application requirements, such as measurement precision and environmental noise conditions.

Advantages and Disadvantages of Instrumentation Amplifiers

Instrumentation amplifiers offer high input impedance and excellent common-mode rejection, making them ideal for precise, low-level signal measurements in noisy environments. However, they tend to be more complex and costly compared to bridge amplifiers, requiring careful design and calibration to maintain accuracy. Your choice depends on the need for accuracy versus simplicity and budget constraints in your application.

Performance Comparison: Accuracy, Noise, and Linearity

Instrumentation amplifiers excel in accuracy with high input impedance and precise gain settings, minimizing signal distortion and enhancing measurement reliability. Bridge amplifiers offer robust performance in strain gauge circuits but typically exhibit higher noise levels and lower linearity compared to instrumentation amplifiers. In applications demanding superior noise rejection and linear response, instrumentation amplifiers provide enhanced performance due to their differential input design and optimized common-mode rejection ratio (CMRR).

Choosing Between Bridge Amplifier and Instrumentation Amplifier

Choosing between a bridge amplifier and an instrumentation amplifier depends on the application requirements for precision and noise rejection. Bridge amplifiers excel in measuring signal variations from resistive sensors, like strain gauges, by directly amplifying differential signals with built-in bridge completion. Instrumentation amplifiers offer superior common-mode rejection ratio (CMRR) and input impedance, making them ideal for amplifying low-level signals in noisy environments and ensuring higher accuracy in biomedical and industrial sensor applications.

bridge amplifier vs instrumentation amplifier Infographic

electrown.com

electrown.com