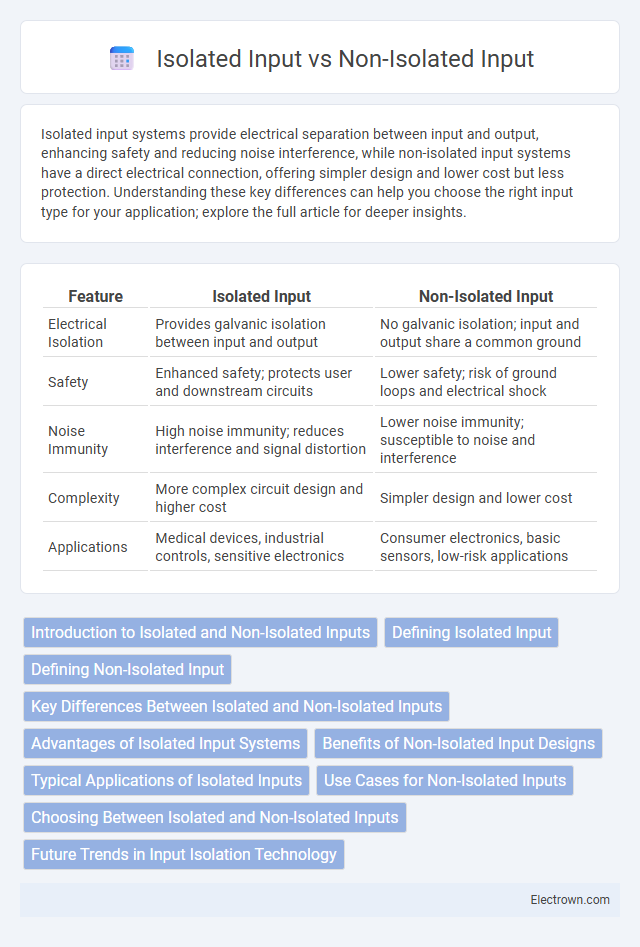

Isolated input systems provide electrical separation between input and output, enhancing safety and reducing noise interference, while non-isolated input systems have a direct electrical connection, offering simpler design and lower cost but less protection. Understanding these key differences can help you choose the right input type for your application; explore the full article for deeper insights.

Table of Comparison

| Feature | Isolated Input | Non-Isolated Input |

|---|---|---|

| Electrical Isolation | Provides galvanic isolation between input and output | No galvanic isolation; input and output share a common ground |

| Safety | Enhanced safety; protects user and downstream circuits | Lower safety; risk of ground loops and electrical shock |

| Noise Immunity | High noise immunity; reduces interference and signal distortion | Lower noise immunity; susceptible to noise and interference |

| Complexity | More complex circuit design and higher cost | Simpler design and lower cost |

| Applications | Medical devices, industrial controls, sensitive electronics | Consumer electronics, basic sensors, low-risk applications |

Introduction to Isolated and Non-Isolated Inputs

Isolated inputs provide electrical separation between the input signal and the output circuit, enhancing safety and reducing noise interference, which is crucial in industrial and medical applications. Non-isolated inputs directly connect the input signal to the system, offering simpler design and lower cost but with increased susceptibility to noise and potential ground loop issues. Understanding these differences helps you choose the right input type to ensure signal integrity and system reliability.

Defining Isolated Input

Isolated input refers to an electrical interface where the input circuit is electrically separated from the output or main circuit, typically using transformers, optocouplers, or isolation amplifiers. This separation protects your system from voltage spikes, ground loops, and noise interference, ensuring signal integrity and safety in sensitive applications. Non-isolated input, by contrast, shares a common reference with the output, making it more susceptible to interference and potential damage in harsh electrical environments.

Defining Non-Isolated Input

Non-isolated input refers to a power supply configuration where the input and output share a common ground or reference point, allowing direct electrical connection between the two. This type of input is commonly used in cost-effective applications where galvanic isolation is not required, providing simpler design and improved efficiency. Your choice of non-isolated input impacts system safety and noise immunity, so understanding its characteristics is essential for appropriate application.

Key Differences Between Isolated and Non-Isolated Inputs

Isolated inputs provide electrical separation between input and output, enhancing safety and reducing noise interference, while non-isolated inputs share a common ground, making them simpler and cost-effective but more susceptible to signal noise and potential ground loops. The key difference lies in their grounding schemes; isolated inputs use transformers or optocouplers to break the ground connection, whereas non-isolated inputs rely on direct electrical connections. Your choice between these depends on the application's sensitivity to noise, safety requirements, and system complexity.

Advantages of Isolated Input Systems

Isolated input systems enhance safety by preventing ground loops and electrical noise from affecting signal integrity, making them ideal for industrial environments with high voltage differentials. They provide superior protection against voltage spikes, reducing damage risks to sensitive control equipment and improving system reliability. The galvanic isolation also enables accurate signal transmission across different ground potentials, ensuring consistent performance and reducing maintenance costs.

Benefits of Non-Isolated Input Designs

Non-isolated input designs offer direct electrical connection between the input and output, resulting in lower component costs and reduced complexity. These designs provide higher efficiency and faster response times due to minimal signal attenuation and simpler circuitry. Non-isolated inputs are ideal for applications requiring compact size and cost-effective solutions without strict galvanic isolation requirements.

Typical Applications of Isolated Inputs

Isolated inputs are commonly used in industrial automation systems to prevent ground loops and protect sensitive controllers from high voltage spikes. They are essential in environments with noisy electrical signals, such as motor control circuits, process control, and power distribution monitoring. Typical applications include PLC input modules, data acquisition systems, and instrumentation where signal integrity and safety are critical.

Use Cases for Non-Isolated Inputs

Non-isolated inputs are ideal for applications where cost efficiency and simplicity are prioritized, such as in low-voltage DC systems or signal-level inputs in industrial automation. Your design benefits from reduced complexity and lower component counts, making non-isolated inputs suitable for environments with minimal noise interference. These inputs efficiently handle direct connections to microcontrollers or PLCs in controlled electrical settings without requiring galvanic separation.

Choosing Between Isolated and Non-Isolated Inputs

Choosing between isolated and non-isolated inputs depends on the application's safety requirements and noise sensitivity. Isolated inputs prevent ground loops and protect sensitive electronics from high-voltage spikes by electrically separating the input signal from the system, making them ideal for industrial environments with heavy electrical noise. Non-isolated inputs offer simpler, cost-effective solutions for low-noise, low-voltage applications where direct electrical connection is acceptable.

Future Trends in Input Isolation Technology

Future trends in input isolation technology emphasize enhanced galvanic isolation methods using advanced materials such as silicon carbide and gallium nitride for higher voltage tolerance and faster switching speeds. Integration of digital isolation with microelectromechanical systems (MEMS) is expected to improve signal integrity and reduce electromagnetic interference in compact designs. Emerging applications in renewable energy systems and electric vehicles drive innovations toward more energy-efficient isolated input modules with intelligent diagnostics and self-healing capabilities.

isolated input vs non-isolated input Infographic

electrown.com

electrown.com