Type K thermocouples, made from nickel-chromium and nickel-alumel, are widely used for their broad temperature range and resistance to oxidation, while Type J thermocouples, composed of iron and constantan, offer better accuracy at lower temperatures but are prone to rust and have a narrower range. Understanding the differences between these thermocouple types will help you select the most suitable sensor for your specific temperature measurement needs--read on to explore their characteristics in detail.

Table of Comparison

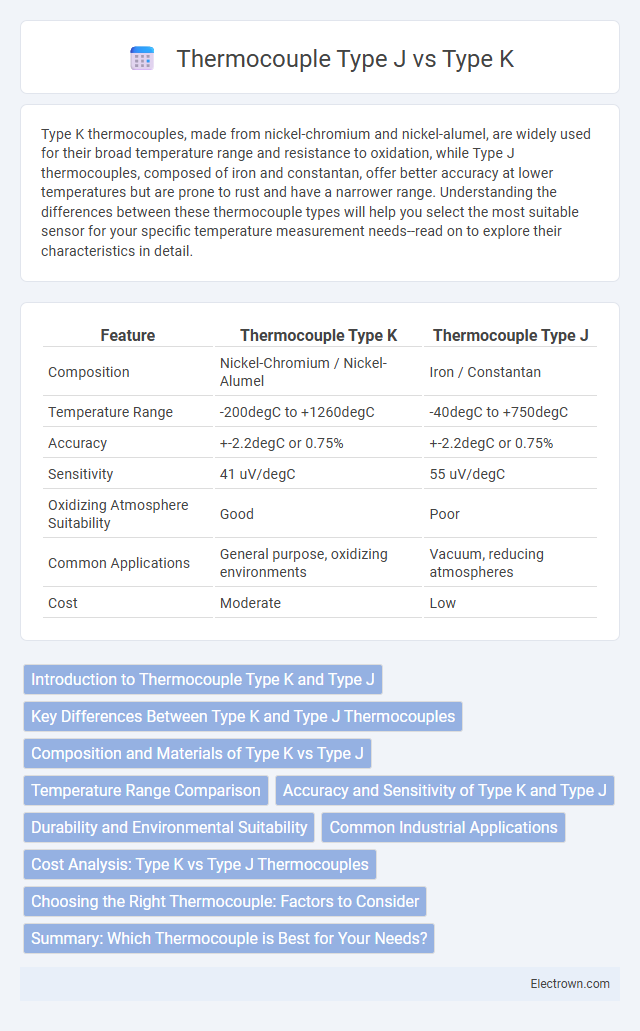

| Feature | Thermocouple Type K | Thermocouple Type J |

|---|---|---|

| Composition | Nickel-Chromium / Nickel-Alumel | Iron / Constantan |

| Temperature Range | -200degC to +1260degC | -40degC to +750degC |

| Accuracy | +-2.2degC or 0.75% | +-2.2degC or 0.75% |

| Sensitivity | 41 uV/degC | 55 uV/degC |

| Oxidizing Atmosphere Suitability | Good | Poor |

| Common Applications | General purpose, oxidizing environments | Vacuum, reducing atmospheres |

| Cost | Moderate | Low |

Introduction to Thermocouple Type K and Type J

Thermocouple Type K, composed of chromel and alumel alloys, offers a wide temperature range from -200degC to 1260degC, making it versatile for various industrial applications. Thermocouple Type J, made from iron and constantan, operates effectively between -40degC and 750degC, providing higher sensitivity at lower temperatures. Understanding these differences helps you select the appropriate thermocouple for accurate temperature measurement in your specific environment.

Key Differences Between Type K and Type J Thermocouples

Type K thermocouples, composed of nickel-chromium and nickel-alumel, operate accurately in a wider temperature range (-200degC to 1260degC) compared to Type J thermocouples, which consist of iron and constantan and function effectively between -40degC and 750degC. You will find that Type K offers better oxidation resistance and higher durability in oxidizing atmospheres, whereas Type J provides better performance in reducing atmospheres but is more prone to corrosion and aging. Both types have distinct voltage output characteristics, with Type K producing approximately 41 uV/degC and Type J around 55 uV/degC, impacting their sensitivity and application suitability.

Composition and Materials of Type K vs Type J

Type K thermocouples consist of chromel (nickel-chromium alloy) as the positive leg and alumel (nickel-aluminum alloy) as the negative leg, offering high oxidation resistance and stability at elevated temperatures. Type J thermocouples use iron as the positive leg and constantan (copper-nickel alloy) as the negative leg, making them suitable for reducing atmospheres but more prone to oxidation. The distinct metallurgical compositions of Type K and Type J thermocouples directly influence their temperature ranges, durability, and application environments.

Temperature Range Comparison

Type K thermocouples operate effectively within a temperature range of approximately -200degC to 1,260degC, making them suitable for high-temperature industrial applications. In contrast, Type J thermocouples function reliably from -40degC to 750degC, offering a narrower but precise range ideal for lower temperature measurements. The broader temperature tolerance of Type K thermocouples provides greater versatility in environments requiring high heat resistance and long-term stability.

Accuracy and Sensitivity of Type K and Type J

Type K thermocouples, composed of chromel and alumel, offer a broad temperature range from -200degC to 1260degC with moderate accuracy typically within +-1.5degC or +-0.4% of reading, making them suitable for general-purpose applications. Type J thermocouples, made of iron and constantan, provide higher accuracy at lower temperatures, generally +-1.0degC or +-0.4%, but have a narrower temperature range from -40degC to 750degC and lower sensitivity compared to Type K. Type K exhibits greater sensitivity with a typical voltage output of about 41 uV/degC versus approximately 55 uV/degC for Type J, influencing precision in dynamic temperature measurement scenarios.

Durability and Environmental Suitability

Type K thermocouples, made from nickel-chromium and nickel-alumel, offer superior durability and resistance to oxidation in high-temperature environments up to 1260degC, making them ideal for harsh industrial conditions. In contrast, Type J thermocouples, composed of iron and constantan, have a lower maximum temperature rating around 760degC and are more prone to rust and corrosion, limiting their use in humid or oxidizing environments. Type K's robust construction suits it for more diverse and challenging environmental applications, while Type J is better suited for controlled, less corrosive settings.

Common Industrial Applications

Type K thermocouples, made from nickel-chromium and nickel-alumel, are widely used in high-temperature industrial environments such as furnaces, kilns, and gas turbine exhausts due to their broad temperature range (-200degC to 1260degC) and durability. Type J thermocouples, composed of iron and constantan, are preferred in lower temperature applications like older machinery and heating systems, operating efficiently up to 760degC. Your choice between Type K and Type J depends on the specific temperature requirements and atmospheric conditions of your industrial process.

Cost Analysis: Type K vs Type J Thermocouples

Type K thermocouples generally cost more than Type J due to their wider temperature range and higher oxidation resistance, making them suitable for high-temperature applications up to 1,260degC. Type J thermocouples, made from iron and constantan, are less expensive but offer a lower maximum temperature limit of about 750degC and are more prone to rust in moist environments. Evaluating the total cost involves considering not only initial material expenses but also lifespan, maintenance frequency, and environmental suitability for precise temperature measurement needs.

Choosing the Right Thermocouple: Factors to Consider

When choosing between Type K and Type J thermocouples, consider factors such as temperature range, environmental conditions, and material compatibility. Type K thermocouples excel in high-temperature environments up to 1,260degC and offer good oxidation resistance, while Type J is better suited for lower temperatures up to 750degC with a more limited range but higher sensitivity. Your selection should prioritize the application's temperature requirements and operational environment to ensure accurate and reliable measurements.

Summary: Which Thermocouple is Best for Your Needs?

Type K thermocouples, made from chromel and alumel, offer wide temperature range suitability from -200degC to 1260degC and excellent resistance to oxidation, making them ideal for high-temperature industrial applications. Type J thermocouples, composed of iron and constantan, are best suited for lower temperature ranges up to 760degC and provide better accuracy in reducing atmospheres. Selecting the best thermocouple depends on your specific temperature range, environmental conditions, and required durability for accurate and reliable measurements.

Thermocouple type K vs Type J Infographic

electrown.com

electrown.com