QFP (Quad Flat Package) offers easy visual inspection and simpler soldering due to its gull-wing leads, while BGA (Ball Grid Array) provides better thermal performance and higher pin density in a more compact footprint. Understanding the differences between these packaging types can help you choose the best option for your electronic design; continue reading to explore their advantages and applications in detail.

Table of Comparison

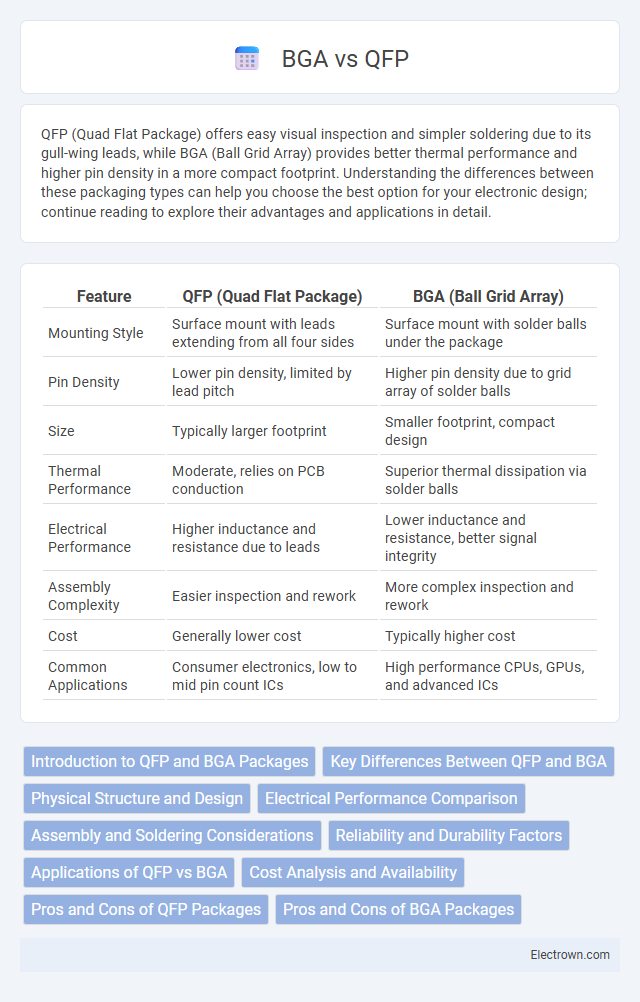

| Feature | QFP (Quad Flat Package) | BGA (Ball Grid Array) |

|---|---|---|

| Mounting Style | Surface mount with leads extending from all four sides | Surface mount with solder balls under the package |

| Pin Density | Lower pin density, limited by lead pitch | Higher pin density due to grid array of solder balls |

| Size | Typically larger footprint | Smaller footprint, compact design |

| Thermal Performance | Moderate, relies on PCB conduction | Superior thermal dissipation via solder balls |

| Electrical Performance | Higher inductance and resistance due to leads | Lower inductance and resistance, better signal integrity |

| Assembly Complexity | Easier inspection and rework | More complex inspection and rework |

| Cost | Generally lower cost | Typically higher cost |

| Common Applications | Consumer electronics, low to mid pin count ICs | High performance CPUs, GPUs, and advanced ICs |

Introduction to QFP and BGA Packages

QFP (Quad Flat Package) and BGA (Ball Grid Array) are popular surface-mount packaging types used in electronic components. QFP features gull-wing leads extending from all four sides, ideal for fine-pitch applications and easy visual inspection during assembly. BGA packages utilize an array of solder balls on the underside, providing better thermal performance and electrical conductivity for high-density circuits, which can enhance your device's reliability and performance.

Key Differences Between QFP and BGA

QFP (Quad Flat Package) features gull-wing leads extending from all four sides, allowing easier visual inspection and soldering on PCB surfaces, whereas BGA (Ball Grid Array) uses solder balls beneath the package, providing higher pin density and superior thermal and electrical performance. QFP packages are typically thinner but have limitations in pin count and may suffer from lead damage during handling, while BGA packages support more connections in a smaller footprint and offer improved signal integrity for high-frequency applications. The choice between QFP and BGA depends on board complexity, manufacturing capabilities, and performance requirements, with BGAs favored for advanced, compact, high-speed systems.

Physical Structure and Design

QFP (Quad Flat Package) features gull-wing leads extending from all four sides, allowing easy soldering on PCB surfaces with visible pins, while BGA (Ball Grid Array) utilizes an array of solder balls underneath the package for more compact and robust connections. The physical structure of QFP provides good inspection access due to its exposed leads, but BGA's design minimizes signal interference and supports higher pin counts within a smaller footprint. Your choice between QFP and BGA should consider layout density requirements and thermal performance tied to their distinct structural designs.

Electrical Performance Comparison

QFP (Quad Flat Package) offers moderate electrical performance suited for lower frequency applications due to longer lead lengths causing higher inductance and signal delay. BGA (Ball Grid Array) provides superior electrical performance with shorter interconnects and reduced parasitic inductance, enhancing signal integrity and power distribution in high-frequency circuits. Your choice impacts signal integrity, with BGA preferred for advanced, high-speed electronic designs.

Assembly and Soldering Considerations

QFP (Quad Flat Package) requires precise alignment during assembly due to its gull-wing leads, making manual soldering more complex and susceptible to bridging, whereas BGA (Ball Grid Array) uses solder balls beneath the package, demanding specialized reflow soldering and X-ray inspection for joint verification. Thermal profiles for BGA must be carefully controlled to ensure solder ball melting without damaging the package, while QFP soldering can tolerate conventional wave or hand soldering techniques. BGA offers improved electrical performance and reliability in high-density applications but necessitates more advanced assembly equipment compared to the relatively straightforward process for QFP.

Reliability and Durability Factors

QFP (Quad Flat Package) exhibits moderate reliability but is more prone to solder joint fatigue and damage due to its exposed leads, especially in high-vibration environments. BGA (Ball Grid Array) offers superior durability with its solder balls providing better mechanical strength, enhanced thermal conductivity, and resistance to thermal cycling stress. The reduced lead length in BGA minimizes electrical failures, improving long-term reliability in demanding applications.

Applications of QFP vs BGA

QFP (Quad Flat Package) is commonly used in applications requiring easy visual inspection and manual soldering, such as consumer electronics, automotive control systems, and low to medium pin count microcontrollers. BGA (Ball Grid Array) excels in high-performance computing, smartphones, and advanced communication devices due to its superior thermal resistance and electrical performance. Your choice between QFP and BGA depends on your specific application's requirements for assembly complexity, heat dissipation, and space constraints.

Cost Analysis and Availability

QFP (Quad Flat Package) generally offers lower manufacturing costs due to simpler assembly and widespread supply, making it more accessible for low to mid-volume production. BGA (Ball Grid Array) tends to have higher initial costs because of advanced packaging technology and specialized equipment requirements but benefits from improved performance and miniaturization. Availability of QFP components remains robust across various vendors, while BGA may face limited options and longer lead times depending on component specifications.

Pros and Cons of QFP Packages

QFP (Quad Flat Package) offers easy inspection and soldering due to its gull-wing leads, making it suitable for prototypes and low to medium complexity circuits. However, QFP packages can face limitations in pin density and are more prone to lead damage compared to BGA (Ball Grid Array) packages. Your choice depends on balancing assembly cost and performance requirements, as QFPs typically provide lower cost but less reliable connections than BGAs.

Pros and Cons of BGA Packages

Ball Grid Array (BGA) packages offer superior thermal performance and electrical conductivity due to their increased contact points and compact design, making them ideal for high-density circuit boards and advanced microprocessors. However, BGA components can be challenging for rework and inspection because their solder joints are located underneath the package, complicating fault detection and repair. You should consider these trade-offs when selecting between BGA and QFP for your electronic assembly, balancing performance benefits against manufacturing complexity.

QFP vs BGA Infographic

electrown.com

electrown.com