Poly gate transistors use polysilicon as the gate material, offering good compatibility with silicon dioxide but facing limitations in performance due to higher gate resistance and electron mobility issues. Metal gate technology enhances transistor speed and reduces power consumption by replacing polysilicon with metals that provide lower resistance and improved threshold voltage control; explore the rest of this article to understand how these differences impact your device's efficiency.

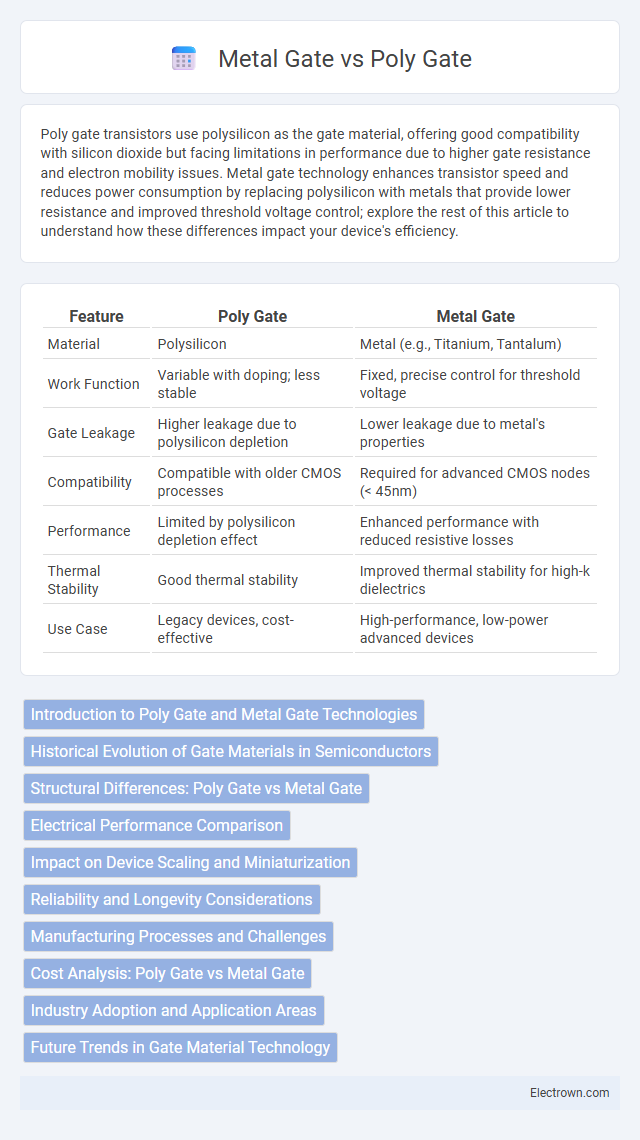

Table of Comparison

| Feature | Poly Gate | Metal Gate |

|---|---|---|

| Material | Polysilicon | Metal (e.g., Titanium, Tantalum) |

| Work Function | Variable with doping; less stable | Fixed, precise control for threshold voltage |

| Gate Leakage | Higher leakage due to polysilicon depletion | Lower leakage due to metal's properties |

| Compatibility | Compatible with older CMOS processes | Required for advanced CMOS nodes (< 45nm) |

| Performance | Limited by polysilicon depletion effect | Enhanced performance with reduced resistive losses |

| Thermal Stability | Good thermal stability | Improved thermal stability for high-k dielectrics |

| Use Case | Legacy devices, cost-effective | High-performance, low-power advanced devices |

Introduction to Poly Gate and Metal Gate Technologies

Poly gate technology utilizes polysilicon as the gate electrode material in MOSFET devices, providing compatibility with high-temperature processes but suffering from increased gate depletion effects and resistance. Metal gate technology replaces polysilicon with conductive metals like titanium nitride or tantalum, enhancing gate conductivity, reducing depletion effects, and enabling better control over threshold voltage. The transition from poly gate to metal gate technologies marks a critical advancement in semiconductor fabrication, improving device performance and scaling in modern integrated circuits.

Historical Evolution of Gate Materials in Semiconductors

The historical evolution of gate materials in semiconductors transitioned from polysilicon gates to metal gates to address dual challenges of gate depletion and threshold voltage instability. Polysilicon gates, dominant since the 1970s, offered compatibility with silicon dioxide but suffered from dopant diffusion and increased resistance at nanometer scales. Metal gates re-emerged in the 2000s alongside high-k dielectrics, enabling improved performance, reduced leakage, and scalability in advanced CMOS technologies such as Intel's 45nm and beyond nodes.

Structural Differences: Poly Gate vs Metal Gate

Poly Gate technology features a conductive polysilicon layer as the gate electrode, which forms a gate oxide interface prone to higher resistance and polysilicon depletion effects. Metal Gate technology replaces the polysilicon gate with a metal electrode, significantly reducing gate resistance and eliminating depletion, thereby enhancing device performance and scalability. The structural shift from polycrystalline silicon to metal gates also enables the integration of high-k dielectrics, improving gate capacitance and reducing leakage currents in advanced semiconductor devices.

Electrical Performance Comparison

Metal gates exhibit superior electrical performance compared to poly gates, offering lower resistance and better control over gate depletion, which enhances transistor switching speed and reduces power consumption. Poly gates often suffer from higher gate-to-channel leakage and slower response times due to polysilicon depletion effects. Evaluating your design requirements, choosing metal gates can significantly improve device reliability and efficiency in advanced semiconductor technologies.

Impact on Device Scaling and Miniaturization

Metal gate technology significantly improves device scaling and miniaturization by reducing gate leakage and providing better electrostatic control compared to poly gate materials. High-k dielectric integration with metal gates enables further shrinkage of transistor dimensions without compromising performance or increasing power consumption. This advancement accelerates the development of smaller, faster, and more energy-efficient semiconductor devices in advanced technology nodes.

Reliability and Longevity Considerations

Metal gates demonstrate superior reliability and longevity compared to poly gates due to their enhanced resistance to electromigration and lower gate leakage currents, which contribute to stable device performance over extended periods. Poly gates, prone to depletion effects and higher resistance, may experience increased threshold voltage shifts and reduced lifespan in high-performance applications. When selecting a gate material for your semiconductor device, metal gates offer robust durability essential for long-term operational stability.

Manufacturing Processes and Challenges

Poly gate transistors utilize polysilicon as the gate material, which simplifies manufacturing due to well-established deposition and patterning techniques but faces challenges like polysilicon depletion and gate resistance impacting device performance. Metal gate processes involve depositing metals via atomic layer deposition or sputtering, offering lower resistivity and eliminating depletion effects, though integrating high-k dielectrics and preventing metal gate diffusion present significant fabrication complexities. Scaling metal gate technology demands precise control over work function tuning and thermal budgets to maintain device reliability and performance in advanced CMOS nodes.

Cost Analysis: Poly Gate vs Metal Gate

Poly gate technology offers a lower manufacturing cost due to established fabrication processes and cheaper raw materials like polysilicon. Metal gate integration involves higher expenses driven by complex deposition techniques, advanced materials like tantalum or titanium nitride, and additional process steps for work function tuning. Cost benefits of poly gates diminish in advanced nodes where metal gates provide better performance and yield, offsetting their higher initial investment.

Industry Adoption and Application Areas

Metal gate technology has largely replaced poly gate in advanced semiconductor manufacturing due to its superior electrical performance and scalability in sub-45nm nodes. Major semiconductor fabs, including Intel, TSMC, and Samsung, adopt metal gates extensively in high-performance CPUs, GPUs, and memory devices to reduce gate leakage and improve transistor speed. Poly gates remain prevalent in legacy processes and cost-sensitive applications such as analog circuits and microcontrollers where scaling demands are less stringent.

Future Trends in Gate Material Technology

Metal gate technology is rapidly advancing due to its superior electrical conductivity and reduced power leakage, making it the preferred choice for next-generation semiconductor devices. Emerging materials such as high-k dielectrics combined with metal gates are enhancing transistor performance and scaling capabilities beyond traditional poly gate limitations. Industry trends emphasize integration of novel metal alloys and 2D materials like graphene to further improve gate control and energy efficiency in future node developments.

Poly Gate vs Metal Gate Infographic

electrown.com

electrown.com