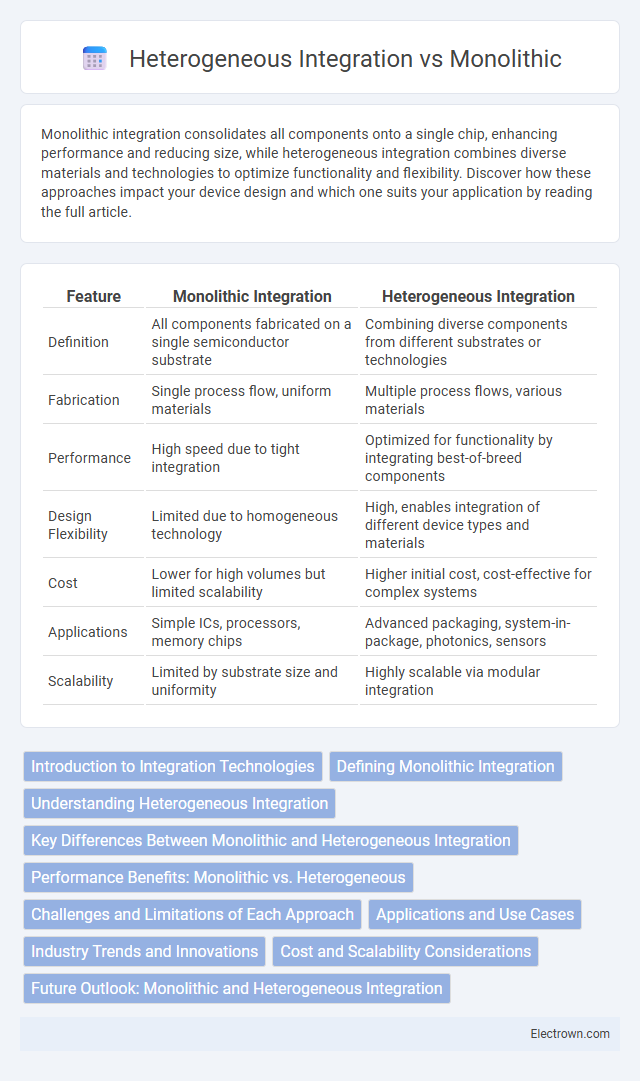

Monolithic integration consolidates all components onto a single chip, enhancing performance and reducing size, while heterogeneous integration combines diverse materials and technologies to optimize functionality and flexibility. Discover how these approaches impact your device design and which one suits your application by reading the full article.

Table of Comparison

| Feature | Monolithic Integration | Heterogeneous Integration |

|---|---|---|

| Definition | All components fabricated on a single semiconductor substrate | Combining diverse components from different substrates or technologies |

| Fabrication | Single process flow, uniform materials | Multiple process flows, various materials |

| Performance | High speed due to tight integration | Optimized for functionality by integrating best-of-breed components |

| Design Flexibility | Limited due to homogeneous technology | High, enables integration of different device types and materials |

| Cost | Lower for high volumes but limited scalability | Higher initial cost, cost-effective for complex systems |

| Applications | Simple ICs, processors, memory chips | Advanced packaging, system-in-package, photonics, sensors |

| Scalability | Limited by substrate size and uniformity | Highly scalable via modular integration |

Introduction to Integration Technologies

Monolithic integration consolidates all components onto a single chip, enhancing performance and reducing parasitics in semiconductor devices. Heterogeneous integration combines various chips and materials using advanced packaging techniques, enabling diverse functionalities and improved system flexibility. Your choice between these integration technologies depends on the desired balance of scalability, cost, and performance for applications in electronics and photonics.

Defining Monolithic Integration

Monolithic integration refers to the process of fabricating all electronic components and functions within a single semiconductor substrate, enhancing performance by minimizing interconnect lengths and parasitic losses. This integration method enables higher circuit density and improved reliability due to its unified manufacturing approach. Your choice of monolithic integration can optimize device speed and reduce power consumption in complex integrated circuits.

Understanding Heterogeneous Integration

Heterogeneous integration combines different types of materials and components, such as sensors, processors, and memory, into a single package to enhance performance and functionality. This approach enables the integration of disparate technologies like silicon chips, photonics, and MEMS, overcoming the limitations of monolithic integration, which relies on a single substrate. By leveraging advanced packaging techniques like 3D stacking and chiplets, heterogeneous integration achieves higher density, improved power efficiency, and greater design flexibility for applications in AI, 5G, and IoT devices.

Key Differences Between Monolithic and Heterogeneous Integration

Monolithic integration involves fabricating all components of a system on a single semiconductor substrate, resulting in superior performance and lower parasitics due to close proximity of elements. Heterogeneous integration combines multiple chips or materials with different properties into one package, enabling diverse functionalities and improved customization but with increased design complexity. Your choice depends on trade-offs between performance, design flexibility, and manufacturing scalability in applications like RF systems or advanced computing.

Performance Benefits: Monolithic vs. Heterogeneous

Monolithic integration offers superior performance benefits due to its seamless electrical connections and minimal signal loss, enabling faster data transfer and reduced latency. Heterogeneous integration, while providing flexibility by combining diverse materials and components, may introduce interconnect overhead and signal integrity challenges that can impact overall speed. Your choice depends on whether maximum performance or design versatility is the priority for your application.

Challenges and Limitations of Each Approach

Monolithic integration faces challenges such as limited design flexibility and higher fabrication complexity, often resulting in increased manufacturing costs and reduced yield rates due to defects in a single substrate. Heterogeneous integration encounters limitations in thermal management, interconnect density, and packaging complexity, making it difficult to achieve seamless communication between diverse materials and components. Both approaches struggle with trade-offs between performance, scalability, and cost-effectiveness in advanced semiconductor applications.

Applications and Use Cases

Monolithic integration excels in high-performance computing applications like microprocessors and memory chips where uniformity and minimal interconnect delays are critical. Heterogeneous integration suits advanced systems such as AI accelerators, sensors, and 5G modules, combining diverse components like CMOS, photonics, and MEMS for multifunctional devices. Use cases in automotive, IoT, and healthcare benefit from heterogeneous integration by enabling compact, power-efficient, and high-functionality solutions.

Industry Trends and Innovations

Industry trends indicate a growing shift towards heterogeneous integration as semiconductor manufacturers aim to combine diverse materials and advanced packaging techniques to overcome the physical limits of monolithic scaling. Innovations such as chiplet architectures, 3D stacking, and advanced interconnects enable improved performance, power efficiency, and design flexibility in heterogeneous systems. Monolithic integration remains relevant for applications requiring high-density integration and lower latency but faces challenges in cost and scalability compared to the modular benefits of heterogeneous solutions.

Cost and Scalability Considerations

Monolithic integration offers lower initial costs due to a unified manufacturing process but faces scalability limitations as design complexity and chip size increase, leading to higher defect rates and yield loss. Heterogeneous integration incurs higher upfront costs with advanced packaging and assembly techniques but provides superior scalability by allowing the combination of diverse technologies and processes on a single platform. Cost efficiency in heterogeneous integration improves over time through modular upgrades and better yield management, making it suitable for high-performance applications demanding flexibility and growth.

Future Outlook: Monolithic and Heterogeneous Integration

Monolithic integration offers promising advancements in power efficiency and scaling for future semiconductor devices, leveraging unified fabrication processes to enhance performance and reduce cost. Heterogeneous integration drives innovation through the combination of diverse materials and technologies, enabling customized solutions that address specific application needs such as AI, 5G, and IoT. The convergence of these approaches is expected to shape the semiconductor landscape, with monolithic integration excelling in high-density logic and heterogeneous integration advancing system-level complexity and multifunctionality.

Monolithic vs Heterogeneous Integration Infographic

electrown.com

electrown.com