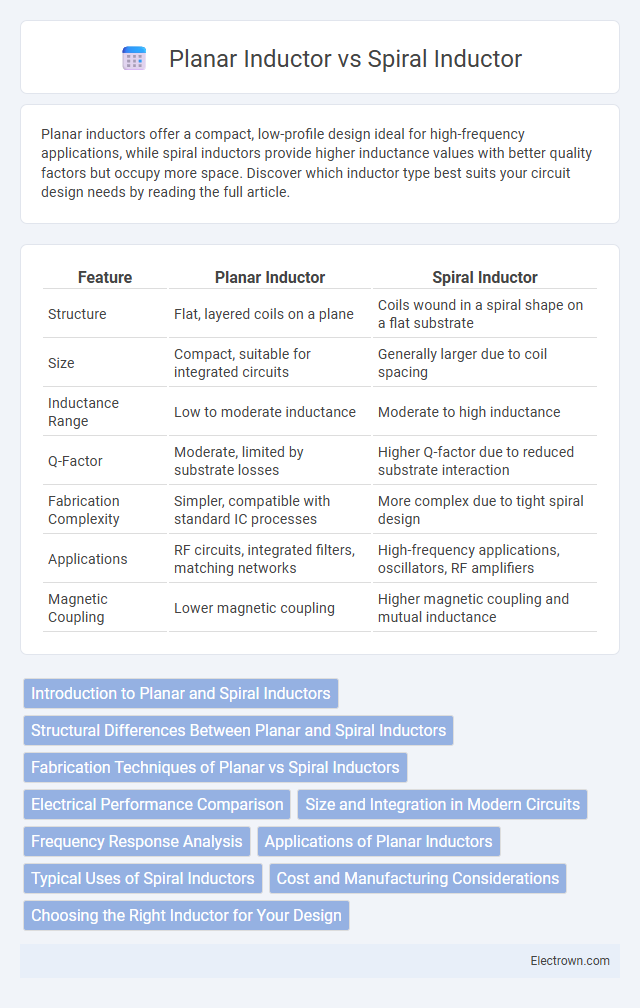

Planar inductors offer a compact, low-profile design ideal for high-frequency applications, while spiral inductors provide higher inductance values with better quality factors but occupy more space. Discover which inductor type best suits your circuit design needs by reading the full article.

Table of Comparison

| Feature | Planar Inductor | Spiral Inductor |

|---|---|---|

| Structure | Flat, layered coils on a plane | Coils wound in a spiral shape on a flat substrate |

| Size | Compact, suitable for integrated circuits | Generally larger due to coil spacing |

| Inductance Range | Low to moderate inductance | Moderate to high inductance |

| Q-Factor | Moderate, limited by substrate losses | Higher Q-factor due to reduced substrate interaction |

| Fabrication Complexity | Simpler, compatible with standard IC processes | More complex due to tight spiral design |

| Applications | RF circuits, integrated filters, matching networks | High-frequency applications, oscillators, RF amplifiers |

| Magnetic Coupling | Lower magnetic coupling | Higher magnetic coupling and mutual inductance |

Introduction to Planar and Spiral Inductors

Planar inductors are fabricated using thin conductive layers on a substrate, offering compact size and efficient integration in RF and microwave circuits. Spiral inductors consist of multiple turns of conductive material arranged in a spiral pattern, providing higher inductance values and improved quality factors for on-chip applications. Both planar and spiral inductors are essential components in integrated circuit design, with distinct advantages based on fabrication methods and performance requirements.

Structural Differences Between Planar and Spiral Inductors

Planar inductors feature flat, multi-layered designs fabricated using thin-film or PCB technologies, enabling compact, low-profile structures ideal for high-frequency applications. Spiral inductors consist of concentric loops of wire etched or wound in a spiral pattern, offering simplicity in fabrication but typically occupying more surface area. Your choice depends on the desired inductance, frequency response, and space constraints, where planar inductors excel in integration and spiral inductors provide straightforward manufacturing.

Fabrication Techniques of Planar vs Spiral Inductors

Planar inductors are typically fabricated using photolithography and thin-film deposition on a flat substrate, allowing for precise patterning and integration with other IC components. Spiral inductors, often created using similar lithographic processes, involve winding metal traces in a spiral shape on the semiconductor surface, which can lead to greater inductance density but more complex parasitic effects. Your choice between planar and spiral inductors depends on the specific fabrication capabilities, desired inductance values, and integration requirements in your RF or microwave circuit design.

Electrical Performance Comparison

Planar inductors typically offer lower parasitic capacitance and better high-frequency performance compared to spiral inductors, making them suitable for high-frequency RF applications. Spiral inductors exhibit higher inductance density but often suffer from increased resistive losses and lower quality factors (Q-factor) due to longer current paths and mutual inductance effects. Your choice depends on the required balance between inductance value, quality factor, and operating frequency in your circuit design.

Size and Integration in Modern Circuits

Planar inductors offer a compact footprint and seamless integration with standard CMOS processes, making them ideal for high-density modern circuits. Spiral inductors, while providing higher inductance values per unit area, tend to occupy more surface area and face challenges in miniaturization. The choice between planar and spiral inductors depends heavily on size constraints and integration requirements in RF and analog circuit design.

Frequency Response Analysis

Planar inductors exhibit a stable frequency response with low parasitic capacitance, making them ideal for high-frequency applications up to several GHz. Spiral inductors offer higher inductance values but suffer from increased parasitic effects, leading to diminished performance at elevated frequencies. Your choice between planar and spiral inductors should consider the operational frequency range and the impact of parasitic elements on signal integrity.

Applications of Planar Inductors

Planar inductors are widely used in RF circuits, power management systems, and integrated passive devices due to their compact size and compatibility with standard semiconductor fabrication processes. Their low profile and ease of integration on printed circuit boards make them ideal for applications requiring high-frequency operation and miniaturization, such as wireless communication modules and GPS devices. In contrast to spiral inductors, planar inductors offer better performance in power electronics where efficient heat dissipation and high current handling are critical.

Typical Uses of Spiral Inductors

Spiral inductors are commonly used in RF circuits, such as filters, oscillators, and tuners, due to their compact size and high-quality factors at high frequencies. Their planar structure allows for easy integration into semiconductor chips, making them ideal for CMOS and RFIC applications. Your designs benefit from spiral inductors when space constraints and performance at microwave frequencies are critical.

Cost and Manufacturing Considerations

Planar inductors offer lower manufacturing costs due to their compatibility with standard PCB fabrication processes and ease of integration in compact designs. Spiral inductors, while providing higher inductance values, often require more complex fabrication techniques that increase production expenses. Cost efficiency in planar inductors makes them ideal for high-volume applications where manufacturing scalability is crucial.

Choosing the Right Inductor for Your Design

Choosing the right inductor for your design involves understanding the distinct characteristics of planar and spiral inductors. Planar inductors offer higher inductance per unit area and better thermal management, making them ideal for compact, high-frequency applications, while spiral inductors provide simpler fabrication and are suited for low-frequency circuits with moderate inductance requirements. Consider your circuit's frequency, size constraints, and power handling needs to determine which inductor type optimizes performance and efficiency for your specific design.

Planar Inductor vs Spiral Inductor Infographic

electrown.com

electrown.com