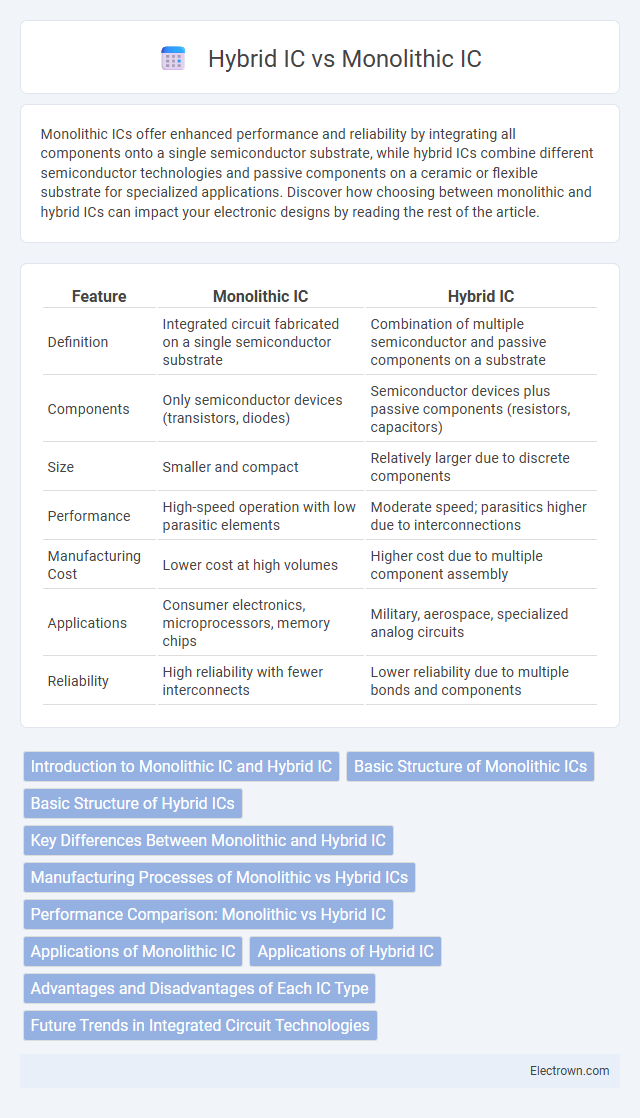

Monolithic ICs offer enhanced performance and reliability by integrating all components onto a single semiconductor substrate, while hybrid ICs combine different semiconductor technologies and passive components on a ceramic or flexible substrate for specialized applications. Discover how choosing between monolithic and hybrid ICs can impact your electronic designs by reading the rest of the article.

Table of Comparison

| Feature | Monolithic IC | Hybrid IC |

|---|---|---|

| Definition | Integrated circuit fabricated on a single semiconductor substrate | Combination of multiple semiconductor and passive components on a substrate |

| Components | Only semiconductor devices (transistors, diodes) | Semiconductor devices plus passive components (resistors, capacitors) |

| Size | Smaller and compact | Relatively larger due to discrete components |

| Performance | High-speed operation with low parasitic elements | Moderate speed; parasitics higher due to interconnections |

| Manufacturing Cost | Lower cost at high volumes | Higher cost due to multiple component assembly |

| Applications | Consumer electronics, microprocessors, memory chips | Military, aerospace, specialized analog circuits |

| Reliability | High reliability with fewer interconnects | Lower reliability due to multiple bonds and components |

Introduction to Monolithic IC and Hybrid IC

Monolithic ICs integrate all components on a single semiconductor substrate, providing compact size, improved performance, and cost efficiency in mass production. Hybrid ICs combine multiple discrete components and substrates within a single package, offering greater flexibility and customization for specialized applications. Understanding the differences helps you select the right IC type tailored to your electronic design needs.

Basic Structure of Monolithic ICs

Monolithic ICs feature a single semiconductor substrate where all circuit components, such as transistors, resistors, and capacitors, are fabricated simultaneously using photolithography and diffusion processes. This uniform structure results in compact, reliable, and cost-effective integrated circuits with high component density. Understanding the basic structure of monolithic ICs helps you appreciate their advantages in performance and integration compared to hybrid ICs, which combine discrete components on a substrate.

Basic Structure of Hybrid ICs

Hybrid ICs consist of multiple discrete components such as resistors, capacitors, and transistors mounted on a ceramic or glass substrate, interconnected through thin film or thick film processes. This basic structure enables customized functionality by integrating different material layers and components within a single module, offering improved performance and flexibility compared to monolithic ICs. The combination of semiconducting chips and passive elements provides enhanced thermal management and higher power handling capabilities in hybrid IC designs.

Key Differences Between Monolithic and Hybrid IC

Monolithic ICs are fabricated entirely on a single semiconductor substrate, enabling higher integration density and faster signal processing compared to Hybrid ICs, which combine multiple discrete components mounted on a ceramic or organic substrate. Hybrid ICs offer greater flexibility in component selection and ease of repair but tend to be bulkier and less cost-effective for high-volume production. Your choice between these IC types depends on requirements for size, performance, and customization in electronic design.

Manufacturing Processes of Monolithic vs Hybrid ICs

Monolithic ICs are manufactured using photolithography to create multiple components on a single semiconductor substrate, resulting in high integration and uniformity. Hybrid ICs combine separate components like chips, resistors, and capacitors mounted on a ceramic or organic substrate, allowing flexibility in component selection but increasing complexity in assembly. Your choice between monolithic and hybrid ICs impacts cost, performance, and production scalability due to these distinct manufacturing processes.

Performance Comparison: Monolithic vs Hybrid IC

Monolithic ICs offer higher performance with faster signal processing and lower parasitic capacitance, making them ideal for high-frequency applications. Hybrid ICs provide greater design flexibility and can integrate diverse components, but often exhibit higher losses and reduced speed compared to monolithic ICs. The performance gap is more pronounced in RF and microwave circuits, where monolithic ICs outperform hybrids in noise figure and power efficiency.

Applications of Monolithic IC

Monolithic ICs are widely used in consumer electronics, automotive systems, and communication devices due to their compact size, reliability, and cost-effectiveness. Your smartphone, digital cameras, and audio amplifiers benefit from monolithic ICs because they integrate multiple functions onto a single semiconductor chip. These integrated circuits excel in high-volume manufacturing environments where consistent performance and small form factors are critical.

Applications of Hybrid IC

Hybrid ICs are widely used in aerospace systems, medical devices, and military equipment due to their ability to integrate different components like resistors, capacitors, and semiconductors on a single substrate, enabling high reliability and performance under harsh conditions. They are essential in RF circuits, microwave devices, and sensor interfaces where monolithic ICs may fall short in customization and operating frequency range. Hybrid IC applications benefit from flexible component combinations, enhancing functionality in communication systems, instrumentation, and power management modules.

Advantages and Disadvantages of Each IC Type

Monolithic ICs offer high reliability, low cost, and compact size due to their integration on a single semiconductor substrate, but they are limited in complexity and often less flexible for mixed-signal applications. Hybrid ICs combine multiple semiconductor materials and components, providing greater design flexibility and superior performance in specialized functions, yet they tend to be larger, more expensive, and less suitable for high-volume production. Your choice depends on needing either cost-effective mass production and miniaturization (monolithic) or customized, high-performance circuitry (hybrid).

Future Trends in Integrated Circuit Technologies

Monolithic ICs, fabricated on a single semiconductor substrate, continue to dominate due to their cost-effectiveness and miniaturization potential, while hybrid ICs offer flexibility by integrating multiple substrates and components for specialized applications. Future trends emphasize advanced monolithic ICs featuring 3D stacking and novel materials like silicon carbide to enhance performance and energy efficiency, whereas hybrid ICs may evolve with embedded passive elements and improved thermal management to support high-frequency and high-power systems. Understanding these innovations can help you anticipate the best integrated circuit technology suited for cutting-edge electronics and emerging industries.

Monolithic IC vs Hybrid IC Infographic

electrown.com

electrown.com