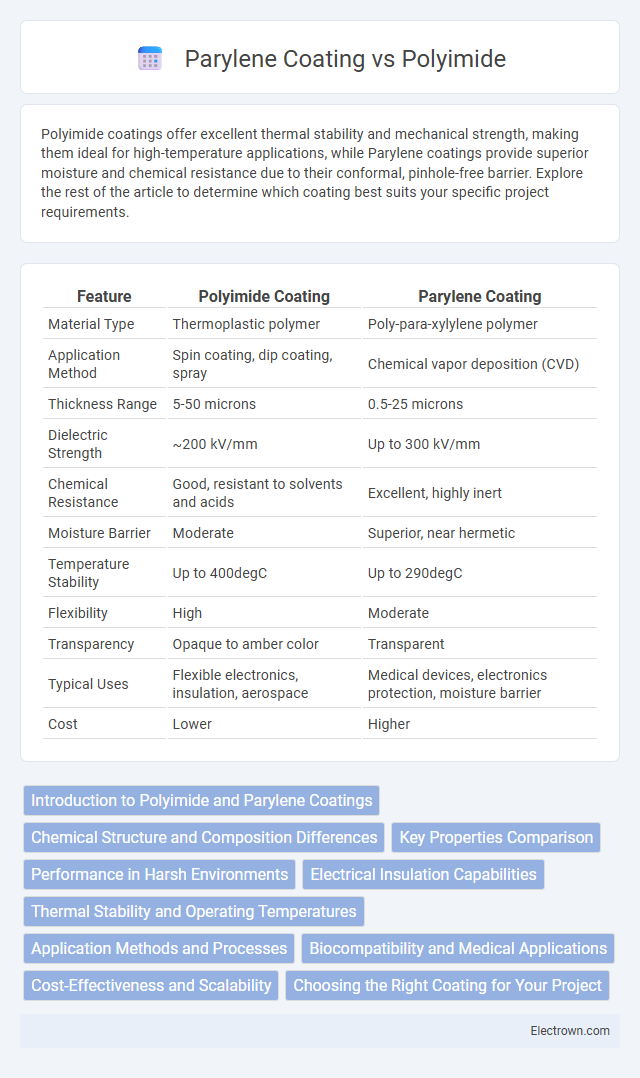

Polyimide coatings offer excellent thermal stability and mechanical strength, making them ideal for high-temperature applications, while Parylene coatings provide superior moisture and chemical resistance due to their conformal, pinhole-free barrier. Explore the rest of the article to determine which coating best suits your specific project requirements.

Table of Comparison

| Feature | Polyimide Coating | Parylene Coating |

|---|---|---|

| Material Type | Thermoplastic polymer | Poly-para-xylylene polymer |

| Application Method | Spin coating, dip coating, spray | Chemical vapor deposition (CVD) |

| Thickness Range | 5-50 microns | 0.5-25 microns |

| Dielectric Strength | ~200 kV/mm | Up to 300 kV/mm |

| Chemical Resistance | Good, resistant to solvents and acids | Excellent, highly inert |

| Moisture Barrier | Moderate | Superior, near hermetic |

| Temperature Stability | Up to 400degC | Up to 290degC |

| Flexibility | High | Moderate |

| Transparency | Opaque to amber color | Transparent |

| Typical Uses | Flexible electronics, insulation, aerospace | Medical devices, electronics protection, moisture barrier |

| Cost | Lower | Higher |

Introduction to Polyimide and Parylene Coatings

Polyimide and Parylene coatings serve distinct functions in protecting electronic components and devices from harsh environments. Polyimide coatings offer excellent thermal stability and mechanical strength, making them ideal for high-temperature applications. Parylene coatings provide a uniform, pinhole-free barrier that excels in moisture and chemical resistance, ensuring your sensitive electronics remain safe under extreme conditions.

Chemical Structure and Composition Differences

Polyimide coatings consist of aromatic polyimide chains characterized by imide linkages formed through the condensation of dianhydrides and diamines, resulting in a high thermal stability and chemical resistance. Parylene coatings are composed of para-xylylene polymers deposited via chemical vapor deposition, featuring a linear hydrocarbon backbone with repeating methylene and aromatic groups that create a conformal, pinhole-free barrier. The key distinction lies in polyimide's heterocyclic imide groups versus parylene's hydrocarbon skeleton, influencing their mechanical flexibility, dielectric properties, and environmental durability.

Key Properties Comparison

Polyimide coatings exhibit exceptional thermal stability with operating temperatures up to 400degC, high mechanical strength, and excellent chemical resistance, making them suitable for demanding electronic and aerospace applications. Parylene coatings offer superior conformality, ultra-thin and pinhole-free coverage, outstanding moisture barrier properties, and excellent electrical insulation, ideal for medical devices and electronics protection. While polyimide provides robust durability under mechanical stress, parylene excels in creating uniform, biocompatible coatings with precise thickness control at the micron and sub-micron levels.

Performance in Harsh Environments

Polyimide coatings offer excellent thermal stability, chemical resistance, and mechanical strength, making them ideal for applications in extreme temperature and corrosive environments. Parylene coatings provide superior moisture and dielectric barrier properties with conformal coverage, ensuring protection against moisture, solvents, and gases in harsh settings. Your choice depends on the specific environmental stressors and required durability for long-term protection.

Electrical Insulation Capabilities

Polyimide coatings offer excellent electrical insulation with high dielectric strength and thermal stability, making them suitable for harsh environments in electronics and aerospace applications. Parylene coatings provide superior conformal insulation with uniform thickness and exceptional moisture and chemical resistance, ideal for protecting sensitive electronic components. Your choice depends on the specific electrical insulation requirements, environmental exposure, and application complexity.

Thermal Stability and Operating Temperatures

Polyimide coatings exhibit excellent thermal stability with operating temperatures typically ranging from -269degC to 400degC, making them ideal for high-temperature electronic and aerospace applications. Parylene coatings provide moderate thermal resistance, with stable performance up to approximately 120degC to 150degC, suitable for biomedical and conformal coating uses. The superior high-temperature endurance of polyimide makes it more suitable for environments requiring prolonged exposure to extreme heat.

Application Methods and Processes

Polyimide coatings are commonly applied using spin coating, dip coating, or spray coating techniques, followed by a high-temperature curing process that ensures thermal stability and chemical resistance. Parylene coatings utilize a vapor deposition polymerization method in a vacuum chamber, producing conformal, pinhole-free films ideal for complex geometries. The distinct application methods influence the coating's uniformity, adhesion, and protective properties, making polyimide suitable for high-temperature electronics and parylene optimal for moisture and chemical barrier applications.

Biocompatibility and Medical Applications

Polyimide and Parylene coatings both offer excellent biocompatibility, but Parylene is often preferred in medical applications due to its superior chemical inertness and impermeability, providing robust protection against moisture and bodily fluids. Polyimide excels in flexibility and thermal stability, making it suitable for implantable devices that require durability under mechanical stress. Your choice depends on the specific medical device requirements, balancing biostability with environmental resistance.

Cost-Effectiveness and Scalability

Polyimide coating offers superior cost-effectiveness due to its lower material and processing expenses, making it ideal for large-scale manufacturing. Parylene coating presents challenges in scalability because of its vapor deposition process, which is more time-consuming and costly for high-volume production. Your choice between polyimide and parylene should consider the trade-off between cost efficiency and the specific application requirements for scalable coating solutions.

Choosing the Right Coating for Your Project

Polyimide coatings offer excellent thermal stability and mechanical strength, making them ideal for high-temperature applications and flexible electronics. Parylene coatings provide superior moisture and chemical resistance with a thin, uniform conformal layer, perfect for protecting intricate components in medical and aerospace devices. Selecting the right coating depends on your project's environmental exposure, mechanical stress, and required dielectric properties to ensure optimal performance and durability.

Polyimide vs Parylene Coating Infographic

electrown.com

electrown.com