Nanoscale inverters leverage quantum effects and reduced dimensions to achieve faster switching speeds and lower power consumption compared to traditional CMOS inverters, which rely on bulk semiconductor materials. Explore the rest of this article to understand how these differences impact your choice for next-generation electronic circuits.

Table of Comparison

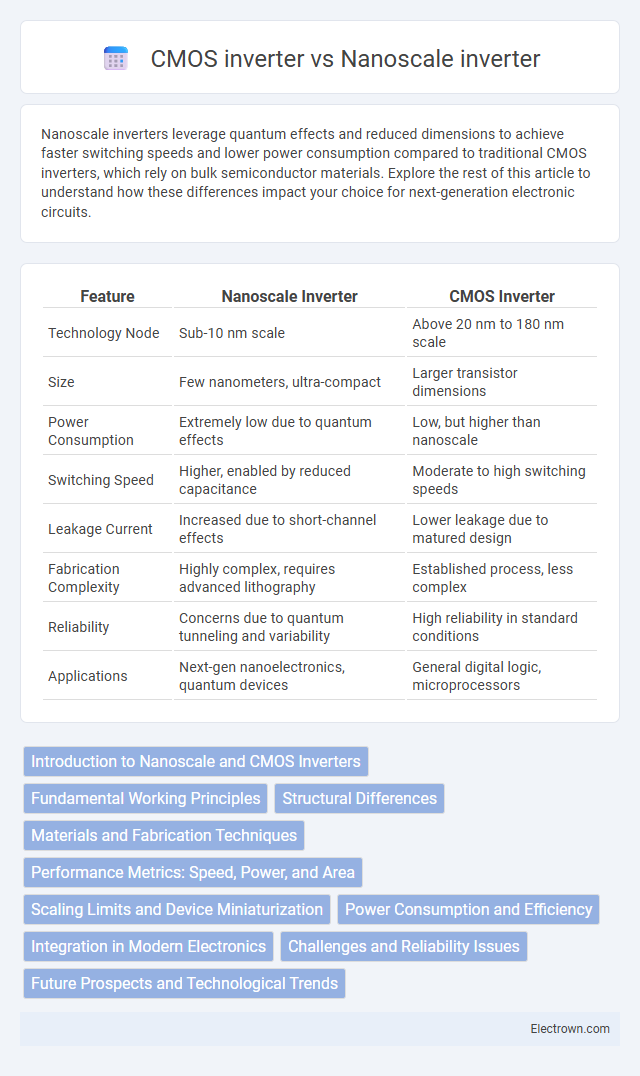

| Feature | Nanoscale Inverter | CMOS Inverter |

|---|---|---|

| Technology Node | Sub-10 nm scale | Above 20 nm to 180 nm scale |

| Size | Few nanometers, ultra-compact | Larger transistor dimensions |

| Power Consumption | Extremely low due to quantum effects | Low, but higher than nanoscale |

| Switching Speed | Higher, enabled by reduced capacitance | Moderate to high switching speeds |

| Leakage Current | Increased due to short-channel effects | Lower leakage due to matured design |

| Fabrication Complexity | Highly complex, requires advanced lithography | Established process, less complex |

| Reliability | Concerns due to quantum tunneling and variability | High reliability in standard conditions |

| Applications | Next-gen nanoelectronics, quantum devices | General digital logic, microprocessors |

Introduction to Nanoscale and CMOS Inverters

Nanoscale inverters leverage transistor dimensions measured in nanometers, enabling significantly faster switching speeds and reduced power consumption compared to conventional CMOS inverters. CMOS inverters, dominant in integrated circuit technology, utilize complementary pairs of p-type and n-type MOSFETs to achieve high noise margins and energy efficiency at larger technology nodes. The shift towards nanoscale inverters addresses scaling challenges in CMOS technology by enhancing device performance and mitigating short-channel effects inherent in sub-100nm transistors.

Fundamental Working Principles

Nanoscale inverters operate by leveraging quantum mechanical effects and electron tunneling in ultra-small dimensions, enabling faster switching speeds and lower power consumption than traditional CMOS inverters. CMOS (Complementary Metal-Oxide-Semiconductor) inverters function based on the complementary operation of p-type and n-type MOSFETs, switching output voltage levels through charge carrier modulation in semiconductor channels. The fundamental distinction lies in nanoscale inverters exploiting quantum properties at atomic scales, while CMOS inverters rely on classical semiconductor physics for logic signal inversion.

Structural Differences

Nanoscale inverters feature transistor channels measured in nanometers, often employing materials like graphene or carbon nanotubes, which enable enhanced electron mobility compared to traditional silicon-based CMOS inverters. CMOS inverters consist of complementary metal-oxide-semiconductor transistors with distinct NMOS and PMOS structures fabricated on bulk silicon substrates, leading to well-established scalability and low static power consumption. The structural differences influence switching speed, power efficiency, and integration density, positioning nanoscale inverters as promising candidates for next-generation ultra-compact, high-performance electronics.

Materials and Fabrication Techniques

Nanoscale inverters often utilize advanced materials such as carbon nanotubes, graphene, or transition metal dichalcogenides, enabling superior electrical properties and device scaling beyond traditional limits. Fabrication techniques for these nanoscale devices involve precision methods like atomic layer deposition, chemical vapor deposition, and electron-beam lithography to achieve atomic-level control, contrasting with the conventional photolithography commonly used in CMOS inverter production. Your choice between nanoscale and CMOS inverters depends on the desired performance, as nanoscale fabrication offers distinct material advantages but requires more complex and costly manufacturing processes.

Performance Metrics: Speed, Power, and Area

Nanoscale inverters exhibit superior speed due to reduced channel lengths, enabling faster switching compared to conventional CMOS inverters. Power consumption in nanoscale inverters is significantly lower, benefiting from decreased gate capacitance and leakage currents, contributing to enhanced energy efficiency. The compact footprint of nanoscale devices allows for greater density, minimizing area requirements and supporting advanced integration in modern electronic circuits.

Scaling Limits and Device Miniaturization

Nanoscale inverters demonstrate superior device miniaturization compared to traditional CMOS inverters due to their ability to maintain performance at dimensions below 10 nm, overcoming short-channel effects that limit CMOS scaling. CMOS inverters face significant scaling limits caused by gate leakage, variability, and power dissipation, which become critical issues as device geometries approach the atomic scale. Nanoscale inverter technologies, employing novel materials such as graphene or transition metal dichalcogenides, enable enhanced electrostatic control and reduced power consumption at ultra-small dimensions, surpassing the fundamental limitations of conventional silicon CMOS processes.

Power Consumption and Efficiency

Nanoscale inverters exhibit significantly lower power consumption compared to traditional CMOS inverters, primarily due to reduced leakage currents and smaller device dimensions. This enhanced efficiency allows your circuits to operate with greater speed and less heat generation, making them ideal for high-density and low-power applications. Advances in nanoscale technology optimize switching performance while maintaining energy efficiency, surpassing the capabilities of conventional CMOS inverters.

Integration in Modern Electronics

Nanoscale inverters exhibit superior integration capabilities in modern electronics due to their reduced size, allowing for higher transistor density compared to traditional CMOS inverters. This miniaturization leads to enhanced performance metrics such as faster switching speeds and lower power consumption, crucial for advanced microprocessors and portable devices. The compatibility of nanoscale technology with existing silicon-based processes ensures seamless incorporation into current semiconductor manufacturing workflows, driving innovation in compact and efficient electronic systems.

Challenges and Reliability Issues

Nanoscale inverters face significant challenges such as increased leakage currents, short-channel effects, and variability in device performance compared to traditional CMOS inverters, impacting their reliability in integrated circuits. Your choice between nanoscale and CMOS inverters must consider these reliability issues, as nanoscale devices are prone to higher susceptibility to noise and thermal fluctuations. Addressing these challenges requires advanced materials and fabrication techniques to ensure consistent operation and longevity in nanoscale inverter applications.

Future Prospects and Technological Trends

Nanoscale inverters exhibit superior switching speeds and reduced power consumption compared to traditional CMOS inverters, driving their prominence in future semiconductor technologies. Advanced materials like graphene and transition metal dichalcogenides (TMDs) enable enhanced electron mobility and scalability in nanoscale inverter designs, surpassing silicon-based CMOS limitations. Emerging trends emphasize integration of nanoscale inverters in flexible electronics and quantum computing devices, positioning them as key components in next-generation low-power, high-performance circuits.

Nanoscale inverter vs CMOS inverter Infographic

electrown.com

electrown.com