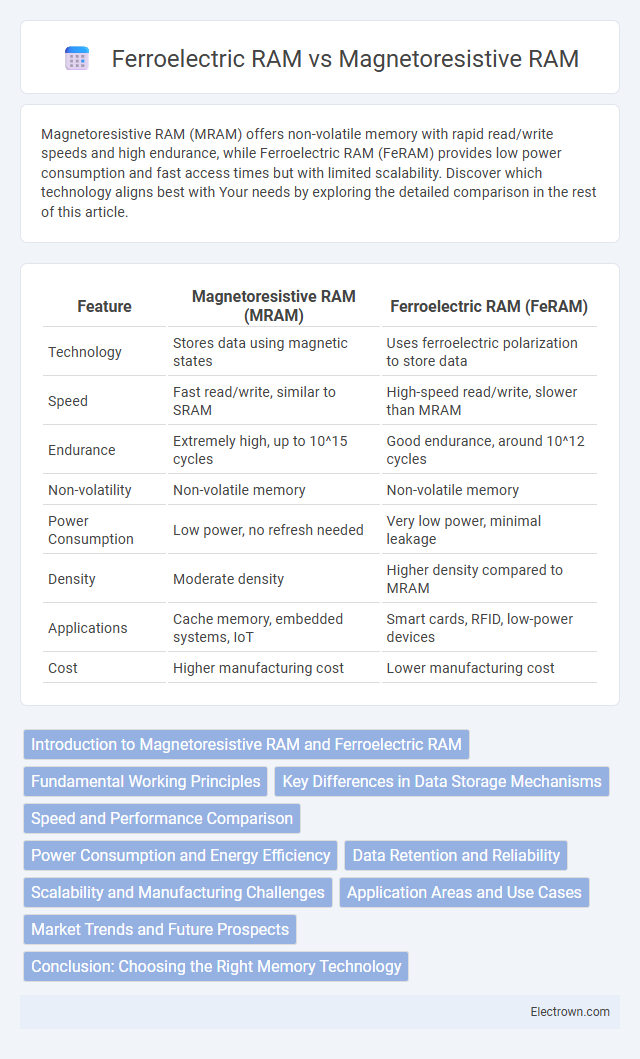

Magnetoresistive RAM (MRAM) offers non-volatile memory with rapid read/write speeds and high endurance, while Ferroelectric RAM (FeRAM) provides low power consumption and fast access times but with limited scalability. Discover which technology aligns best with Your needs by exploring the detailed comparison in the rest of this article.

Table of Comparison

| Feature | Magnetoresistive RAM (MRAM) | Ferroelectric RAM (FeRAM) |

|---|---|---|

| Technology | Stores data using magnetic states | Uses ferroelectric polarization to store data |

| Speed | Fast read/write, similar to SRAM | High-speed read/write, slower than MRAM |

| Endurance | Extremely high, up to 10^15 cycles | Good endurance, around 10^12 cycles |

| Non-volatility | Non-volatile memory | Non-volatile memory |

| Power Consumption | Low power, no refresh needed | Very low power, minimal leakage |

| Density | Moderate density | Higher density compared to MRAM |

| Applications | Cache memory, embedded systems, IoT | Smart cards, RFID, low-power devices |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

Introduction to Magnetoresistive RAM and Ferroelectric RAM

Magnetoresistive RAM (MRAM) uses magnetic states to store data, offering non-volatile memory with high endurance and fast read/write speeds, making it ideal for applications requiring durable and energy-efficient storage. Ferroelectric RAM (FeRAM) stores information through the polarization of a ferroelectric layer, delivering low power consumption and quick access times while retaining data without power. Your choice between MRAM and FeRAM depends on the specific needs for speed, endurance, and power efficiency in memory applications.

Fundamental Working Principles

Magnetoresistive RAM (MRAM) stores data by manipulating electron spin within magnetic tunnel junctions, relying on magnetic states to represent binary information. Ferroelectric RAM (FeRAM) operates by switching the polarization of a ferroelectric crystal, using electric fields to change the orientation of electric dipoles for data storage. MRAM's non-volatility is driven by spin-transfer torque or spin-orbit torque effects, while FeRAM employs hysteresis in ferroelectric materials to maintain polarization states.

Key Differences in Data Storage Mechanisms

Magnetoresistive RAM (MRAM) stores data by changing the magnetic orientation of magnetic layers, utilizing spintronic principles to represent binary states through magnetic resistance variations. Ferroelectric RAM (FeRAM) relies on the polarization of ferroelectric materials, where electric dipoles within the crystal lattice switch direction to encode information. MRAM offers non-volatile storage with faster write speeds and higher endurance, while FeRAM excels in low-power operation and radiation resistance due to its unique ferroelectric switching mechanism.

Speed and Performance Comparison

Magnetoresistive RAM (MRAM) offers faster read and write speeds compared to Ferroelectric RAM (FeRAM), with MRAM typically achieving nanosecond access times due to its magnetic storage mechanism. FeRAM, while possessing lower power consumption and high endurance, generally operates with slower write speeds because of its reliance on electric polarization changes. Your choice between the two technologies should consider MRAM for superior speed and performance demands in applications requiring rapid data access and reliability.

Power Consumption and Energy Efficiency

Magnetoresistive RAM (MRAM) offers lower power consumption by utilizing magnetic states to store data without requiring constant power, enabling energy-efficient non-volatile memory solutions. Ferroelectric RAM (FeRAM) also features low power usage, benefiting from its ferroelectric polarization mechanism to achieve fast write speeds with minimal energy. Your choice between MRAM and FeRAM should consider specific energy efficiency demands and application requirements, as MRAM excels in endurance and scaling while FeRAM provides ultra-low power writes for specialized uses.

Data Retention and Reliability

Magnetoresistive RAM (MRAM) offers excellent data retention with non-volatile storage capable of retaining information for over 10 years, making it highly reliable under varying environmental conditions. Ferroelectric RAM (FeRAM) also provides non-volatile memory with strong data retention but typically exhibits shorter endurance compared to MRAM, which can impact long-term reliability in write-intensive applications. Both technologies demonstrate robustness; however, MRAM's superior endurance and resistance to radiation-induced errors position it as a more reliable choice for critical data retention needs.

Scalability and Manufacturing Challenges

Magnetoresistive RAM (MRAM) offers better scalability due to its reliance on magnetic tunnel junctions, enabling high-density integration as technology nodes shrink, whereas Ferroelectric RAM (FeRAM) faces limitations in scaling because of ferroelectric layer thickness constraints and depolarization effects. Manufacturing challenges for MRAM include precise control of magnetic materials and tunnel barriers, requiring advanced deposition and patterning techniques to ensure uniformity and performance. FeRAM manufacturing struggles with material fatigue and integration of ferroelectric capacitors into CMOS processes, leading to yield and reliability issues at smaller nodes.

Application Areas and Use Cases

Magnetoresistive RAM (MRAM) excels in high-performance computing and automotive applications due to its fast read/write speeds and non-volatility, making it ideal for cache memory and real-time data storage. Ferroelectric RAM (FeRAM) is preferred in industrial and medical devices where low power consumption and high endurance are critical, supporting applications like sensor data logging and smart cards. Your choice between MRAM and FeRAM depends on whether speed or energy efficiency is the priority in the specific use case.

Market Trends and Future Prospects

Magnetoresistive RAM (MRAM) and Ferroelectric RAM (FeRAM) show distinct market trends driven by their unique advantages in speed, endurance, and power efficiency, with MRAM gaining momentum in high-density storage and automotive applications. FeRAM is favored in low-power, high-reliability sectors such as medical devices and industrial control systems, benefitting from its fast write speeds and durability. Your investment in these technologies should consider MRAM's rapid scalability and FeRAM's niche stability as both memory types look promising in the expanding non-volatile memory market.

Conclusion: Choosing the Right Memory Technology

Magnetoresistive RAM (MRAM) offers high endurance, fast read/write speeds, and excellent data retention, making it ideal for applications requiring frequent rewriting and long-term stability. Ferroelectric RAM (FeRAM) excels in low power consumption and ultra-fast write operations, suited for energy-efficient and real-time processing environments. Selecting between MRAM and FeRAM depends on specific use cases, balancing factors like speed, endurance, power efficiency, and data retention needs.

Magnetoresistive RAM vs Ferroelectric RAM Infographic

electrown.com

electrown.com