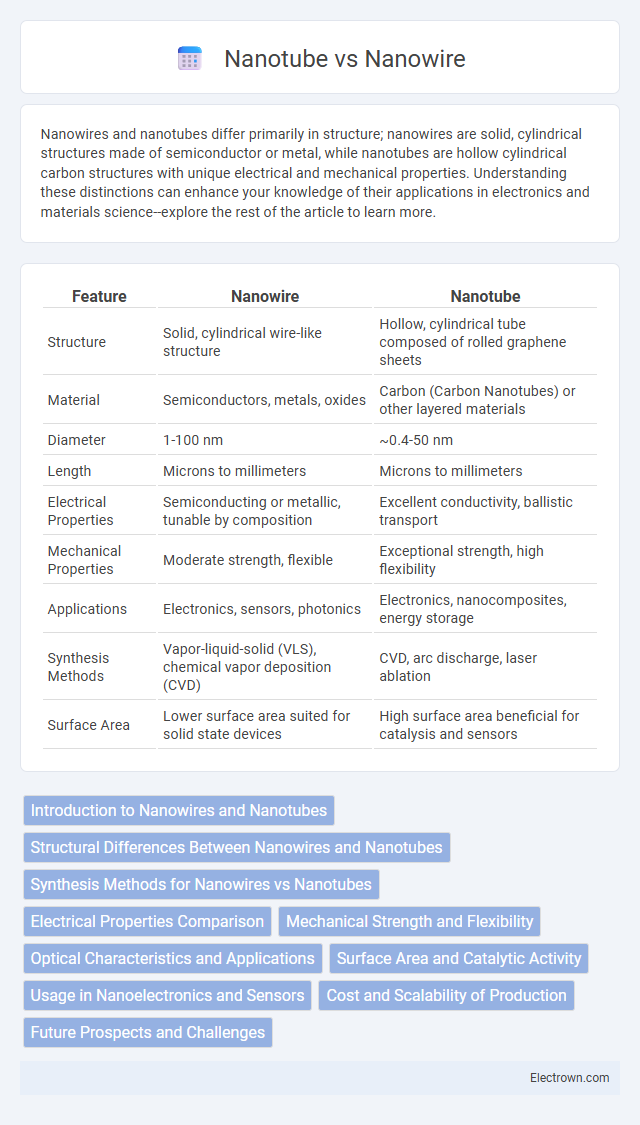

Nanowires and nanotubes differ primarily in structure; nanowires are solid, cylindrical structures made of semiconductor or metal, while nanotubes are hollow cylindrical carbon structures with unique electrical and mechanical properties. Understanding these distinctions can enhance your knowledge of their applications in electronics and materials science--explore the rest of the article to learn more.

Table of Comparison

| Feature | Nanowire | Nanotube |

|---|---|---|

| Structure | Solid, cylindrical wire-like structure | Hollow, cylindrical tube composed of rolled graphene sheets |

| Material | Semiconductors, metals, oxides | Carbon (Carbon Nanotubes) or other layered materials |

| Diameter | 1-100 nm | ~0.4-50 nm |

| Length | Microns to millimeters | Microns to millimeters |

| Electrical Properties | Semiconducting or metallic, tunable by composition | Excellent conductivity, ballistic transport |

| Mechanical Properties | Moderate strength, flexible | Exceptional strength, high flexibility |

| Applications | Electronics, sensors, photonics | Electronics, nanocomposites, energy storage |

| Synthesis Methods | Vapor-liquid-solid (VLS), chemical vapor deposition (CVD) | CVD, arc discharge, laser ablation |

| Surface Area | Lower surface area suited for solid state devices | High surface area beneficial for catalysis and sensors |

Introduction to Nanowires and Nanotubes

Nanowires and nanotubes are nanoscale structures with distinct morphologies and properties critical for advanced nanotechnology applications. Nanowires are one-dimensional crystalline structures composed of various materials such as semiconductors, metals, or oxides, characterized by diameters typically in the range of 1 to 100 nanometers and lengths that can extend to several micrometers. Nanotubes, commonly carbon-based, exhibit hollow cylindrical shapes with exceptional mechanical strength and electrical conductivity, making them ideal for use in electronics, energy storage, and nanomedicine.

Structural Differences Between Nanowires and Nanotubes

Nanowires are solid, cylindrical nanostructures with a uniform cross-section comprised of a single material or alloy, typically exhibiting high aspect ratios and quantum confinement effects along their length. Nanotubes, such as carbon nanotubes, feature hollow cylindrical structures formed by rolled graphene sheets, providing unique hollow cores and exceptional mechanical strength due to their layered atomic arrangement. The key structural difference lies in the solid core of nanowires versus the hollow nature of nanotubes, influencing their electrical conductivity, surface area, and mechanical properties.

Synthesis Methods for Nanowires vs Nanotubes

Nanowires are commonly synthesized using methods like vapor-liquid-solid (VLS) growth, chemical vapor deposition (CVD), and solvothermal processes, enabling precise control over diameter and length. Nanotubes are typically produced by chemical vapor deposition, arc discharge, or laser ablation, often requiring additional steps to achieve uniform wall thickness and chirality. Understanding these synthesis methods helps optimize your choice of nanostructures for targeted applications in electronics and materials science.

Electrical Properties Comparison

Nanowires exhibit excellent electrical conductivity and can be precisely tuned by altering their diameter, composition, and surface states, making them suitable for nanoelectronic applications. Carbon nanotubes offer exceptional electrical properties with ballistic transport and high current-carrying capacity, often outperforming nanowires in conductivity and electron mobility. The choice between nanowires and nanotubes depends on factors like desired electrical performance, fabrication complexity, and application-specific requirements in devices such as transistors or sensors.

Mechanical Strength and Flexibility

Nanowires exhibit higher mechanical flexibility due to their one-dimensional structure, allowing them to bend without breaking under moderate strain. Nanotubes, especially carbon nanotubes, possess exceptional mechanical strength, with tensile strength values exceeding 100 GPa, making them one of the strongest known materials. While nanotubes combine high strength with moderate flexibility, nanowires prioritize flexibility but generally have lower mechanical strength compared to nanotubes.

Optical Characteristics and Applications

Nanowires exhibit strong waveguiding capabilities and size-dependent photoluminescence, making them ideal for nanoscale lasers and photodetectors. Nanotubes, particularly carbon nanotubes, possess unique near-infrared fluorescence and strong nonlinear optical responses, enhancing their use in bioimaging and optical sensing. Both nanowires and nanotubes enable advanced optoelectronic devices due to their tunable bandgaps and high surface-to-volume ratios.

Surface Area and Catalytic Activity

Nanowires offer a higher surface area-to-volume ratio than nanotubes due to their solid structure, enhancing catalytic activity in applications like sensors and fuel cells. Nanotubes, with their hollow cylindrical shape, provide unique active sites and facilitate efficient electron transport, which can improve catalyst performance in certain chemical reactions. Your choice between nanowire and nanotube catalysts should consider the specific surface area requirements and the nature of catalytic processes involved.

Usage in Nanoelectronics and Sensors

Nanowires and nanotubes both play critical roles in nanoelectronics and sensor applications due to their unique electrical and mechanical properties. Nanowires offer superior electron mobility and easier integration with existing semiconductor technology, making them ideal for transistors and photodetectors, while nanotubes provide exceptional sensitivity and chemical stability, enhancing the performance of biosensors and gas sensors. Your choice depends on the specific device requirements, as nanowires excel in logic circuits and nanoscale interconnects, whereas nanotubes are preferred for flexible and highly sensitive sensor platforms.

Cost and Scalability of Production

Nanowire production generally offers lower costs due to established semiconductor fabrication techniques that enable large-scale manufacturing with high uniformity. Nanotube synthesis, particularly carbon nanotubes, remains expensive and challenging to scale because of complex growth processes and purification requirements. Advances in solution-based and chemical vapor deposition methods are gradually improving scalability for both nanowires and nanotubes, but nanowires currently have a commercial edge in cost-effective mass production.

Future Prospects and Challenges

Nanowires and nanotubes hold promising future prospects in nanotechnology applications such as electronics, energy storage, and sensors due to their unique electrical and mechanical properties. Challenges include scalable synthesis, precise control over dimensions, and integration into existing manufacturing processes, which are critical obstacles hindering widespread commercialization. Your ability to leverage these materials hinges on advances in overcoming these hurdles to unlock their full potential in next-generation technologies.

Nanowire vs Nanotube Infographic

electrown.com

electrown.com