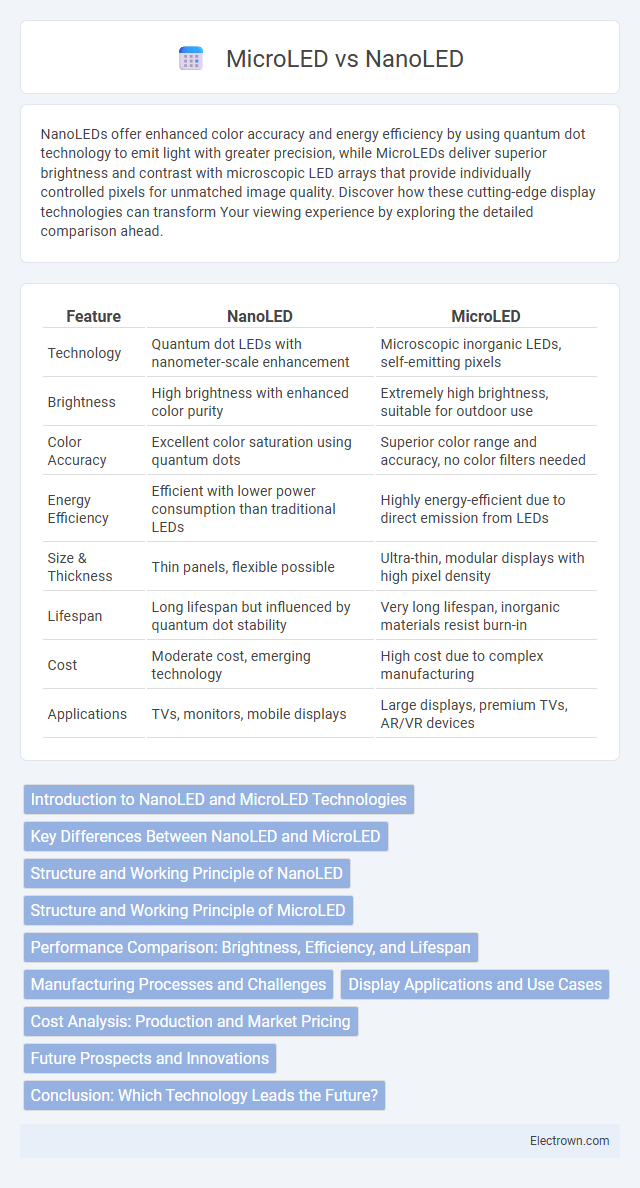

NanoLEDs offer enhanced color accuracy and energy efficiency by using quantum dot technology to emit light with greater precision, while MicroLEDs deliver superior brightness and contrast with microscopic LED arrays that provide individually controlled pixels for unmatched image quality. Discover how these cutting-edge display technologies can transform Your viewing experience by exploring the detailed comparison ahead.

Table of Comparison

| Feature | NanoLED | MicroLED |

|---|---|---|

| Technology | Quantum dot LEDs with nanometer-scale enhancement | Microscopic inorganic LEDs, self-emitting pixels |

| Brightness | High brightness with enhanced color purity | Extremely high brightness, suitable for outdoor use |

| Color Accuracy | Excellent color saturation using quantum dots | Superior color range and accuracy, no color filters needed |

| Energy Efficiency | Efficient with lower power consumption than traditional LEDs | Highly energy-efficient due to direct emission from LEDs |

| Size & Thickness | Thin panels, flexible possible | Ultra-thin, modular displays with high pixel density |

| Lifespan | Long lifespan but influenced by quantum dot stability | Very long lifespan, inorganic materials resist burn-in |

| Cost | Moderate cost, emerging technology | High cost due to complex manufacturing |

| Applications | TVs, monitors, mobile displays | Large displays, premium TVs, AR/VR devices |

Introduction to NanoLED and MicroLED Technologies

NanoLED technology utilizes nanoscale semiconductor particles to emit light with high efficiency and color purity, making it ideal for ultra-thin displays and compact lighting solutions. MicroLED technology comprises microscopic LEDs that provide superior brightness, energy efficiency, and longer lifespan compared to traditional OLED and LCD displays. Both technologies represent significant advancements in display innovation, offering enhanced performance for wearable devices, smartphones, and large-scale screens.

Key Differences Between NanoLED and MicroLED

NanoLED technology utilizes quantum dots to enhance color accuracy and brightness at the nanoscale, while MicroLED employs microscopic LEDs to achieve superior brightness and contrast with individual pixel control. MicroLED displays typically offer higher energy efficiency and longer lifespan compared to NanoLEDs, making them ideal for premium, long-lasting screens. Your choice depends on whether you prioritize vivid color precision or maximum durability and brightness in your display needs.

Structure and Working Principle of NanoLED

NanoLEDs consist of nanoscale light-emitting diodes with quantum dot structures that enable precise control of light emission through size-dependent quantum confinement effects. Their working principle relies on controlled electron-hole recombination in nanostructured semiconductor materials, resulting in high brightness and color purity. Unlike MicroLEDs, which use micron-sized LEDs with inorganic semiconductor layers, NanoLEDs leverage quantum dots for enhanced color tunability and energy efficiency.

Structure and Working Principle of MicroLED

MicroLED technology features microscopic LEDs that serve as individual pixels, creating brighter and more energy-efficient displays with superior contrast compared to NanoLEDs. Each MicroLED emits its own light, eliminating the need for backlighting and resulting in faster response times and vibrant colors. Your display experience benefits from this advanced structure and self-emissive working principle, offering unparalleled image clarity and durability.

Performance Comparison: Brightness, Efficiency, and Lifespan

MicroLED technology delivers superior brightness, often exceeding 1,000 nits, compared to NanoLED's lower luminance levels, making MicroLED ideal for high-visibility displays. In terms of efficiency, MicroLEDs consume less power due to their inorganic semiconductor structure, whereas NanoLEDs, based on organic materials, tend to have higher energy consumption and generate more heat. Regarding lifespan, MicroLEDs boast significantly longer durability, often surpassing 100,000 hours, whereas NanoLEDs typically have shorter operational lifespans due to organic material degradation.

Manufacturing Processes and Challenges

NanoLEDs utilize nanowire or quantum dot technologies, enabling precise control at the nanoscale but facing challenges in uniformity and large-scale production. MicroLEDs require intricate wafer bonding and transfer techniques for assembling microscopic LEDs onto display backplanes, demanding high precision to avoid defects and yield loss. Your choice depends on balancing NanoLED's potential for high color purity against MicroLED's complex manufacturing and scalability hurdles.

Display Applications and Use Cases

NanoLED technology excels in wearable devices and compact displays due to its ultra-small light-emitting diodes, enabling flexible and highly energy-efficient screen designs. MicroLED displays dominate large-scale applications such as televisions and digital billboards, offering superior brightness, contrast, and durability vital for immersive viewing experiences and outdoor visibility. Your choice depends on the requirement for display size and power efficiency, with NanoLEDs favoring compact, portable gadgets and MicroLEDs supporting expansive, high-performance screens.

Cost Analysis: Production and Market Pricing

NanoLED displays generally have lower production costs due to simpler manufacturing processes compared to MicroLEDs, which require precise placement of millions of tiny LEDs. MicroLED technology, while offering superior brightness and lifespan, incurs higher initial capital expenditure and is priced significantly above NanoLEDs in the current market. Your choice between these displays depends on balancing the premium cost of MicroLEDs against the more affordable NanoLEDs, especially for large-scale commercial applications.

Future Prospects and Innovations

MicroLED technology promises superior brightness, energy efficiency, and longer lifespan compared to NanoLEDs, making it a prime candidate for future high-end displays and augmented reality applications. Innovations in mass transfer techniques and pixel miniaturization are accelerating MicroLED commercialization, while NanoLEDs continue to evolve with improvements in material synthesis and quantum dot integration for enhanced color accuracy. Industry forecasts predict MicroLED's dominance in large-scale displays and wearable tech by 2030, leveraging its scalability and performance advancements.

Conclusion: Which Technology Leads the Future?

MicroLED technology leads the future with its superior brightness, energy efficiency, and longevity compared to NanoLED. The smaller pixel size and better color accuracy of MicroLED enable more immersive displays, making it the preferred choice for high-end TVs, wearables, and augmented reality devices. Your investment in MicroLED-based products ensures cutting-edge visual experiences and long-term performance benefits.

NanoLED vs MicroLED Infographic

electrown.com

electrown.com