Piezoelectric nanogenerators convert mechanical stress into electrical energy using crystalline materials, while triboelectric nanogenerators generate electricity through contact electrification and electrostatic induction between different materials. Discover how these technologies differ in efficiency, applications, and potential to power your next device by reading the full article.

Table of Comparison

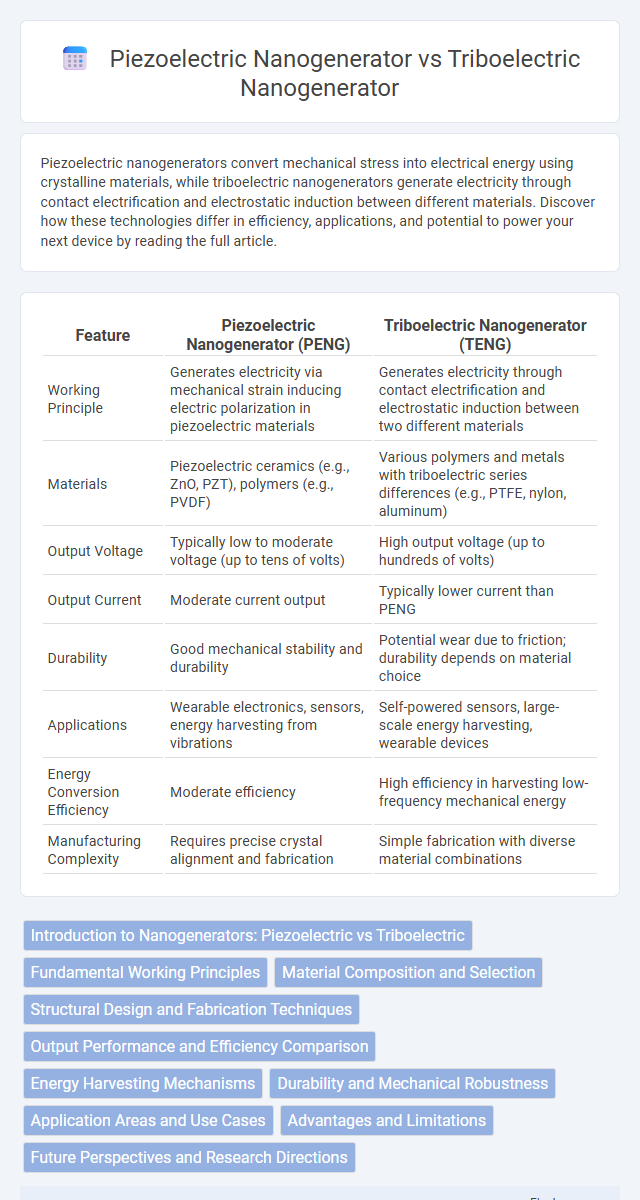

| Feature | Piezoelectric Nanogenerator (PENG) | Triboelectric Nanogenerator (TENG) |

|---|---|---|

| Working Principle | Generates electricity via mechanical strain inducing electric polarization in piezoelectric materials | Generates electricity through contact electrification and electrostatic induction between two different materials |

| Materials | Piezoelectric ceramics (e.g., ZnO, PZT), polymers (e.g., PVDF) | Various polymers and metals with triboelectric series differences (e.g., PTFE, nylon, aluminum) |

| Output Voltage | Typically low to moderate voltage (up to tens of volts) | High output voltage (up to hundreds of volts) |

| Output Current | Moderate current output | Typically lower current than PENG |

| Durability | Good mechanical stability and durability | Potential wear due to friction; durability depends on material choice |

| Applications | Wearable electronics, sensors, energy harvesting from vibrations | Self-powered sensors, large-scale energy harvesting, wearable devices |

| Energy Conversion Efficiency | Moderate efficiency | High efficiency in harvesting low-frequency mechanical energy |

| Manufacturing Complexity | Requires precise crystal alignment and fabrication | Simple fabrication with diverse material combinations |

Introduction to Nanogenerators: Piezoelectric vs Triboelectric

Nanogenerators convert mechanical energy into electrical energy using different mechanisms: piezoelectric nanogenerators (PENGs) rely on the direct piezoelectric effect in materials like ZnO and PZT, generating voltage through applied mechanical stress. Triboelectric nanogenerators (TENGs) harness contact electrification and electrostatic induction between two different materials, such as PTFE and nylon, to produce electricity from frictional forces. Your choice between PENG and TENG depends on application-specific factors like energy output, material flexibility, and environmental conditions.

Fundamental Working Principles

Piezoelectric nanogenerators convert mechanical stress into electrical energy through the deformation of piezoelectric materials, which generates an electric charge due to their crystalline structure. Triboelectric nanogenerators rely on contact electrification and electrostatic induction by creating charge separation when two different materials come into frictional contact and then separate. Understanding the fundamental working principles of these nanogenerators helps you choose the best technology for energy harvesting based on the specific mechanical stimuli in your application.

Material Composition and Selection

Piezoelectric nanogenerators primarily use materials with strong piezoelectric properties such as zinc oxide (ZnO), lead zirconate titanate (PZT), and polyvinylidene fluoride (PVDF). Triboelectric nanogenerators rely on the triboelectric effect, commonly using materials like polytetrafluoroethylene (PTFE), nylon, and other polymers with differing electron affinities to maximize charge transfer. Material selection in piezoelectric nanogenerators focuses on crystal structure and piezoelectric coefficients, while triboelectric nanogenerators prioritize surface charge density and dielectric constant for enhanced performance.

Structural Design and Fabrication Techniques

Piezoelectric nanogenerators typically utilize crystalline materials such as ZnO nanowires or PZT thin films arranged in vertical or horizontal arrays, fabricated via methods like hydrothermal growth, sputtering, or sol-gel processing to optimize mechanical-to-electrical energy conversion. Triboelectric nanogenerators employ diverse material pairs with contrasting electron affinities, often structured as layered films or patterned surfaces, created using techniques like lithography, nanoimprinting, or chemical vapor deposition to maximize contact electrification and charge transfer efficiency. Both nanogenerators integrate flexible substrates such as PDMS or PET to enhance durability and adaptability for wearable or implantable applications.

Output Performance and Efficiency Comparison

Piezoelectric nanogenerators convert mechanical stress directly into electrical energy with high output stability but moderate power density, while triboelectric nanogenerators rely on contact electrification and electrostatic induction, often achieving higher power density and energy harvesting efficiency under varied mechanical motions. Triboelectric nanogenerators typically demonstrate superior energy conversion efficiency in low-frequency and irregular mechanical environments, whereas piezoelectric types maintain better performance consistency in steady, high-frequency vibrations. Understanding these differences enables you to select the optimal nanogenerator based on specific output performance and energy harvesting efficiency requirements.

Energy Harvesting Mechanisms

Piezoelectric nanogenerators convert mechanical strain into electrical energy through the direct piezoelectric effect in materials like zinc oxide or lead zirconate titanate. Triboelectric nanogenerators generate electricity by contact electrification and electrostatic induction between two materials with differing electron affinities, such as polytetrafluoroethylene and aluminum. These energy harvesting mechanisms enable efficient conversion of ambient mechanical energy into usable electrical power for self-powered devices and sensors.

Durability and Mechanical Robustness

Piezoelectric nanogenerators (PENGs) typically exhibit high durability due to their solid-state materials, such as lead zirconate titanate (PZT) and zinc oxide (ZnO) nanowires, which provide stable mechanical robustness under cyclic loading conditions. Triboelectric nanogenerators (TENGs), often composed of polymeric materials like polytetrafluoroethylene (PTFE) and nylon, face challenges in long-term durability due to surface wear and material degradation from repetitive contact-separation cycles. Advances in material engineering, such as protective coatings and flexible composites, are enhancing the mechanical robustness of TENGs but generally, PENGs maintain superior longevity in harsh mechanical environments.

Application Areas and Use Cases

Piezoelectric nanogenerators (PENGs) excel in applications requiring stable, continuous power generation from mechanical vibrations, such as wearable health monitors, implantable medical devices, and structural health monitoring systems. Triboelectric nanogenerators (TENGs) are preferred for harvesting energy from irregular and low-frequency mechanical sources like human motion, wind, and ocean waves, powering self-sustaining sensors and portable electronics. Both technologies are pivotal in next-generation IoT devices, but PENGs favor environments with consistent mechanical inputs, while TENGs adapt to diverse and intermittent energy harvesting scenarios.

Advantages and Limitations

Piezoelectric nanogenerators excel in converting mechanical strain into electrical energy with high efficiency and stability, making them ideal for applications requiring consistent energy harvesting from vibrations or pressure changes; however, their performance diminishes under low-frequency or irregular mechanical inputs. Triboelectric nanogenerators offer a broader material selection and higher output voltage through contact electrification, enabling energy harvesting from diverse frictional motions, but they often suffer from lower durability and less stability due to material wear and environmental factors. Both technologies face challenges balancing output performance, durability, and scalability, which influences their suitability for various energy harvesting and self-powered sensor applications.

Future Perspectives and Research Directions

Future perspectives in piezoelectric nanogenerator research emphasize enhancing energy conversion efficiency and integrating flexible materials for wearable electronics. Triboelectric nanogenerators are advancing through surface engineering and charge density optimization to boost output power for large-scale applications. Your focus should align with hybrid systems combining both technologies to maximize energy harvesting capabilities in next-generation self-powered devices.

Piezoelectric nanogenerator vs Triboelectric nanogenerator Infographic

electrown.com

electrown.com