Vertical-Cavity Surface-Emitting Lasers (VCSELs) offer advantages like lower power consumption, easier testing, and better beam quality compared to Edge-Emitting Lasers (EELs), which typically provide higher output power and longer cavity lengths for specific applications. Your choice between VCSEL and EEL depends on factors such as desired performance, cost, and application; explore the article to understand these differences in detail.

Table of Comparison

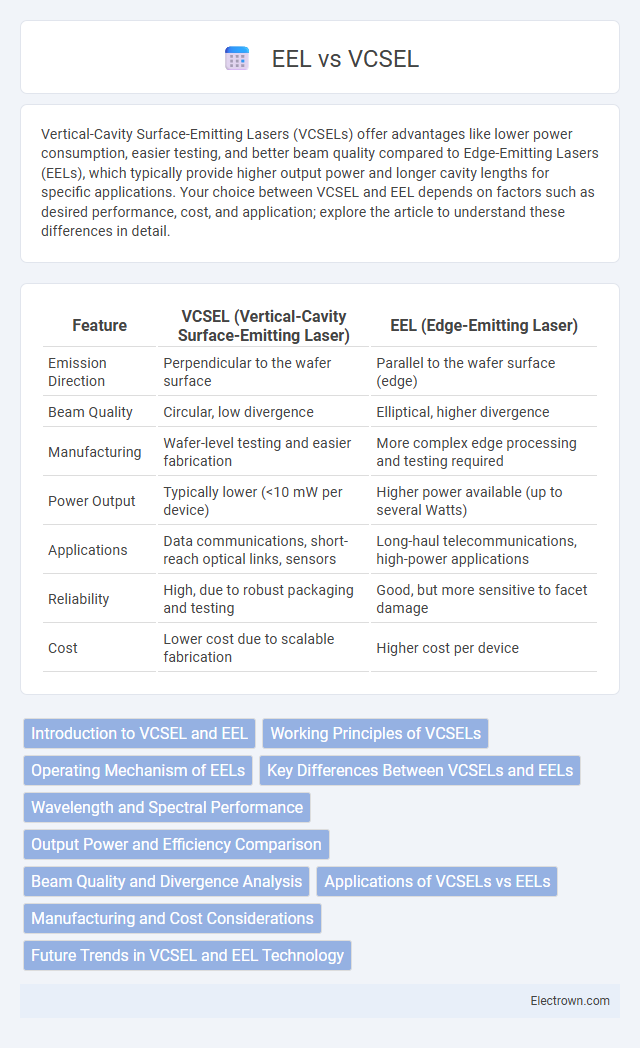

| Feature | VCSEL (Vertical-Cavity Surface-Emitting Laser) | EEL (Edge-Emitting Laser) |

|---|---|---|

| Emission Direction | Perpendicular to the wafer surface | Parallel to the wafer surface (edge) |

| Beam Quality | Circular, low divergence | Elliptical, higher divergence |

| Manufacturing | Wafer-level testing and easier fabrication | More complex edge processing and testing required |

| Power Output | Typically lower (<10 mW per device) | Higher power available (up to several Watts) |

| Applications | Data communications, short-reach optical links, sensors | Long-haul telecommunications, high-power applications |

| Reliability | High, due to robust packaging and testing | Good, but more sensitive to facet damage |

| Cost | Lower cost due to scalable fabrication | Higher cost per device |

Introduction to VCSEL and EEL

VCSEL (Vertical-Cavity Surface-Emitting Laser) emits light perpendicular to the semiconductor surface, enabling efficient coupling with optical fibers and superior beam quality compared to Edge-Emitting Laser (EEL), which emits light from the chip's edge. VCSELs offer advantages in power efficiency, scalability, and ease of testing during production, while EELs provide higher output power and longer emission wavelengths suitable for telecommunications. Your choice between VCSEL and EEL depends on application requirements such as data communication distance, power needs, and integration complexity.

Working Principles of VCSELs

VCSELs (Vertical-Cavity Surface-Emitting Lasers) operate by generating laser light perpendicular to the surface of the semiconductor chip, utilizing a short optical cavity formed by two highly reflective mirrors. Their structure enables efficient current injection and heat dissipation, resulting in lower threshold currents and high beam quality. You benefit from VCSELs' ability to produce reliable, low-power laser emission ideal for high-speed data communication and sensing applications.

Operating Mechanism of EELs

Edge Emitting Lasers (EELs) operate by generating light through electrical current passing across a p-n junction, causing electron-hole recombination in a forward-biased active region. Their emission occurs from the edge of the semiconductor chip, utilizing a Fabry-Perot cavity formed by cleaved facets to provide optical feedback and amplification. EELs typically have a longer cavity length than VCSELs, enabling higher output power and narrower beam divergence.

Key Differences Between VCSELs and EELs

VCSELs (Vertical-Cavity Surface-Emitting Lasers) emit light perpendicular to the wafer surface, enabling easier testing and high-density 2D array integration, while EELs (Edge-Emitting Lasers) emit light from the wafer edge, offering higher output power and longer cavity lengths. VCSELs typically provide lower threshold currents and better beam circularity, ideal for short-distance communications, whereas EELs deliver superior modulation speeds and higher optical power, beneficial for long-haul fiber optic transmission. The fabrication complexity of VCSELs is higher due to intricate mirror structures, whereas EELs have simpler fabrication but require edge-cleaving for emission.

Wavelength and Spectral Performance

VCSELs (Vertical-Cavity Surface-Emitting Lasers) typically operate at wavelengths ranging from 850 nm to 980 nm with narrow spectral linewidths around a few nanometers, offering high spectral purity essential for precise optical communications. In contrast, Edge-Emitting Lasers (EELs) cover a broader wavelength range, from 750 nm to 1600 nm, but exhibit wider spectral linewidths, often tens of nanometers, which can impact signal coherence. The superior spectral stability and narrow emission spectrum of VCSELs make them preferable for high-bandwidth, short-range data transmission, while EELs suit applications requiring tunable or extended wavelength options.

Output Power and Efficiency Comparison

Vertical-Cavity Surface-Emitting Lasers (VCSELs) typically offer lower output power compared to Edge-Emitting Lasers (EELs), with VCSELs generally producing a few milliwatts while EELs can reach several watts. VCSELs exhibit higher wall-plug efficiency due to their shorter cavity length and lower threshold current, making them more energy-efficient in low to moderate power applications. EELs, although less efficient at converting electrical input to optical output, are preferred for high-power applications requiring greater output power and beam quality.

Beam Quality and Divergence Analysis

VCSELs (Vertical-Cavity Surface-Emitting Lasers) exhibit superior beam quality due to their circular, low-divergence output, typically around 10deg to 15deg, which enables precise coupling into optical fibers and minimizes signal loss. EELs (Edge-Emitting Lasers), by contrast, produce elliptical beams with higher divergence, often exceeding 30deg along one axis, leading to greater challenges in beam shaping and fiber coupling. The inherent mode structure of VCSELs contributes to their stable, diffraction-limited beam profile, making them preferable for high-precision sensing and communication applications.

Applications of VCSELs vs EELs

VCSELs (Vertical-Cavity Surface-Emitting Lasers) are widely used in applications such as high-speed data communication, 3D sensing in smartphones, and optical mice due to their low power consumption, ease of testing, and ability to form dense arrays. EELs (Edge-Emitting Lasers) are preferred in long-haul telecommunications, industrial machining, and medical diagnostics where high output power and narrow linewidth are critical. Your choice between VCSELs and EELs depends on the specific application requirements involving beam quality, power, and integration complexity.

Manufacturing and Cost Considerations

VCSELs (Vertical-Cavity Surface-Emitting Lasers) feature simpler manufacturing processes due to their vertical emission structure, allowing for wafer-level testing and higher yield rates compared to EELs (Edge-Emitting Lasers), which require more complex fabrication steps and edge cleaving. The cost efficiency of VCSELs is amplified by scalable production and reduced assembly requirements, making them favorable for volume manufacturing. Your choice between VCSEL and EEL should consider these manufacturing efficiencies and cost impacts relative to the intended application.

Future Trends in VCSEL and EEL Technology

Future trends in VCSEL technology emphasize higher modulation speeds, integration with silicon photonics, and expanded applications in LiDAR and 3D sensing. EEL development is advancing towards increased output power, wavelength versatility for telecommunications, and improved energy efficiency for data centers. Both laser types benefit from innovations in materials and fabrication to meet evolving demands in optical communication and sensing.

VCSEL vs EEL Infographic

electrown.com

electrown.com