GaAs lasers offer higher efficiency and faster modulation speeds, making them ideal for applications requiring high-performance infrared emission. Explore the article to understand how your choice between GaAs and InP lasers impacts your specific optical communication or sensing needs.

Table of Comparison

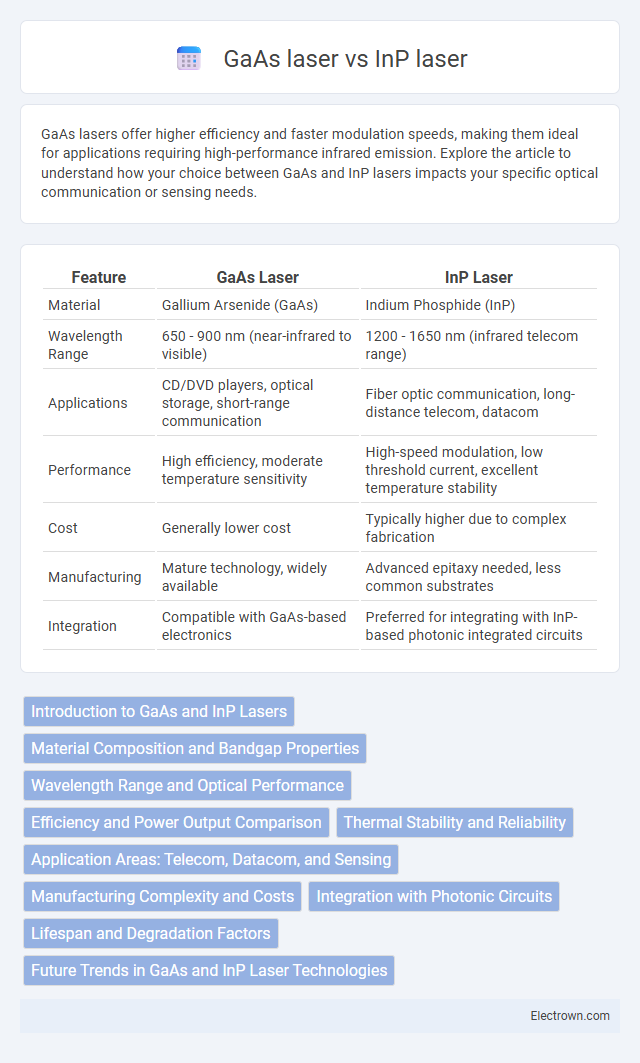

| Feature | GaAs Laser | InP Laser |

|---|---|---|

| Material | Gallium Arsenide (GaAs) | Indium Phosphide (InP) |

| Wavelength Range | 650 - 900 nm (near-infrared to visible) | 1200 - 1650 nm (infrared telecom range) |

| Applications | CD/DVD players, optical storage, short-range communication | Fiber optic communication, long-distance telecom, datacom |

| Performance | High efficiency, moderate temperature sensitivity | High-speed modulation, low threshold current, excellent temperature stability |

| Cost | Generally lower cost | Typically higher due to complex fabrication |

| Manufacturing | Mature technology, widely available | Advanced epitaxy needed, less common substrates |

| Integration | Compatible with GaAs-based electronics | Preferred for integrating with InP-based photonic integrated circuits |

Introduction to GaAs and InP Lasers

GaAs lasers utilize gallium arsenide as the semiconductor material, known for its efficient light emission at near-infrared wavelengths around 850 nm, making them ideal for short-distance optical communication and sensing applications. InP lasers, based on indium phosphide, operate primarily in the 1300 to 1550 nm wavelength range, offering superior performance for long-distance fiber optic communication due to lower signal attenuation and dispersion in optical fibers. Your choice between GaAs and InP lasers depends on the required wavelength, application range, and integration with existing photonic systems.

Material Composition and Bandgap Properties

GaAs lasers are made from gallium arsenide with a direct bandgap of about 1.43 eV, making them ideal for emitting light in the near-infrared range around 850 nm. InP lasers use indium phosphide, which has a wider bandgap of about 1.35 eV in combination with other materials like InGaAsP, allowing emission wavelengths from 1300 nm to 1550 nm, critical for telecom applications. Your choice depends on the desired wavelength and application, as GaAs suits shorter wavelengths while InP supports longer wavelengths with higher temperature stability.

Wavelength Range and Optical Performance

GaAs lasers typically operate within the wavelength range of 630 to 870 nm, offering high optical output power and efficiency suited for visible to near-infrared applications. InP lasers cover a broader spectrum from 900 to 1700 nm, excelling in telecommunications due to their superior performance in long-wavelength infrared regions with low threshold currents and high modulation speeds. Your choice between GaAs and InP lasers depends on the specific wavelength requirements and optical performance needed for high-speed data transmission or sensing applications.

Efficiency and Power Output Comparison

GaAs lasers typically exhibit higher power output due to superior electron mobility and direct bandgap properties, making them highly efficient for high-speed optical communication. InP lasers offer better efficiency at longer wavelengths, especially in the 1300 nm to 1550 nm range, due to their lower threshold current and improved thermal resistance. Power output in GaAs lasers can reach several watts in continuous-wave operation, while InP lasers often achieve comparable efficiency with stable performance suited for fiber optic applications.

Thermal Stability and Reliability

GaAs lasers exhibit superior thermal stability due to their wider bandgap, which minimizes performance degradation at elevated temperatures compared to InP lasers. InP lasers often face thermal challenges that affect their threshold current and output power, requiring advanced cooling solutions to maintain reliability. The inherent material properties of GaAs contribute to longer operational lifespans and consistent performance under thermal stress, making them preferable for high-temperature applications.

Application Areas: Telecom, Datacom, and Sensing

GaAs lasers are widely used in telecom and datacom for short-reach optical communication due to their high modulation speeds and efficient emission at 850 nm wavelengths. InP lasers dominate long-haul and metro telecom networks, offering superior performance at 1300 nm and 1550 nm wavelengths critical for low-loss fiber optic transmission. Your choice of laser depends on the required wavelength, data rate, and distance, with GaAs favoring high-speed, short-distance sensing and InP excelling in long-distance telecom applications.

Manufacturing Complexity and Costs

GaAs lasers typically involve lower manufacturing complexity and costs due to mature epitaxial growth techniques like MOCVD and widespread availability of GaAs substrates. In contrast, InP lasers present higher production challenges and expenses driven by more intricate material lattices and the need for precise control during epitaxial growth to maintain performance. The cost disparity is compounded by supply chain factors, where GaAs components benefit from long-established mass production scalability compared to the relatively specialized InP laser fabrication processes.

Integration with Photonic Circuits

GaAs lasers offer superior integration with photonic circuits due to their compatibility with high-efficiency light sources in the near-infrared range, facilitating dense integration on silicon photonics platforms. InP lasers excel in telecom wavelength applications around 1.55 um, allowing seamless integration with photonic circuits designed for optical communication systems. The choice between GaAs and InP lasers depends heavily on the operational wavelength requirements and the target photonic circuit architecture for optimal performance.

Lifespan and Degradation Factors

GaAs lasers typically offer a longer lifespan than InP lasers due to their robust crystal structure and resistance to thermal-induced defects. InP lasers are more susceptible to degradation through mechanisms such as defect generation and thermal quenching, which accelerate performance decline under high-power or high-temperature conditions. Both laser types experience degradation from factors like aging, electrical stress, and material lattice mismatches, but GaAs devices generally maintain stable output power and threshold current over extended operational periods.

Future Trends in GaAs and InP Laser Technologies

Future trends in GaAs and InP laser technologies emphasize enhanced integration with photonic circuits and higher modulation speeds for next-generation optical communication systems. GaAs lasers are advancing toward increased efficiency and wavelength tunability for applications in sensing and medical diagnostics, while InP lasers continue to dominate long-haul telecom due to superior performance in the 1.3 to 1.55 um wavelength range. Your choice between these materials will depend on the specific wavelength requirements and integration capabilities needed for future photonic device designs.

GaAs laser vs InP laser Infographic

electrown.com

electrown.com