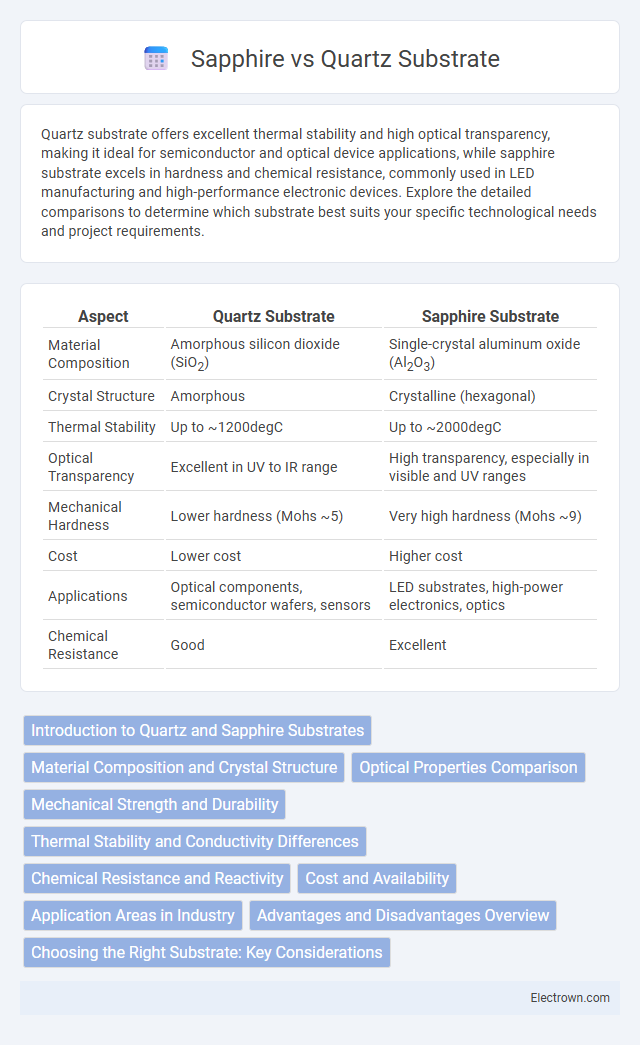

Quartz substrate offers excellent thermal stability and high optical transparency, making it ideal for semiconductor and optical device applications, while sapphire substrate excels in hardness and chemical resistance, commonly used in LED manufacturing and high-performance electronic devices. Explore the detailed comparisons to determine which substrate best suits your specific technological needs and project requirements.

Table of Comparison

| Aspect | Quartz Substrate | Sapphire Substrate |

|---|---|---|

| Material Composition | Amorphous silicon dioxide (SiO2) | Single-crystal aluminum oxide (Al2O3) |

| Crystal Structure | Amorphous | Crystalline (hexagonal) |

| Thermal Stability | Up to ~1200degC | Up to ~2000degC |

| Optical Transparency | Excellent in UV to IR range | High transparency, especially in visible and UV ranges |

| Mechanical Hardness | Lower hardness (Mohs ~5) | Very high hardness (Mohs ~9) |

| Cost | Lower cost | Higher cost |

| Applications | Optical components, semiconductor wafers, sensors | LED substrates, high-power electronics, optics |

| Chemical Resistance | Good | Excellent |

Introduction to Quartz and Sapphire Substrates

Quartz substrates offer exceptional thermal stability and excellent optical transparency, making them ideal for semiconductor and photonic applications. Sapphire substrates provide superior hardness and chemical resistance, often used in LED manufacturing and high-performance electronic devices. Your choice depends on factors like thermal conductivity, mechanical strength, and the specific requirements of your advanced technology project.

Material Composition and Crystal Structure

Quartz substrates are composed primarily of silicon dioxide (SiO2) in a crystalline form known as alpha-quartz, featuring a trigonal crystal structure that provides excellent thermal stability and piezoelectric properties. Sapphire substrates consist of single-crystal aluminum oxide (Al2O3) with a hexagonal crystal structure, offering superior hardness, chemical resistance, and high thermal conductivity. These differences in material composition and crystal lattice directly influence their suitability for various electronic, optical, and semiconductor applications.

Optical Properties Comparison

Quartz substrates exhibit superior ultraviolet (UV) transparency with a broad transmission range from 200 nm to 2500 nm, making them ideal for UV and visible light applications. Sapphire substrates offer exceptional optical clarity in the visible to near-infrared range, with high refractive index and low birefringence, enhancing performance in optoelectronic devices. Both materials provide excellent durability, but quartz is preferred for higher UV transmission while sapphire excels in strength and infrared transmission.

Mechanical Strength and Durability

Quartz substrates offer moderate mechanical strength with good thermal stability, making them suitable for applications requiring precision and resistance to thermal shock. Sapphire substrates exhibit superior mechanical strength and exceptional durability due to their hardness and scratch resistance, often used in high-stress environments like smartwatch screens and laser optics. Your choice between quartz and sapphire depends on the level of durability and toughness required for your specific application.

Thermal Stability and Conductivity Differences

Quartz substrates exhibit superior thermal stability withstanding temperatures up to 1,100degC, making them ideal for high-temperature applications, while sapphire substrates can endure even higher temperatures around 2,040degC, offering exceptional chemical resistance and mechanical strength. In terms of thermal conductivity, sapphire outperforms quartz significantly, with thermal conductivity values ranging from 25 to 35 W/m*K compared to quartz's lower 1.3 to 1.5 W/m*K, enabling more efficient heat dissipation in electronic and optical devices. These differences impact the choice of substrate materials in semiconductor and photonics industries, targeting thermal management and durability requirements.

Chemical Resistance and Reactivity

Quartz substrate exhibits exceptional chemical resistance, maintaining stability against most acids, alkalis, and solvents, making it ideal for harsh reactive environments. Sapphire substrate offers superior chemical inertness, particularly resistant to strong acids and bases, which ensures minimal reactivity in high-purity applications. Both substrates provide excellent chemical durability, but sapphire's higher resistance to aggressive chemicals makes it preferred in ultra-clean and corrosive conditions.

Cost and Availability

Quartz substrates offer a cost-effective solution due to abundant natural resources and well-established manufacturing processes, making them widely available for various industrial applications. Sapphire substrates, while more expensive, provide superior mechanical strength and thermal stability, but their limited availability and complex production techniques result in higher market prices. Industries requiring high-performance substrates often balance budget constraints with material properties when choosing between quartz and sapphire.

Application Areas in Industry

Quartz substrates are widely used in electronics and optoelectronics for their excellent thermal stability and piezoelectric properties, making them ideal for frequency control in oscillators and sensors. Sapphire substrates, known for their exceptional hardness and transparency, are preferred in LED manufacturing, semiconductor devices, and optical components where durability and high performance are critical. Choosing between quartz and sapphire substrates depends on your industry's specific requirements for mechanical strength, thermal conductivity, and optical clarity.

Advantages and Disadvantages Overview

Quartz substrates offer superior thermal stability and excellent optical transparency, making them ideal for applications in UV optics and semiconductor manufacturing. Sapphire substrates provide exceptional hardness, high chemical resistance, and superior electrical insulation, but they can be more expensive and challenging to fabricate. Your choice depends on balancing cost, durability, and specific application requirements such as thermal tolerance or optical clarity.

Choosing the Right Substrate: Key Considerations

Quartz substrates offer superior thermal stability and low thermal expansion, making them ideal for high-temperature applications and precision optics. Sapphire substrates provide exceptional hardness and chemical resistance, suitable for harsh environments and durable electronic components. Selecting the right substrate depends on factors like thermal performance, mechanical strength, optical clarity, and application-specific requirements.

Quartz vs Sapphire substrate Infographic

electrown.com

electrown.com