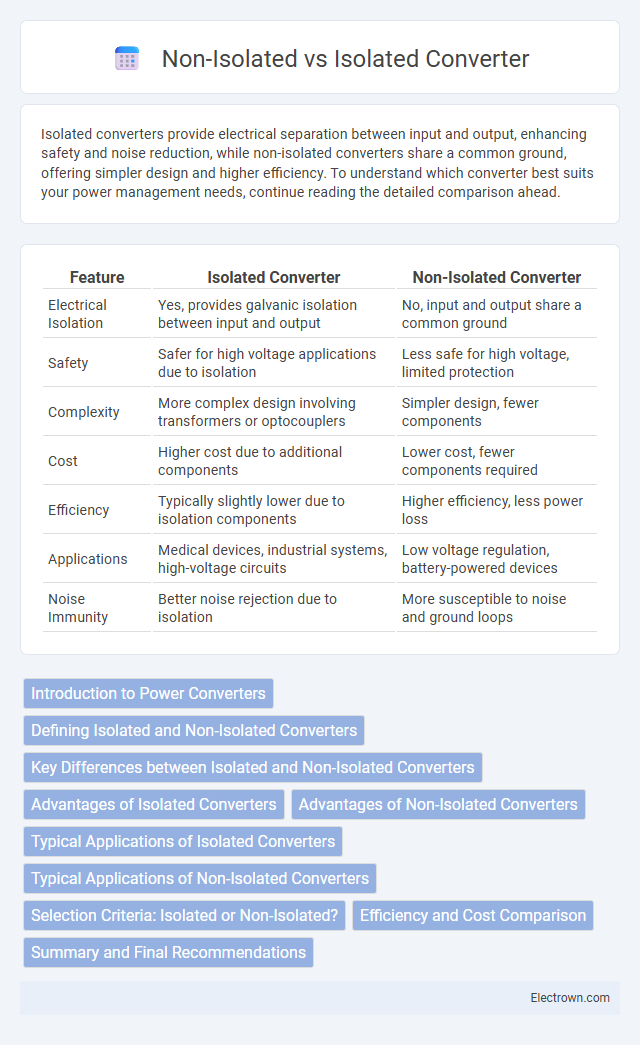

Isolated converters provide electrical separation between input and output, enhancing safety and noise reduction, while non-isolated converters share a common ground, offering simpler design and higher efficiency. To understand which converter best suits your power management needs, continue reading the detailed comparison ahead.

Table of Comparison

| Feature | Isolated Converter | Non-Isolated Converter |

|---|---|---|

| Electrical Isolation | Yes, provides galvanic isolation between input and output | No, input and output share a common ground |

| Safety | Safer for high voltage applications due to isolation | Less safe for high voltage, limited protection |

| Complexity | More complex design involving transformers or optocouplers | Simpler design, fewer components |

| Cost | Higher cost due to additional components | Lower cost, fewer components required |

| Efficiency | Typically slightly lower due to isolation components | Higher efficiency, less power loss |

| Applications | Medical devices, industrial systems, high-voltage circuits | Low voltage regulation, battery-powered devices |

| Noise Immunity | Better noise rejection due to isolation | More susceptible to noise and ground loops |

Introduction to Power Converters

Power converters are essential components in electronic systems, transforming electrical energy into a suitable form for various applications. Isolated converters provide galvanic separation between input and output, enhancing safety and reducing noise interference, making them ideal for sensitive or high-voltage environments. Non-isolated converters offer higher efficiency and simpler designs by directly connecting input and output grounds, suitable for low-voltage or cost-sensitive applications where isolation is not critical.

Defining Isolated and Non-Isolated Converters

Isolated converters provide electrical separation between input and output through components like transformers, enhancing safety and noise reduction in sensitive applications. Non-isolated converters maintain a direct electrical connection between input and output, offering simpler design and higher efficiency but less protection against electrical faults. Understanding these distinctions helps optimize Your power supply design based on isolation, efficiency, and safety requirements.

Key Differences between Isolated and Non-Isolated Converters

Isolated converters use galvanic isolation to separate input and output, enhancing safety and reducing electrical noise, while non-isolated converters share a common ground, offering simpler design and higher efficiency in low-voltage applications. Key differences include isolation level, safety standards compliance, and complexity of the circuitry, with isolated converters typically requiring transformers or optocouplers. Your choice depends on the need for electrical isolation, system complexity, and specific application requirements.

Advantages of Isolated Converters

Isolated converters provide enhanced safety by electrically separating input and output, preventing ground loop issues and reducing the risk of electric shock. They offer superior noise immunity, making them ideal for sensitive applications and environments with high electromagnetic interference. These converters also enable multiple output voltages and facilitate easier system integration in complex power architectures.

Advantages of Non-Isolated Converters

Non-isolated converters offer higher efficiency and lower cost due to simpler circuit design and fewer components, making them ideal for applications where galvanic isolation is not required. Their compact size and lighter weight contribute to easier integration into your power management system, especially in low-voltage DC-DC conversion scenarios. The direct connection between input and output grounds improves transient response and reduces electromagnetic interference compared to isolated counterparts.

Typical Applications of Isolated Converters

Isolated converters are commonly used in medical equipment, industrial automation, and telecommunications to ensure safety and prevent ground loops by electrically separating input and output circuits. Typical applications include powering sensitive devices that require protection from high-voltage transients and noise, such as hospital monitors, factory control systems, and communication base stations. You benefit from enhanced system reliability and compliance with strict regulatory standards through the use of isolated converters in these environments.

Typical Applications of Non-Isolated Converters

Non-isolated converters are commonly used in applications requiring efficient voltage step-down with minimal size and cost, such as point-of-load regulation in computing devices and battery-powered electronics. They are ideal for scenarios where electrical isolation is not critical, including LED drivers, telecommunications equipment, and DC motor controls. Their simple design enables high efficiency and fast transient response in low-voltage power supply modules.

Selection Criteria: Isolated or Non-Isolated?

When selecting between isolated and non-isolated converters, consider factors such as safety, noise immunity, and system complexity. Isolated converters provide galvanic isolation, enhancing protection and reducing electrical noise, ideal for high-voltage or sensitive applications. Your choice depends on whether isolation is crucial for safety and performance or if simpler, cost-effective non-isolated solutions meet your design requirements.

Efficiency and Cost Comparison

Isolated converters typically have lower efficiency due to energy losses in transformers but provide enhanced safety and noise reduction, making them essential for sensitive applications. Non-isolated converters offer higher efficiency and lower cost by eliminating isolation components, suitable for systems where galvanic isolation is unnecessary. Your choice between isolated and non-isolated converters depends on the trade-off between efficiency needs and budget constraints in your specific application.

Summary and Final Recommendations

Isolated converters provide galvanic isolation between input and output, enhancing safety and reducing noise, making them ideal for sensitive applications and medical or high-voltage systems. Non-isolated converters offer higher efficiency, simpler design, and lower cost, which suits low-voltage, cost-sensitive applications without isolation requirements. Your choice depends on the need for electrical isolation, safety standards, and system complexity.

Isolated vs Non-isolated converter Infographic

electrown.com

electrown.com