Gate turn-off thyristors (GTOs) allow control over both turn-on and turn-off processes by using a gate signal, unlike regular thyristors which can only be turned on and require external circuit interruption for turn-off. Understanding the key differences between GTOs and regular thyristors can help you optimize power control applications; explore the detailed comparison in the rest of this article.

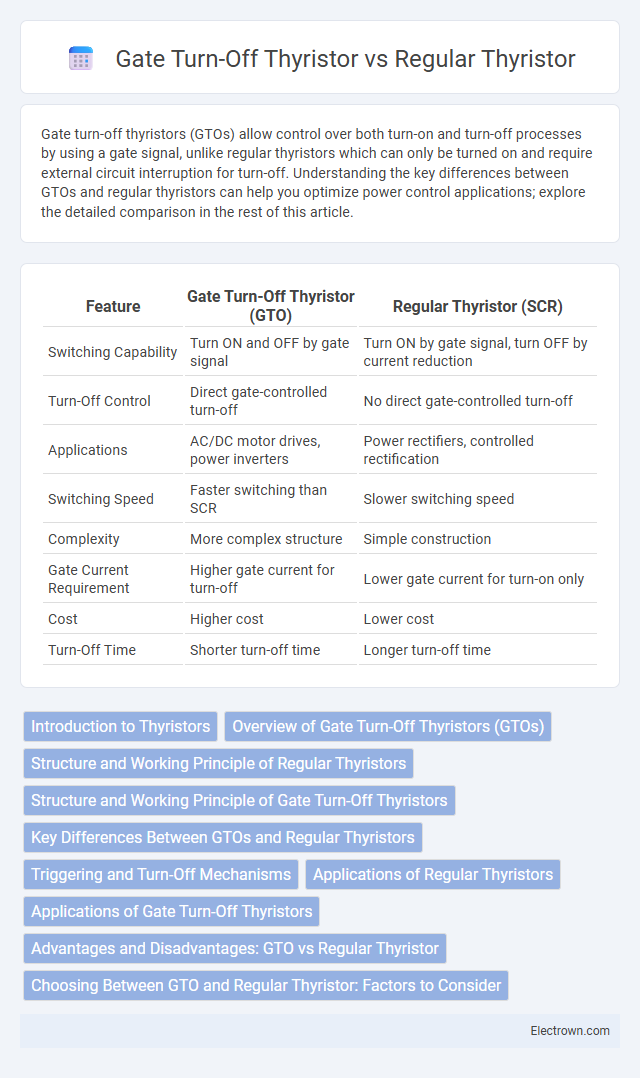

Table of Comparison

| Feature | Gate Turn-Off Thyristor (GTO) | Regular Thyristor (SCR) |

|---|---|---|

| Switching Capability | Turn ON and OFF by gate signal | Turn ON by gate signal, turn OFF by current reduction |

| Turn-Off Control | Direct gate-controlled turn-off | No direct gate-controlled turn-off |

| Applications | AC/DC motor drives, power inverters | Power rectifiers, controlled rectification |

| Switching Speed | Faster switching than SCR | Slower switching speed |

| Complexity | More complex structure | Simple construction |

| Gate Current Requirement | Higher gate current for turn-off | Lower gate current for turn-on only |

| Cost | Higher cost | Lower cost |

| Turn-Off Time | Shorter turn-off time | Longer turn-off time |

Introduction to Thyristors

Gate turn-off thyristors (GTOs) and regular thyristors are semiconductor devices used to control high power in electrical circuits. Regular thyristors can be turned on by a gate signal but require the current to drop below a certain threshold to turn off, while GTOs allow both turn-on and turn-off through gate signals, providing enhanced control. These differences make GTOs suitable for applications demanding fast switching and precise power regulation compared to traditional thyristors.

Overview of Gate Turn-Off Thyristors (GTOs)

Gate Turn-Off Thyristors (GTOs) are semiconductor devices that allow both turning on and turning off via the gate terminal, unlike regular thyristors which can only be turned on by the gate and require the current to drop below a threshold for turn-off. GTOs enable improved control in power electronics applications such as inverters, motor drives, and static switches by providing faster switching capabilities and greater efficiency. The construction of GTOs involves a multi-layered PNPN structure with enhanced gate control mechanisms that facilitate turning off the device by injecting reverse gate current.

Structure and Working Principle of Regular Thyristors

Regular thyristors consist of four alternating layers of P-type and N-type semiconductor materials forming a PNPN structure with three junctions, designed for controlled rectification. They operate by triggering a gate signal to switch from a high-impedance off state to a low-impedance on state, allowing current flow until the voltage drops below the holding level. You can use their latching characteristic for applications requiring controlled power delivery but without the ability to turn off the current via the gate.

Structure and Working Principle of Gate Turn-Off Thyristors

Gate turn-off thyristors (GTOs) feature a multilayer semiconductor structure similar to regular thyristors but incorporate a gate designed to both turn on and turn off the device by controlling the injection and extraction of charge carriers. Unlike regular thyristors, which require external commutation circuits to switch off, GTOs utilize a negative gate current to disrupt the regenerative feedback within the device, enabling gate-controlled turn-off. This distinct working principle allows GTOs to offer higher controllability in power electronics applications, especially in switching and controlling high voltage and current levels.

Key Differences Between GTOs and Regular Thyristors

Gate turn-off thyristors (GTOs) differ from regular thyristors primarily in their ability to be turned off by a gate signal, allowing precise control over switching operations. While regular thyristors require external commutation circuits to turn off, GTOs can be directly turned off via the gate, enhancing efficiency in power electronics applications. Your choice between these devices depends on the need for fast switching and controllability versus simpler circuit design.

Triggering and Turn-Off Mechanisms

Gate turn-off thyristors (GTOs) feature a bidirectional gate current allowing both turn-on and turn-off control, unlike regular thyristors which can only be turned on via gate triggering but require current interruption in the external circuit to turn off. The GTO's turn-off mechanism relies on applying a negative gate current to extract charge carriers from the device, enabling rapid switching and precise control in high-power applications. Regular thyristors depend on natural current zero crossing or external forcing circuit commutation for turn-off, lacking inherent gate-controlled deactivation.

Applications of Regular Thyristors

Regular thyristors are extensively used in high-power applications such as controlled rectifiers, AC motor speed controls, and light dimming circuits due to their ability to handle large currents and voltages efficiently. You will find them in industrial power control, variable frequency drives, and phase control devices where reliable switching and power regulation are essential. Their simple gate triggering mechanism and robust structure make them suitable for continuous power delivery in high-voltage environments.

Applications of Gate Turn-Off Thyristors

Gate Turn-Off Thyristors (GTOs) are primarily used in high-power applications requiring precise control of current, such as variable speed motor drives, traction systems in electric trains, and high-voltage DC transmission. Unlike regular thyristors, GTOs can be switched off by a gate signal, enabling improved efficiency and faster response in power conversion and inverter circuits. Your choice of GTOs enhances performance in industrial automation and renewable energy systems where rapid switching and reliable turn-off capabilities are critical.

Advantages and Disadvantages: GTO vs Regular Thyristor

Gate turn-off thyristors (GTOs) offer the advantage of controllable turn-off capability, allowing your power circuits to switch off without relying on external commutation, unlike regular thyristors which can only be turned off by reducing the current below the holding level. GTOs typically have higher switching losses and require complex gate drive circuits compared to regular thyristors, which are simpler and more robust for high-current applications. The choice between GTO and regular thyristor depends on the need for turn-off control versus overall efficiency and circuit complexity.

Choosing Between GTO and Regular Thyristor: Factors to Consider

Choosing between a Gate Turn-Off Thyristor (GTO) and a regular thyristor depends on factors such as the need for controllable turn-off capability, switching speed, and application voltage levels. GTOs allow for both turn-on and turn-off via gate signals, making them suitable for dynamic power control in high-power applications, while regular thyristors only turn on through the gate and require current interruption to turn off. Consider device complexity, cost, and thermal management requirements when selecting the optimal thyristor type for power electronics circuits.

Gate turn-off thyristor vs regular thyristor Infographic

electrown.com

electrown.com