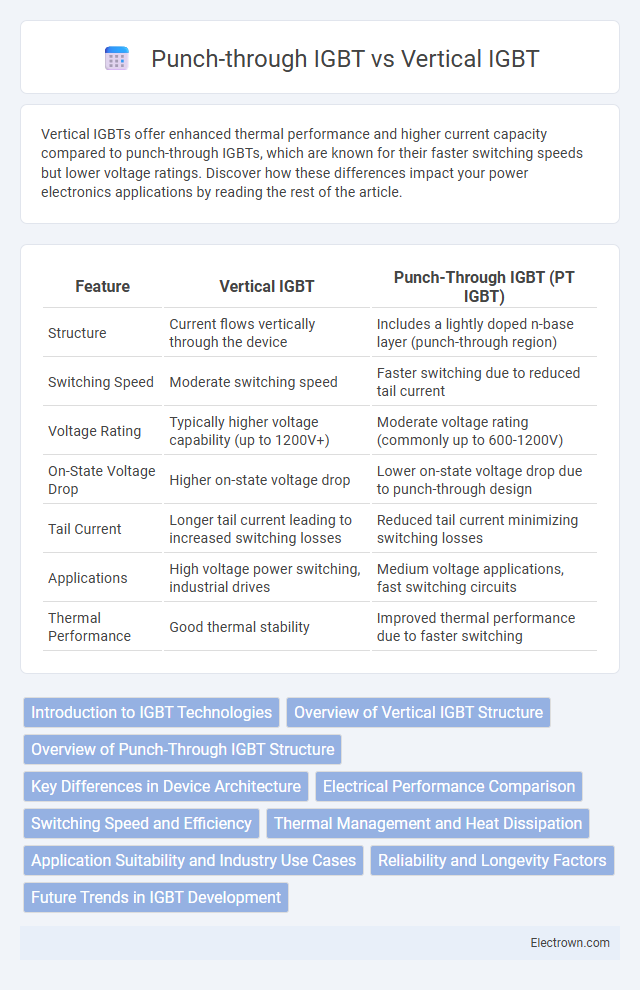

Vertical IGBTs offer enhanced thermal performance and higher current capacity compared to punch-through IGBTs, which are known for their faster switching speeds but lower voltage ratings. Discover how these differences impact your power electronics applications by reading the rest of the article.

Table of Comparison

| Feature | Vertical IGBT | Punch-Through IGBT (PT IGBT) |

|---|---|---|

| Structure | Current flows vertically through the device | Includes a lightly doped n-base layer (punch-through region) |

| Switching Speed | Moderate switching speed | Faster switching due to reduced tail current |

| Voltage Rating | Typically higher voltage capability (up to 1200V+) | Moderate voltage rating (commonly up to 600-1200V) |

| On-State Voltage Drop | Higher on-state voltage drop | Lower on-state voltage drop due to punch-through design |

| Tail Current | Longer tail current leading to increased switching losses | Reduced tail current minimizing switching losses |

| Applications | High voltage power switching, industrial drives | Medium voltage applications, fast switching circuits |

| Thermal Performance | Good thermal stability | Improved thermal performance due to faster switching |

Introduction to IGBT Technologies

Vertical IGBT and punch-through IGBT represent two crucial technologies in power semiconductor devices designed to efficiently switch and control electrical energy. Vertical IGBTs offer low on-state voltage drop and high current capacity by allowing current flow vertically through the device, making them suitable for high-power applications. Punch-through IGBTs improve switching speed and reduce conduction losses through a lightly doped drift region, enhancing performance in medium to high voltage ranges for your power electronics needs.

Overview of Vertical IGBT Structure

Vertical IGBTs (Insulated Gate Bipolar Transistors) feature a layered semiconductor structure that facilitates current flow vertically through the device, enhancing power handling and efficiency. This design contrasts with punch-through IGBTs, where a thin, lightly doped drift region allows charge carriers to "punch through" the device during high voltage operation, impacting switching characteristics. Understanding the vertical IGBT structure helps you choose the right device for applications requiring robust performance and thermal management.

Overview of Punch-Through IGBT Structure

Punch-through IGBT features a structure characterized by a lightly doped n- drift region between the collector and the p-base, which enhances conductivity modulation and switching performance. This design allows for lower on-state voltage drop and improved efficiency in high-voltage applications compared to conventional vertical IGBTs. However, the punch-through structure can lead to higher leakage current and requires careful control of the drift region's thickness and doping concentration to optimize device performance.

Key Differences in Device Architecture

Vertical IGBTs feature a multilayer structure with a vertical current flow path, allowing for higher voltage blocking capabilities and improved conduction efficiency. Punch-through IGBTs incorporate a specially designed "punch-through" region that reduces on-state voltage drop by enabling charge carrier flow through a lightly doped drift region. The main architectural difference lies in the drift region design, where vertical IGBTs emphasize robust layering for blocking voltage, and punch-through IGBTs optimize carrier injection for faster switching and lower conduction losses.

Electrical Performance Comparison

Vertical IGBTs offer superior electrical performance with lower on-state voltage drop and higher current density compared to punch-through IGBTs, resulting in improved efficiency and reduced conduction losses. Punch-through IGBTs exhibit faster switching speeds but typically suffer from higher leakage currents and lower avalanche capability. In applications requiring high power density and robust thermal management, vertical IGBTs demonstrate enhanced reliability and better overall electrical efficiency.

Switching Speed and Efficiency

Vertical IGBTs typically offer higher switching speeds due to their optimized vertical current flow path, which reduces charge carrier transit time compared to punch-through IGBTs. These devices also provide improved efficiency by minimizing conduction losses and enabling faster turn-off times, resulting in lower switching losses during high-frequency operation. Punch-through IGBTs, while robust and suitable for high-voltage applications, generally exhibit slower switching speeds and slightly lower efficiency due to their design characteristics that increase charge storage effects.

Thermal Management and Heat Dissipation

Vertical IGBTs offer superior thermal management due to their structure, which enables efficient heat dissipation through the silicon substrate, reducing junction temperature during high-power operation. Punch-through IGBTs, while simpler in design, typically exhibit higher thermal resistance, leading to increased hotspot formation and less effective heat spread under heavy load conditions. Optimizing your device selection with vertical IGBTs can enhance reliability and thermal performance in demanding power applications.

Application Suitability and Industry Use Cases

Vertical IGBTs excel in high-voltage industrial drives, renewable energy inverters, and electric vehicles due to their superior current handling and thermal performance. Punch-through IGBTs find suitability in medium-voltage applications like motor control and traction systems, offering faster switching speeds and lower on-state losses. Your selection depends on balancing switching frequency and voltage requirements specific to power electronics applications.

Reliability and Longevity Factors

Vertical IGBTs typically offer enhanced reliability due to their robust design that reduces hot spots and improves thermal management, directly contributing to longer device lifespan. Punch-through IGBTs, while allowing faster switching speeds, often face higher risks of latch-up and increased leakage currents, which can impact their long-term reliability under high-stress conditions. To maximize your system's durability, choosing a vertical IGBT may provide better longevity and consistent performance in demanding power applications.

Future Trends in IGBT Development

Vertical IGBTs are evolving towards higher efficiency and better thermal management, enabling their use in electric vehicles and renewable energy systems. Punch-through IGBTs, characterized by faster switching speeds and lower conduction losses, are being optimized for high-frequency applications like industrial motor drives and power converters. Your choice between these technologies will depend on the specific demands of future power electronics, where advancements focus on improving reliability, reducing switching losses, and enhancing overall device robustness.

Vertical IGBT vs punch-through IGBT Infographic

electrown.com

electrown.com