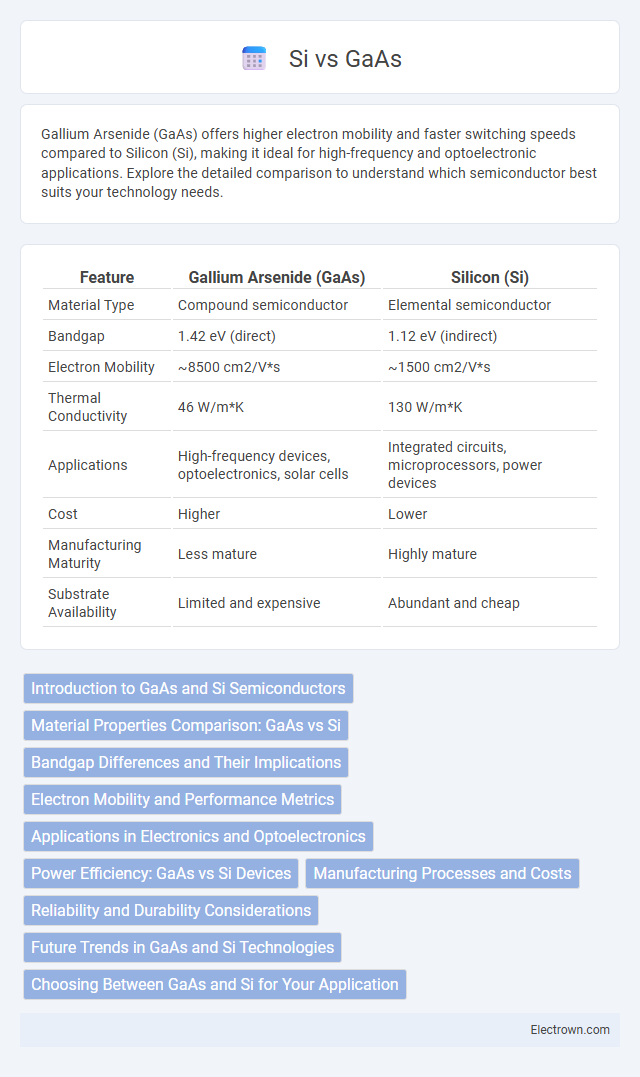

Gallium Arsenide (GaAs) offers higher electron mobility and faster switching speeds compared to Silicon (Si), making it ideal for high-frequency and optoelectronic applications. Explore the detailed comparison to understand which semiconductor best suits your technology needs.

Table of Comparison

| Feature | Gallium Arsenide (GaAs) | Silicon (Si) |

|---|---|---|

| Material Type | Compound semiconductor | Elemental semiconductor |

| Bandgap | 1.42 eV (direct) | 1.12 eV (indirect) |

| Electron Mobility | ~8500 cm2/V*s | ~1500 cm2/V*s |

| Thermal Conductivity | 46 W/m*K | 130 W/m*K |

| Applications | High-frequency devices, optoelectronics, solar cells | Integrated circuits, microprocessors, power devices |

| Cost | Higher | Lower |

| Manufacturing Maturity | Less mature | Highly mature |

| Substrate Availability | Limited and expensive | Abundant and cheap |

Introduction to GaAs and Si Semiconductors

Gallium Arsenide (GaAs) and Silicon (Si) are two primary semiconductor materials used in modern electronics, each with distinct properties shaping their applications. GaAs offers higher electron mobility and superior performance at high frequencies, making it ideal for RF and microwave devices, while Si dominates the semiconductor industry due to its abundance, cost-effectiveness, and well-established manufacturing processes. Understanding the fundamental differences between GaAs and Si can help you select the appropriate semiconductor material based on factors like speed, efficiency, and cost for your specific electronic applications.

Material Properties Comparison: GaAs vs Si

Gallium arsenide (GaAs) exhibits higher electron mobility and a direct bandgap of 1.42 eV, enabling faster electronic and optoelectronic device performance compared to silicon (Si), which has an indirect bandgap of 1.12 eV and lower electron mobility. GaAs demonstrates superior frequency response and efficiency in high-speed applications, while Si offers better thermal conductivity and cost-effectiveness for large-scale integration. Your choice between GaAs and Si depends on the specific application, balancing speed, power consumption, and manufacturing considerations.

Bandgap Differences and Their Implications

Gallium Arsenide (GaAs) has a direct bandgap of approximately 1.42 eV, while Silicon (Si) has an indirect bandgap of about 1.12 eV, influencing their optical and electronic properties significantly. The direct bandgap in GaAs allows for efficient light emission and absorption, making it ideal for optoelectronic devices like LEDs and laser diodes. Your choice between GaAs and Si will impact device performance, especially in high-frequency and photonic applications where electron mobility and bandgap characteristics are critical.

Electron Mobility and Performance Metrics

Gallium Arsenide (GaAs) exhibits electron mobility around 8500 cm2/V*s, significantly surpassing Silicon's (Si) approximately 1500 cm2/V*s, enabling faster electron transport and higher frequency operation. This elevated electron mobility translates into superior performance metrics for GaAs devices, including higher cutoff frequencies and improved gain in RF and microwave applications. Consequently, GaAs is preferred in high-speed and high-frequency semiconductor devices where performance demands exceed silicon's capabilities.

Applications in Electronics and Optoelectronics

Gallium Arsenide (GaAs) is extensively used in high-frequency and high-speed electronics such as microwave and millimeter-wave devices, including RF amplifiers, satellite communications, and radar systems due to its high electron mobility and direct bandgap. Silicon (Si), with its mature fabrication technology, dominates integrated circuits in computing, digital electronics, and power devices but has limited optical capabilities compared to GaAs. GaAs's direct bandgap enables efficient optoelectronic applications like LEDs, laser diodes, and photovoltaic cells, whereas Si is primarily used in electronics where its indirect bandgap limits photonic efficiency.

Power Efficiency: GaAs vs Si Devices

GaAs devices demonstrate superior power efficiency compared to Si devices due to their higher electron mobility and direct bandgap properties, allowing faster switching speeds and reduced power loss. This results in lower heat generation and enhanced performance in high-frequency and high-power applications. Choosing GaAs can significantly improve Your system's overall energy efficiency and operational reliability.

Manufacturing Processes and Costs

Gallium Arsenide (GaAs) manufacturing involves complex epitaxial growth and wafer handling processes, resulting in significantly higher production costs compared to Silicon (Si), which benefits from mature, large-scale fabrication infrastructure. Silicon's abundance and well-established CMOS technology enable cost-effective mass production, while GaAs wafers are smaller and more expensive, limiting their use to high-performance applications like RF and optoelectronics. Your choice between GaAs and Si will depend on balancing performance gains against the increased manufacturing expenses associated with GaAs.

Reliability and Durability Considerations

Gallium Arsenide (GaAs) offers superior radiation resistance and thermal stability compared to Silicon (Si), making it highly reliable in high-frequency and harsh environment applications. GaAs devices typically exhibit lower leakage currents and better performance retention under prolonged stress, enhancing durability in aerospace and military uses. Conversely, Silicon remains dominant in general electronics due to its well-established manufacturing processes and cost-effectiveness despite slightly lower resilience to extreme conditions.

Future Trends in GaAs and Si Technologies

GaAs technology is advancing rapidly with improvements in high-frequency performance and integration for 5G and satellite communications, while Si technology dominates in cost-effective, large-scale semiconductor manufacturing for AI and IoT applications. The emergence of SiGe and GaN materials enhances Si and GaAs platforms by combining high-speed and power efficiency characteristics, driving innovation in heterogeneous integration and system-on-chip designs. Future trends indicate GaAs will excel in RF front-ends and optoelectronics, whereas Si continues to evolve through scaling and novel transistor architectures like FinFET and gate-all-around (GAA) transistors.

Choosing Between GaAs and Si for Your Application

Gallium Arsenide (GaAs) offers superior electron mobility and higher frequency performance compared to Silicon (Si), making it ideal for high-speed and microwave applications. Silicon remains the preferred choice for cost-effective, large-scale integration and power efficiency in consumer electronics and digital circuits. Your decision should weigh GaAs's high-frequency advantages against Silicon's versatility and manufacturing economy.

GaAs vs Si Infographic

electrown.com

electrown.com