Metal cans offer superior heat dissipation and durability compared to TO-220 packages, making them ideal for high-power and high-reliability applications. Discover how choosing the right package can enhance your electronic design performance by reading the full article.

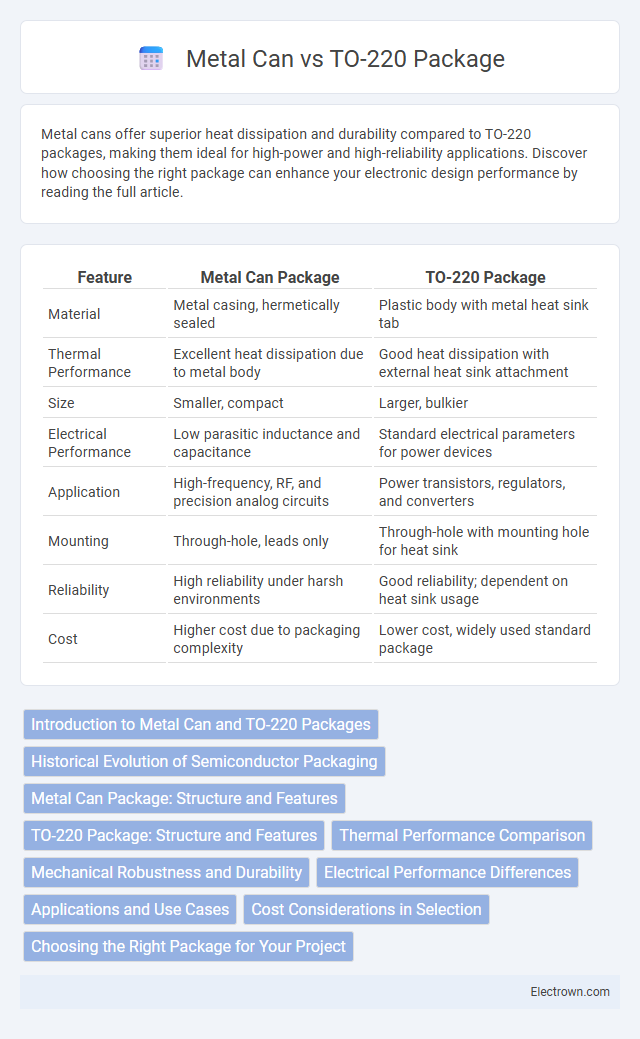

Table of Comparison

| Feature | Metal Can Package | TO-220 Package |

|---|---|---|

| Material | Metal casing, hermetically sealed | Plastic body with metal heat sink tab |

| Thermal Performance | Excellent heat dissipation due to metal body | Good heat dissipation with external heat sink attachment |

| Size | Smaller, compact | Larger, bulkier |

| Electrical Performance | Low parasitic inductance and capacitance | Standard electrical parameters for power devices |

| Application | High-frequency, RF, and precision analog circuits | Power transistors, regulators, and converters |

| Mounting | Through-hole, leads only | Through-hole with mounting hole for heat sink |

| Reliability | High reliability under harsh environments | Good reliability; dependent on heat sink usage |

| Cost | Higher cost due to packaging complexity | Lower cost, widely used standard package |

Introduction to Metal Can and TO-220 Packages

Metal can packages offer superior thermal conductivity and hermetic sealing, making them ideal for high-reliability applications in aerospace and military electronics. TO-220 packages provide excellent heat dissipation through a large metal tab and are commonly used in power semiconductors like voltage regulators and transistors. When selecting components, your choice between metal can and TO-220 packages depends on factors such as thermal requirements, environmental protection, and mechanical durability.

Historical Evolution of Semiconductor Packaging

The Metal Can package, known as the TO-18 or TO-5, was among the earliest semiconductor housings, prized for its hermetic sealing and heat dissipation in the 1950s. The TO-220 package emerged in the 1970s, offering improved thermal management and easier mounting for power transistors and voltage regulators with its larger plastic body and metal tab for heat sinking. Your choice between Metal Can and TO-220 reflects the evolutionary shift from durability and protection to enhanced thermal performance and practical assembly in semiconductor packaging technology.

Metal Can Package: Structure and Features

The Metal Can package, often known as the TO-18 or TO-39, features a cylindrical, hermetically sealed metal enclosure that provides excellent thermal conductivity and mechanical protection. This structure enhances device reliability by shielding sensitive semiconductor components from environmental contaminants, moisture, and electromagnetic interference. Its robust design supports efficient heat dissipation, making it ideal for high-frequency or high-power applications requiring stable performance under harsh conditions.

TO-220 Package: Structure and Features

The TO-220 package features a three-terminal design with a metal tab that serves as a heat sink, allowing efficient thermal dissipation for power transistors and voltage regulators. Its compact structure includes a plastic body encapsulating the semiconductor die, while the metal tab facilitates easy mounting to a heatsink or circuit board, enhancing reliability under high power conditions. You benefit from improved thermal management and mechanical stability when choosing TO-220 packaged devices for your electronics applications.

Thermal Performance Comparison

The Metal Can package offers superior thermal conductivity due to its metal casing, allowing for efficient heat dissipation in high-power applications. In contrast, the TO-220 package features a plastic body with an exposed metal tab that can be attached to a heatsink, providing effective but slightly lower thermal performance. Your choice between the two should consider the thermal resistance requirements and cooling solutions available for your specific electronic design.

Mechanical Robustness and Durability

Metal cans offer superior mechanical robustness and durability due to their hermetic sealing and rigid construction, making them highly resistant to environmental stress and physical damage. The TO-220 package prioritizes heat dissipation with its exposed metal tab, but its plastic encapsulation makes it less robust against mechanical impacts compared to metal cans. For applications demanding enhanced protection against mechanical stress, metal cans provide a more durable solution to safeguard your electronic components.

Electrical Performance Differences

Metal can packages offer superior thermal conductivity and lower thermal resistance compared to TO-220 packages, enhancing power dissipation and reliability under high-stress electrical conditions. The TO-220 package features higher parasitic inductance due to its larger lead frame, which can affect high-frequency switching performance negatively. Your choice between these packages impacts efficiency and thermal management in power electronics applications.

Applications and Use Cases

Metal can packages excel in high-reliability applications such as aerospace, military, and medical devices due to their superior thermal conductivity and robust hermetic sealing. TO-220 packages are widely used in power electronics, motor drivers, and voltage regulators because of their efficient heat dissipation and ease of mounting to heat sinks. Both packages serve distinct roles, with metal cans favored for durability in harsh environments and TO-220 preferred for cost-effective power semiconductor implementations.

Cost Considerations in Selection

Metal can packages generally offer superior thermal performance and reliability but come at a higher manufacturing cost due to complex hermetic sealing processes and expensive materials. TO-220 packages are more cost-effective and widely used in power electronics, providing a good balance between thermal management and affordability. Selecting between these packages often depends on budget constraints and application-specific thermal requirements, with TO-220 favored in mass production for its lower cost per unit.

Choosing the Right Package for Your Project

Metal can packages offer excellent thermal conductivity and durability, making them ideal for high-reliability applications and environments with extreme temperatures. TO-220 packages provide convenient mounting options, effective heat dissipation through external heatsinks, and compatibility with power transistors and regulators in medium-power circuits. Selecting the right package depends on project requirements such as thermal management, mechanical robustness, and ease of assembly.

Metal can vs TO-220 package Infographic

electrown.com

electrown.com