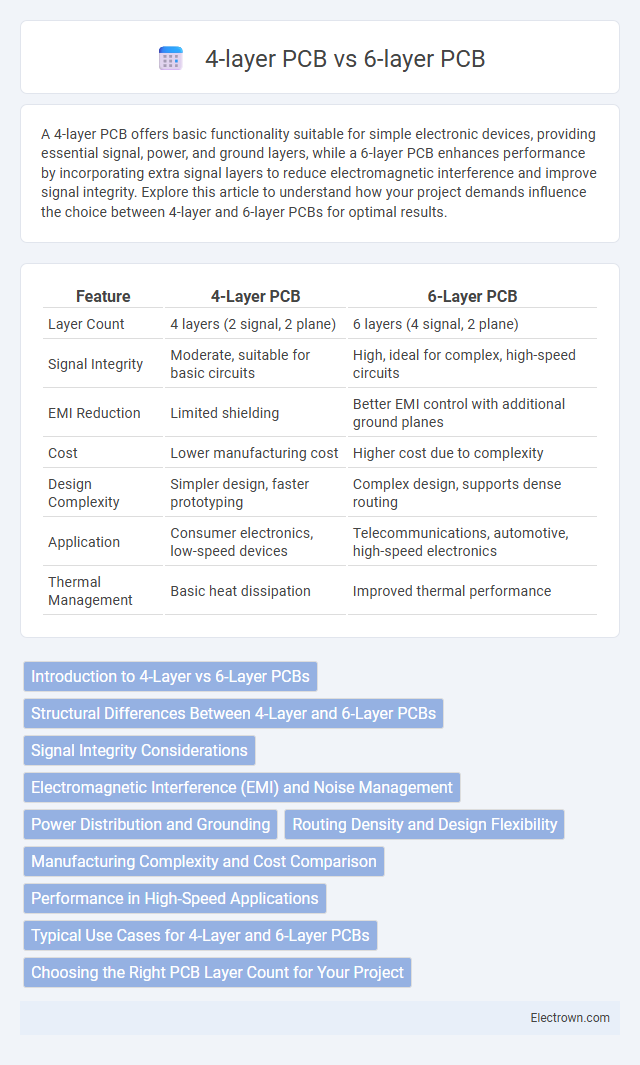

A 4-layer PCB offers basic functionality suitable for simple electronic devices, providing essential signal, power, and ground layers, while a 6-layer PCB enhances performance by incorporating extra signal layers to reduce electromagnetic interference and improve signal integrity. Explore this article to understand how your project demands influence the choice between 4-layer and 6-layer PCBs for optimal results.

Table of Comparison

| Feature | 4-Layer PCB | 6-Layer PCB |

|---|---|---|

| Layer Count | 4 layers (2 signal, 2 plane) | 6 layers (4 signal, 2 plane) |

| Signal Integrity | Moderate, suitable for basic circuits | High, ideal for complex, high-speed circuits |

| EMI Reduction | Limited shielding | Better EMI control with additional ground planes |

| Cost | Lower manufacturing cost | Higher cost due to complexity |

| Design Complexity | Simpler design, faster prototyping | Complex design, supports dense routing |

| Application | Consumer electronics, low-speed devices | Telecommunications, automotive, high-speed electronics |

| Thermal Management | Basic heat dissipation | Improved thermal performance |

Introduction to 4-Layer vs 6-Layer PCBs

A 4-layer PCB typically includes two signal layers, one power plane, and one ground plane, offering a balance between cost and electrical performance ideal for moderately complex circuits. A 6-layer PCB adds two additional layers, which enhances signal integrity, reduces electromagnetic interference, and supports higher-density designs suited for advanced electronics. Your choice between 4-layer and 6-layer PCBs depends on factors like signal complexity, noise reduction requirements, and overall device functionality.

Structural Differences Between 4-Layer and 6-Layer PCBs

4-layer PCBs consist of two signal layers, one power plane, and one ground plane, optimizing basic signal routing and power distribution. 6-layer PCBs add two extra signal layers or power/ground planes, enhancing signal integrity, electromagnetic interference (EMI) reduction, and power distribution for complex circuits. The additional layers in 6-layer PCBs support advanced designs requiring high-speed signal transmission and improved thermal management.

Signal Integrity Considerations

4-layer PCBs provide basic signal integrity by separating power and ground planes, reducing electromagnetic interference and crosstalk for moderate-speed circuits. 6-layer PCBs enhance signal integrity through additional dedicated layers for signal routing and power distribution, allowing improved impedance control and reduced noise in high-speed applications. You should choose a 6-layer PCB when your design demands stringent signal integrity for complex or high-frequency signals.

Electromagnetic Interference (EMI) and Noise Management

A 6-layer PCB offers superior Electromagnetic Interference (EMI) and noise management compared to a 4-layer PCB due to its additional dedicated ground and power planes that enhance signal integrity and reduce crosstalk. The extra layers allow for better shielding and separation of high-speed signals, minimizing electromagnetic emissions and susceptibility to external noise. Optimizing your design with a 6-layer PCB can significantly improve overall system performance by providing more effective EMI control and noise suppression.

Power Distribution and Grounding

A 6-layer PCB offers superior power distribution and grounding compared to a 4-layer PCB due to the additional internal planes dedicated to power and ground, reducing noise and improving signal integrity. With more layers, 6-layer PCBs provide better separation between signal and power layers, minimizing electromagnetic interference and voltage drops. Choosing a 6-layer PCB enhances Your device's overall performance by ensuring more stable and efficient power delivery and grounding.

Routing Density and Design Flexibility

A 6-layer PCB offers higher routing density compared to a 4-layer PCB, enabling more complex circuit designs within a compact footprint. The additional layers in a 6-layer board provide enhanced design flexibility by allowing separate planes for power, ground, and signal routing, reducing electromagnetic interference and crosstalk. In contrast, 4-layer PCBs have limited routing channels, often requiring more design compromises in high-density applications.

Manufacturing Complexity and Cost Comparison

4-layer PCBs involve fewer processing steps and less material usage, resulting in lower manufacturing complexity and cost compared to 6-layer PCBs. 6-layer PCBs require additional lamination cycles and precise layer alignment, increasing production time and expenses due to more intricate inner layer routing and enhanced signal integrity requirements. The added complexity in 6-layer PCB fabrication leads to higher costs, making 4-layer PCBs a more cost-effective option for simpler electronic designs.

Performance in High-Speed Applications

A 6-layer PCB provides superior performance in high-speed applications by offering enhanced signal integrity and reduced electromagnetic interference (EMI) through dedicated power and ground planes, which minimize crosstalk and noise. Compared to a 4-layer PCB, the additional layers in a 6-layer design enable better impedance control and more effective routing of high-frequency signals, ensuring reliable data transmission at greater speeds. Optimizing your PCB stack-up with 6 layers is crucial for complex, high-speed circuits that demand low signal distortion and improved thermal management.

Typical Use Cases for 4-Layer and 6-Layer PCBs

4-layer PCBs are typically used in moderately complex electronic devices such as power supplies, automotive control systems, and industrial machinery where signal integrity and reduced electromagnetic interference are important but not critical. 6-layer PCBs are preferred in advanced applications like high-speed communication equipment, aerospace, and sophisticated medical devices that require enhanced signal routing, superior power distribution, and optimal thermal management. Choosing between 4-layer and 6-layer PCB depends on your project's complexity, electromagnetic compatibility needs, and space constraints.

Choosing the Right PCB Layer Count for Your Project

Selecting the appropriate PCB layer count depends on factors like signal integrity, board size, and complexity. A 4-layer PCB offers a balance of cost-effectiveness and electrical performance with dedicated power and ground planes, making it suitable for moderately complex designs. For high-density circuits requiring improved EMI control, better signal routing, and enhanced power distribution, a 6-layer PCB provides additional layers for signal isolation and reduced crosstalk, ideal for advanced electronics and high-frequency applications.

4-layer PCB vs 6-layer PCB Infographic

electrown.com

electrown.com