PZT (lead zirconate titanate) offers superior piezoelectric properties and higher Curie temperature compared to BaTiO3 (barium titanate), making it more suitable for high-performance sensor and actuator applications. Explore the rest of the article to understand how your choice between these materials impacts device efficiency and durability.

Table of Comparison

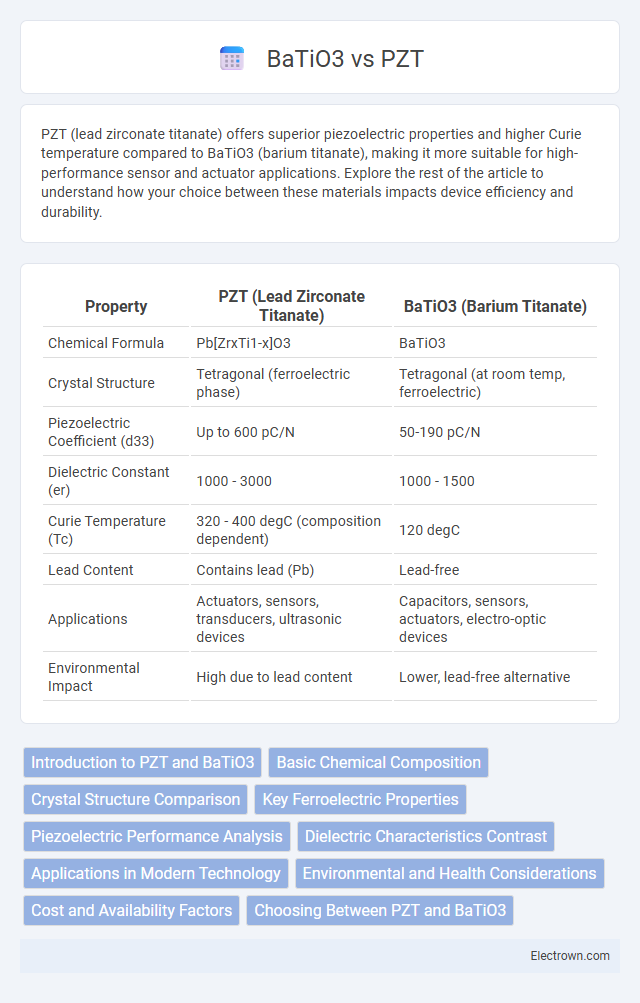

| Property | PZT (Lead Zirconate Titanate) | BaTiO3 (Barium Titanate) |

|---|---|---|

| Chemical Formula | Pb[ZrxTi1-x]O3 | BaTiO3 |

| Crystal Structure | Tetragonal (ferroelectric phase) | Tetragonal (at room temp, ferroelectric) |

| Piezoelectric Coefficient (d33) | Up to 600 pC/N | 50-190 pC/N |

| Dielectric Constant (er) | 1000 - 3000 | 1000 - 1500 |

| Curie Temperature (Tc) | 320 - 400 degC (composition dependent) | 120 degC |

| Lead Content | Contains lead (Pb) | Lead-free |

| Applications | Actuators, sensors, transducers, ultrasonic devices | Capacitors, sensors, actuators, electro-optic devices |

| Environmental Impact | High due to lead content | Lower, lead-free alternative |

Introduction to PZT and BaTiO3

PZT (lead zirconate titanate) and BaTiO3 (barium titanate) are prominent ferroelectric ceramics widely used in electronic components such as sensors, actuators, and capacitors. PZT is known for its superior piezoelectric properties and higher Curie temperature, making it suitable for high-performance applications. BaTiO3, a classic ferroelectric material, exhibits strong dielectric properties and is often favored for cost-effective and environmentally friendly solutions.

Basic Chemical Composition

PZT (lead zirconate titanate) is a solid solution of lead zirconate (PbZrO3) and lead titanate (PbTiO3), characterized by the presence of lead (Pb), zirconium (Zr), titanium (Ti), and oxygen (O) in its perovskite crystal structure. BaTiO3 (barium titanate) consists of barium (Ba), titanium (Ti), and oxygen (O) atoms, forming a similar perovskite structure but without lead and zirconium components. The presence of lead in PZT contributes to its higher piezoelectric and ferroelectric properties compared to BaTiO3, which is lead-free and environmentally safer but generally exhibits lower electromechanical performance.

Crystal Structure Comparison

PZT (lead zirconate titanate) exhibits a perovskite crystal structure similar to BaTiO3 (barium titanate) but with a more complex composition due to the substitution of lead and zirconium ions which enhance ferroelectric properties. Unlike BaTiO3, which undergoes well-defined phase transitions (cubic to tetragonal to orthorhombic), PZT's structure can be tuned by varying Zr/Ti ratios, allowing tailored ferroelectric and piezoelectric responses. Your choice between PZT and BaTiO3 should consider the distinct phase stability and structural versatility, impacting the material's electrical and mechanical performance.

Key Ferroelectric Properties

PZT (lead zirconate titanate) exhibits higher piezoelectric coefficients and greater Curie temperature compared to BaTiO3 (barium titanate), making it more suitable for high-performance ferroelectric applications. BaTiO3 offers excellent dielectric properties and a well-defined phase transition near room temperature, which is beneficial for capacitors and sensors operating at standard conditions. Your choice between PZT and BaTiO3 should depend on specific application requirements such as temperature stability, piezoelectric response, and environmental considerations.

Piezoelectric Performance Analysis

PZT (lead zirconate titanate) exhibits superior piezoelectric coefficients (d33 up to 600 pC/N) compared to BaTiO3 (around 190 pC/N), making PZT the preferred choice for high-performance actuators and sensors. The higher Curie temperature of PZT (approximately 350degC) versus BaTiO3 (~120degC) ensures greater thermal stability in piezoelectric applications. BaTiO3 remains favorable in lead-free and environmentally friendly designs despite its lower piezoelectric response and lower mechanical quality factor.

Dielectric Characteristics Contrast

PZT (Lead Zirconate Titanate) exhibits significantly higher dielectric constants compared to BaTiO3 (Barium Titanate), making it more effective for high-capacitance applications. BaTiO3 offers lower dielectric loss and better temperature stability, which is advantageous for sensors and actuators operating in varying conditions. Your choice between these materials depends on whether you prioritize maximum dielectric response or consistent performance across temperature ranges.

Applications in Modern Technology

PZT (lead zirconate titanate) and BaTiO3 (barium titanate) are extensively used in modern technology for their ferroelectric and piezoelectric properties. PZT is predominantly applied in precision actuators, ultrasonic transducers, and ferroelectric memory devices due to its superior piezoelectric coefficients and temperature stability. BaTiO3 finds applications in capacitors, thermistors, and electro-optic devices where its high dielectric constant and tunability are critical.

Environmental and Health Considerations

PZT (lead zirconate titanate) contains lead, posing significant environmental and health risks due to its toxicity and potential for bioaccumulation. BaTiO3 (barium titanate) offers a safer alternative with no lead content, reducing hazardous waste concerns and lowering health hazards associated with exposure. Regulatory restrictions on lead-based materials have accelerated the shift toward BaTiO3 in eco-friendly and biocompatible applications.

Cost and Availability Factors

PZT (lead zirconate titanate) generally offers higher performance but comes at a higher cost due to lead content and complex manufacturing processes, making it less environmentally favorable. BaTiO3 (barium titanate) is more economically viable and widely available because of its lead-free composition and simpler synthesis methods, leading to lower production expenses. Market demand for lead-free materials further improves BaTiO3's accessibility and cost efficiency in commercial applications.

Choosing Between PZT and BaTiO3

Choosing between PZT (lead zirconate titanate) and BaTiO3 (barium titanate) depends on your application's performance and environmental needs. PZT offers higher piezoelectric coefficients and temperature stability, making it ideal for precision sensors and actuators. BaTiO3 is lead-free and environmentally friendly, suitable for low-cost capacitors and devices requiring non-toxic materials.

PZT vs BaTiO3 Infographic

electrown.com

electrown.com