VCSELs (Vertical-Cavity Surface-Emitting Lasers) offer advantages in manufacturing cost, power efficiency, and easier integration due to their surface-emitting design, while edge-emitting lasers provide higher output power and better beam quality for long-distance communication. Understanding these differences can help you choose the right laser type for your specific optical application needs; read on to explore their detailed performance characteristics and use cases.

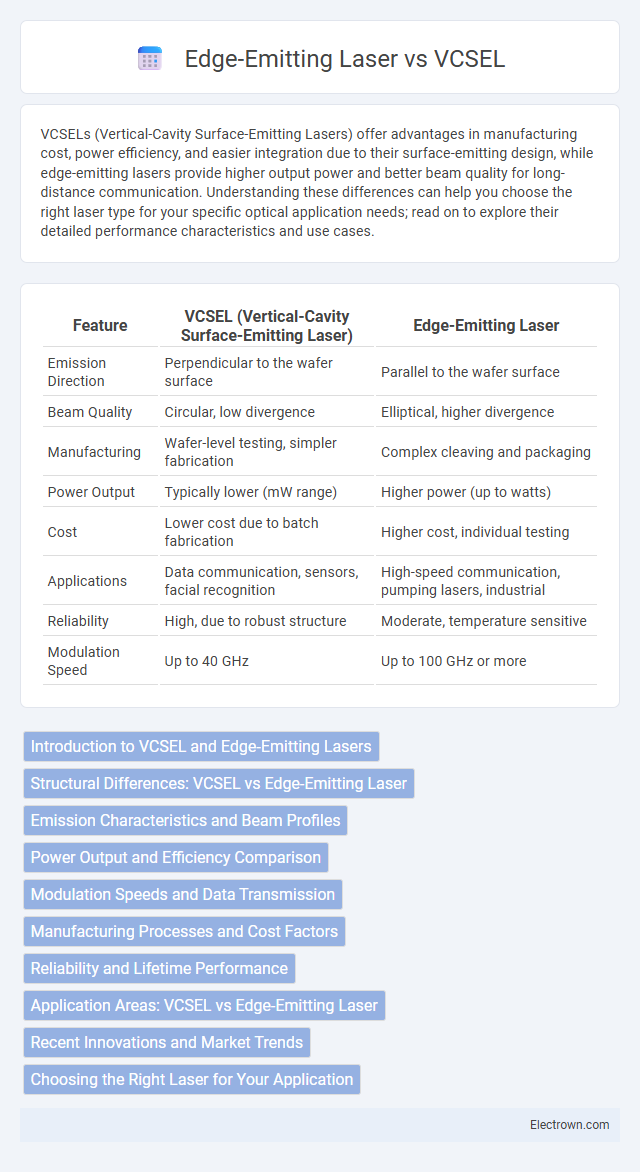

Table of Comparison

| Feature | VCSEL (Vertical-Cavity Surface-Emitting Laser) | Edge-Emitting Laser |

|---|---|---|

| Emission Direction | Perpendicular to the wafer surface | Parallel to the wafer surface |

| Beam Quality | Circular, low divergence | Elliptical, higher divergence |

| Manufacturing | Wafer-level testing, simpler fabrication | Complex cleaving and packaging |

| Power Output | Typically lower (mW range) | Higher power (up to watts) |

| Cost | Lower cost due to batch fabrication | Higher cost, individual testing |

| Applications | Data communication, sensors, facial recognition | High-speed communication, pumping lasers, industrial |

| Reliability | High, due to robust structure | Moderate, temperature sensitive |

| Modulation Speed | Up to 40 GHz | Up to 100 GHz or more |

Introduction to VCSEL and Edge-Emitting Lasers

VCSELs (Vertical-Cavity Surface-Emitting Lasers) emit light perpendicular to the wafer surface, offering advantages in manufacturing scalability and low power consumption compared to edge-emitting lasers, which emit light from the wafer edge and are commonly used for high-power applications. Edge-emitting lasers provide higher output power and longer reach, making them suitable for telecommunications and industrial uses. Your choice depends on application requirements for efficiency, power, and integration density.

Structural Differences: VCSEL vs Edge-Emitting Laser

VCSELs (Vertical-Cavity Surface-Emitting Lasers) feature a vertical emission structure with light emitted perpendicular to the wafer surface, utilizing short cavity lengths and distributed Bragg reflectors (DBRs) as mirrors. In contrast, edge-emitting lasers emit light horizontally from the chip edge, employing longer cavity lengths with cleaved facets acting as mirrors. The vertical cavity structure in VCSELs enables easier testing and integration into arrays, while the horizontal cavity in edge-emitters supports higher output power and narrower beam divergence.

Emission Characteristics and Beam Profiles

VCSELs (Vertical-Cavity Surface-Emitting Lasers) emit laser light perpendicular to the wafer surface, producing a circular, low-divergence beam with a symmetric Gaussian intensity profile ideal for fiber coupling and free-space optical applications. In contrast, edge-emitting lasers emit light parallel to the wafer surface with an elliptical beam profile exhibiting higher divergence in the vertical direction due to the asymmetric waveguide structure, resulting in more complex beam shaping requirements. The inherent emission characteristics of VCSELs allow for easier array integration and uniform beam quality, whereas edge-emitters typically offer higher output power but require advanced optics for beam collimation.

Power Output and Efficiency Comparison

VCSELs typically offer lower power output compared to edge-emitting lasers, making them ideal for short-range communication and sensing applications where efficiency and size are critical. Edge-emitting lasers deliver higher power levels with better beam quality, suitable for long-distance fiber optic communication and high-performance industrial uses. Your choice between these laser types depends on the specific power and efficiency requirements of your application.

Modulation Speeds and Data Transmission

VCSELs achieve higher modulation speeds up to 50 GHz, enabling faster data transmission for short-reach optical communication, while edge-emitting lasers typically operate below 40 GHz but excel in long-distance applications. Your choice depends on whether low power consumption and integration in data centers outweigh the need for greater output power and longer reach. VCSELs offer superior efficiency and simplified testing, making them ideal for high-speed, short-distance data links.

Manufacturing Processes and Cost Factors

VCSELs (Vertical-Cavity Surface-Emitting Lasers) benefit from wafer-level fabrication techniques that enable lower manufacturing costs and higher production yield compared to edge-emitting lasers, which require complex cleaving and coating steps. The simpler VCSEL structure allows for easier integration and testing on the wafer, reducing assembly time and cost per unit. When considering your application, VCSELs often provide a cost-effective solution, especially for high-volume manufacturing.

Reliability and Lifetime Performance

VCSELs (Vertical-Cavity Surface-Emitting Lasers) demonstrate superior reliability and longer lifetime performance compared to edge-emitting lasers due to their simpler construction and lower operating current densities. The vertical emission design of VCSELs reduces thermal stress and degradation, resulting in stable output power over extended periods. Edge-emitting lasers, while capable of higher power, typically experience higher failure rates due to increased susceptibility to facet damage and thermal effects.

Application Areas: VCSEL vs Edge-Emitting Laser

VCSELs excel in data communication, optical mice, and 3D sensing due to their low power consumption, high modulation speeds, and ease of array fabrication. Edge-emitting lasers are preferred in long-haul fiber optic communications and industrial applications that demand high output power and narrow spectral linewidth. The choice between VCSEL and edge-emitting laser depends on specific requirements like power, beam quality, and integration flexibility in applications such as telecommunications, sensing, and consumer electronics.

Recent Innovations and Market Trends

Recent innovations in VCSEL technology have focused on enhancing energy efficiency, miniaturization, and integration with 3D sensing applications, driving significant growth in sectors like automotive, consumer electronics, and data communications. Edge-emitting lasers continue to evolve with advancements in high-power output and wavelength tunability, supporting expanding markets in industrial manufacturing, telecommunications, and medical diagnostics. Market trends indicate a robust shift towards VCSEL adoption due to lower production costs and improved performance at short-range optical sensing, while edge-emitters maintain dominance in long-distance, high-power laser applications.

Choosing the Right Laser for Your Application

VCSELs offer advantages such as lower power consumption, easier fabrication, and superior beam quality, making them ideal for short-distance optical communication and sensing applications. Edge-emitting lasers provide higher output power and better performance in long-distance fiber optic communications and high-speed data transmission. Your choice between VCSEL and edge-emitting laser depends on factors like required power, application range, and cost efficiency.

VCSEL vs edge-emitting laser Infographic

electrown.com

electrown.com