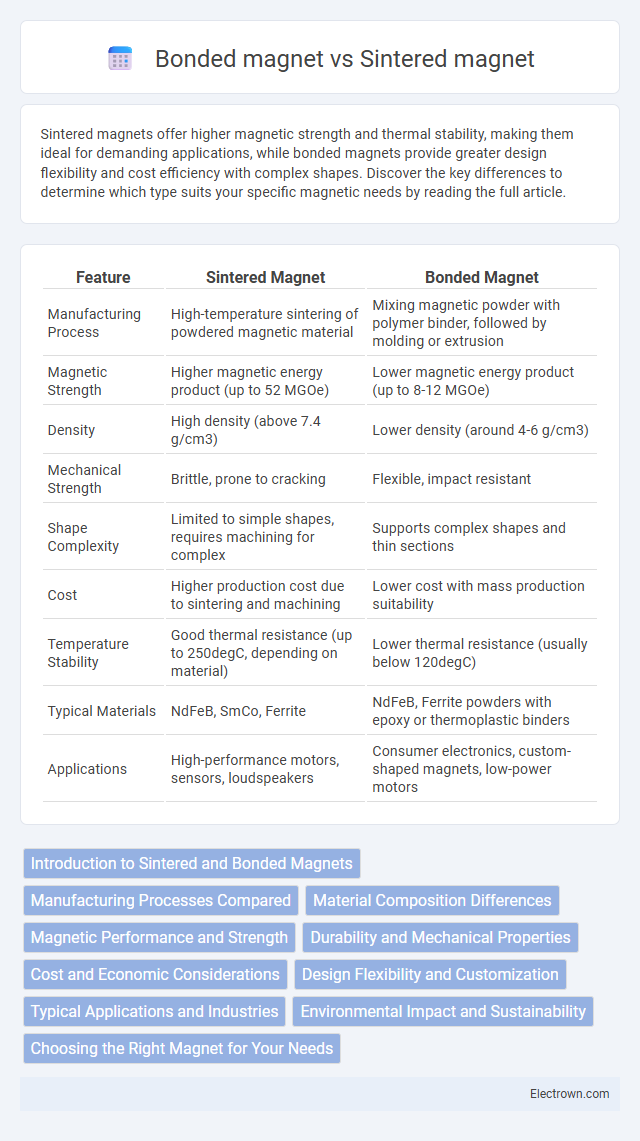

Sintered magnets offer higher magnetic strength and thermal stability, making them ideal for demanding applications, while bonded magnets provide greater design flexibility and cost efficiency with complex shapes. Discover the key differences to determine which type suits your specific magnetic needs by reading the full article.

Table of Comparison

| Feature | Sintered Magnet | Bonded Magnet |

|---|---|---|

| Manufacturing Process | High-temperature sintering of powdered magnetic material | Mixing magnetic powder with polymer binder, followed by molding or extrusion |

| Magnetic Strength | Higher magnetic energy product (up to 52 MGOe) | Lower magnetic energy product (up to 8-12 MGOe) |

| Density | High density (above 7.4 g/cm3) | Lower density (around 4-6 g/cm3) |

| Mechanical Strength | Brittle, prone to cracking | Flexible, impact resistant |

| Shape Complexity | Limited to simple shapes, requires machining for complex | Supports complex shapes and thin sections |

| Cost | Higher production cost due to sintering and machining | Lower cost with mass production suitability |

| Temperature Stability | Good thermal resistance (up to 250degC, depending on material) | Lower thermal resistance (usually below 120degC) |

| Typical Materials | NdFeB, SmCo, Ferrite | NdFeB, Ferrite powders with epoxy or thermoplastic binders |

| Applications | High-performance motors, sensors, loudspeakers | Consumer electronics, custom-shaped magnets, low-power motors |

Introduction to Sintered and Bonded Magnets

Sintered magnets are produced by compacting and heating powdered magnetic materials at high temperatures, resulting in dense, high-performance magnets with superior magnetic strength and temperature resistance. Bonded magnets are created by mixing magnetic powders with a binding resin, then molding them into shape, offering design flexibility and cost-effective production but lower magnetic power compared to sintered types. Your choice between sintered and bonded magnets depends on the application's performance requirements and manufacturing constraints.

Manufacturing Processes Compared

Sintered magnets undergo a high-temperature pressing and heating process that compacts powdered magnetic material into dense, highly magnetic components with superior strength and thermal resistance. Bonded magnets combine magnetic powders with a polymer binder, typically shaped through injection molding or compression, allowing complex geometries and lightweight parts at lower production costs but with reduced magnetic performance. The key manufacturing differences influence mechanical properties, magnet strength, and application suitability, with sintered magnets excelling in high-performance environments and bonded magnets preferred for flexibility and cost efficiency.

Material Composition Differences

Sintered magnets are composed primarily of compacted and heated rare earth powders, such as neodymium, iron, and boron, resulting in high magnetic strength and density. Bonded magnets combine magnetic powders with polymer binders like rubber or thermoplastics, offering flexibility and varied shapes but lower magnetic performance. Your choice depends on whether you prioritize magnetic power or design versatility based on these distinct material compositions.

Magnetic Performance and Strength

Sintered magnets exhibit superior magnetic performance and higher coercivity due to their dense microstructure, allowing for stronger magnetic fields and enhanced temperature stability. Bonded magnets, made by mixing magnetic powders with a polymer binder, offer lower magnetic strength but enable intricate shapes and better mechanical flexibility. While sintered magnets are ideal for high-performance applications requiring maximum magnetic flux, bonded magnets provide versatility where weight and design complexity are critical.

Durability and Mechanical Properties

Sintered magnets exhibit superior durability and mechanical strength due to their dense microstructure formed under high temperature and pressure, making them resistant to cracking and chipping. Bonded magnets, created by mixing magnetic powders with a polymer binder, offer lower mechanical toughness but provide flexibility and easier shaping options. Your choice depends on whether you prioritize structural integrity or design versatility in demanding applications.

Cost and Economic Considerations

Sintered magnets typically exhibit higher production costs due to energy-intensive manufacturing processes and the need for high-temperature sintering equipment, making them more expensive than bonded magnets. Bonded magnets, produced through powder injection molding or compression bonding, allow for lower manufacturing costs and improved material utilization, which enhances economic feasibility for large-scale applications. Cost-effectiveness in magnet selection depends on volume requirements, with bonded magnets favored for complex shapes and low-to-medium performance needs, while sintered magnets justify their cost in high-performance applications demanding superior magnetic properties.

Design Flexibility and Customization

Sintered magnets offer limited design flexibility due to their rigid manufacturing process, which restricts complex shapes and fine tolerances. Bonded magnets provide greater customization options, allowing intricate geometries and precise dimensions through injection molding or compression bonding techniques. This design adaptability makes bonded magnets ideal for applications requiring complex profiles and tight design specifications.

Typical Applications and Industries

Sintered magnets are widely used in high-performance applications such as electric vehicle motors, wind turbine generators, and aerospace components due to their superior magnetic strength and temperature resistance. Bonded magnets find typical applications in consumer electronics, sensors, and small motors where complex shapes and precision are required without compromising manufacturing efficiency. The automotive, renewable energy, and electronics industries heavily rely on sintered magnets, while bonded magnets are preferred in telecommunications, medical devices, and office equipment sectors.

Environmental Impact and Sustainability

Sintered magnets have a higher environmental impact due to energy-intensive manufacturing processes and the use of rare earth elements, leading to resource depletion and complex recycling challenges. Bonded magnets, produced with lower energy consumption and enabling easier recycling due to their polymer matrix, offer a more sustainable alternative with reduced carbon footprint. When selecting your magnet type, consider bonded magnets for eco-friendly applications prioritizing sustainability and resource conservation.

Choosing the Right Magnet for Your Needs

Sintered magnets offer higher magnetic strength and temperature resistance, making them ideal for applications requiring strong, durable performance. Bonded magnets provide greater design flexibility and complex shapes at a lower cost, suitable for precision or lightweight needs. Your choice depends on balancing performance requirements with manufacturing constraints and budget.

Sintered magnet vs Bonded magnet Infographic

electrown.com

electrown.com