SMD crystals offer higher frequency stability and precision compared to ceramic resonators, making them ideal for applications requiring accurate timing and lower frequency drift. Explore the rest of the article to understand which component suits your project's performance and cost requirements best.

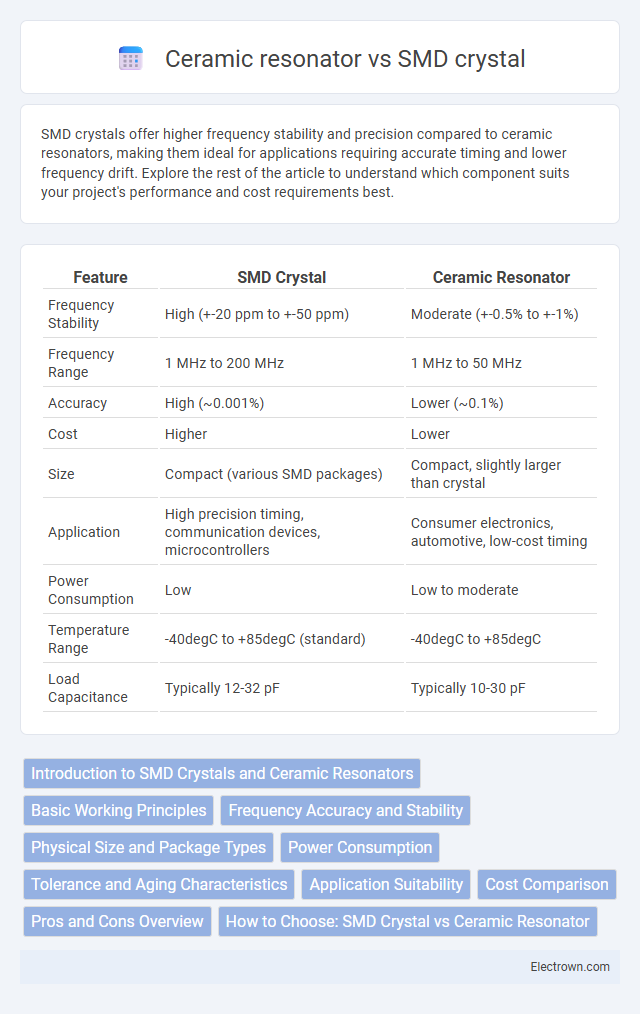

Table of Comparison

| Feature | SMD Crystal | Ceramic Resonator |

|---|---|---|

| Frequency Stability | High (+-20 ppm to +-50 ppm) | Moderate (+-0.5% to +-1%) |

| Frequency Range | 1 MHz to 200 MHz | 1 MHz to 50 MHz |

| Accuracy | High (~0.001%) | Lower (~0.1%) |

| Cost | Higher | Lower |

| Size | Compact (various SMD packages) | Compact, slightly larger than crystal |

| Application | High precision timing, communication devices, microcontrollers | Consumer electronics, automotive, low-cost timing |

| Power Consumption | Low | Low to moderate |

| Temperature Range | -40degC to +85degC (standard) | -40degC to +85degC |

| Load Capacitance | Typically 12-32 pF | Typically 10-30 pF |

Introduction to SMD Crystals and Ceramic Resonators

SMD crystals are precise frequency control components offering high stability and low phase noise, commonly used in microcontroller clock circuits. Ceramic resonators provide a cost-effective alternative with moderate frequency stability and faster start-up times, often utilized in less demanding applications. Both SMD crystals and ceramic resonators serve as vital timing elements in electronic devices, balancing performance and cost based on specific circuit requirements.

Basic Working Principles

SMD crystals operate by utilizing the piezoelectric effect in quartz to generate precise oscillations with a fixed resonant frequency, ensuring high frequency stability. Ceramic resonators function through the mechanical vibrations of a piezoelectric ceramic material, providing moderate frequency accuracy suitable for less demanding applications. Both components serve as timing elements in electronic circuits but differ significantly in signal purity and frequency precision.

Frequency Accuracy and Stability

SMD crystals offer superior frequency accuracy and long-term stability compared to ceramic resonators due to their precise quartz crystal structure and minimal frequency drift over temperature variations. Ceramic resonators typically exhibit wider frequency tolerance and reduced stability, making them less suitable for applications requiring high precision timing. Choosing an SMD crystal ensures your device maintains consistent performance in environments demanding reliable frequency control.

Physical Size and Package Types

SMD crystals typically feature compact rectangular packages like 2.0x1.2mm or 3.2x2.5mm, offering precise frequency stability in a minimized footprint suitable for high-density PCB layouts. Ceramic resonators are usually available in slightly larger SMD packages, often around 4.0x3.2mm, with fewer package variations but benefit from lower cost and simpler manufacturing. The smaller physical size and standardized package types of SMD crystals make them ideal for applications demanding high frequency accuracy and space efficiency.

Power Consumption

SMD crystals typically consume less power compared to ceramic resonators, making them more suitable for low-power applications and battery-operated devices. The higher Q-factor of SMD crystals contributes to their energy efficiency by maintaining stable oscillations with minimal input energy. Ceramic resonators, while cost-effective and compact, generally require more power due to their lower Q-factor and higher equivalent series resistance.

Tolerance and Aging Characteristics

SMD crystals offer superior frequency stability with tolerance as low as +-10 ppm and minimal aging effects typically around +-1 ppm per year. Ceramic resonators, while more cost-effective, have wider tolerance ranges from +-0.5% to +-2% and higher aging rates, often up to +-0.1% annually. Your choice between these components should consider the precision requirements and long-term stability of your electronic application.

Application Suitability

SMD crystals offer superior frequency stability and precision, making them ideal for high-performance applications like microcontrollers, RF circuits, and communication devices requiring accurate timing. Ceramic resonators provide a cost-effective solution with smaller size and moderate frequency stability, suitable for consumer electronics, toys, and less critical timing applications. Selection depends on the required frequency accuracy, operating environment, and budget constraints in electronic circuit design.

Cost Comparison

SMD crystals generally have a higher cost compared to ceramic resonators due to their superior frequency stability and precision in electronic circuits. Ceramic resonators offer a more budget-friendly alternative with acceptable performance for less critical timing applications. Your choice depends on the balance between cost efficiency and the required accuracy in your electronic design.

Pros and Cons Overview

SMD crystals offer high frequency stability and low phase noise, making them ideal for precision timing applications, but they tend to be more expensive and sensitive to mechanical stress. Ceramic resonators provide better vibration resistance and cost efficiency, suitable for less critical frequency control tasks, yet they suffer from higher frequency tolerance and aging drift. Selecting between them depends on balancing precision requirements against environmental durability and budget constraints.

How to Choose: SMD Crystal vs Ceramic Resonator

Choosing between an SMD crystal and a ceramic resonator depends on your application's frequency stability and accuracy requirements. SMD crystals offer superior frequency precision, low phase noise, and better aging characteristics, making them ideal for high-performance circuits needing tight tolerances. Ceramic resonators provide cost-effective solutions with moderate stability and are suitable for less critical timing applications where size and budget constraints dominate.

SMD crystal vs Ceramic resonator Infographic

electrown.com

electrown.com