Pyrex glass, originally made from borosilicate, has shifted to soda-lime glass in some regions, offering less thermal shock resistance but increased affordability. Understanding the differences between Pyrex and borosilicate glass can help you choose the best option for your kitchen needs, so continue reading to learn more.

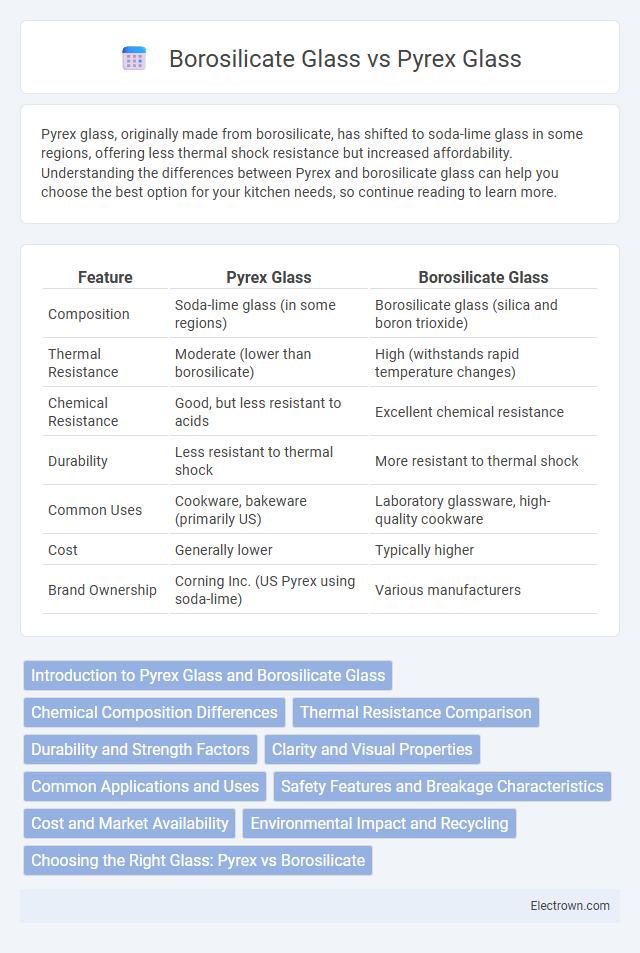

Table of Comparison

| Feature | Pyrex Glass | Borosilicate Glass |

|---|---|---|

| Composition | Soda-lime glass (in some regions) | Borosilicate glass (silica and boron trioxide) |

| Thermal Resistance | Moderate (lower than borosilicate) | High (withstands rapid temperature changes) |

| Chemical Resistance | Good, but less resistant to acids | Excellent chemical resistance |

| Durability | Less resistant to thermal shock | More resistant to thermal shock |

| Common Uses | Cookware, bakeware (primarily US) | Laboratory glassware, high-quality cookware |

| Cost | Generally lower | Typically higher |

| Brand Ownership | Corning Inc. (US Pyrex using soda-lime) | Various manufacturers |

Introduction to Pyrex Glass and Borosilicate Glass

Pyrex glass originally referred to soda-lime glass but has evolved to commonly denote borosilicate glass, valued for its thermal resistance and durability in kitchenware. Borosilicate glass contains approximately 12-13% boron oxide, giving it exceptional resistance to thermal shock and chemical corrosion. Your choice between Pyrex and borosilicate glass impacts cookware performance, especially for high-temperature and rapid temperature change applications.

Chemical Composition Differences

Pyrex glass originally consisted of borosilicate glass, containing about 80% silica and 13% boron oxide, which provides excellent thermal resistance and durability. However, modern Pyrex produced in the U.S. primarily uses soda-lime glass, characterized by higher sodium oxide and calcium oxide content, reducing its thermal shock resistance compared to traditional borosilicate. The chemical composition differences between classic borosilicate and soda-lime Pyrex significantly impact their thermal expansion coefficients and overall performance in high-temperature applications.

Thermal Resistance Comparison

Borosilicate glass offers superior thermal resistance, tolerating rapid temperature changes up to 450degC without cracking, making it ideal for high-heat applications. Traditional Pyrex glass, originally made from borosilicate but now often soda-lime glass in some regions, typically withstands lower thermal stress, around 120degC to 150degC before risk of breakage increases. Choosing borosilicate glass enhances the durability and safety of your cookware or laboratory equipment under intense heat fluctuations.

Durability and Strength Factors

Pyrex glass and borosilicate glass differ significantly in durability and strength factors; borosilicate glass offers superior thermal resistance and is less prone to cracking under sudden temperature changes due to its low thermal expansion coefficient. Pyrex glass, originally made from borosilicate but now often soda-lime glass in some regions, is more affordable but less resistant to thermal shock, affecting its longevity in extreme conditions. Understanding these differences ensures you select the right glass type for applications requiring high durability and strength.

Clarity and Visual Properties

Pyrex glass, primarily made from tempered soda-lime glass, offers excellent clarity and a transparent appearance ideal for everyday kitchen use. Borosilicate glass contains silica and boron trioxide, providing superior thermal resistance and maintaining optical clarity without discoloration under high heat. The visual properties of Borosilicate glass remain consistent even during rapid temperature changes, making it preferred for laboratory and premium cookware applications.

Common Applications and Uses

Pyrex glass is commonly used in kitchenware such as baking dishes, measuring cups, and storage containers due to its excellent thermal shock resistance and durability. Borosilicate glass, known for its superior heat resistance and chemical stability, is frequently utilized in laboratory equipment, scientific glassware, and high-performance cookware. Your choice between Pyrex and borosilicate glass depends on whether you need everyday kitchen functionality or specialized applications requiring enhanced thermal and chemical resilience.

Safety Features and Breakage Characteristics

Pyrex glass, originally made from borosilicate, is renowned for its excellent thermal shock resistance, making it less prone to shattering when exposed to rapid temperature changes, while modern Pyrex in the U.S. is often tempered soda-lime glass, which breaks into safer, smaller pieces. Borosilicate glass offers superior chemical stability and durability against thermal stress, significantly reducing the risk of breakage under extreme cooking conditions and providing enhanced safety for your kitchen. Your choice between these materials should consider their differing breakage patterns and resistance to thermal shock to ensure optimal safety during use.

Cost and Market Availability

Borosilicate glass generally has a higher cost due to its superior thermal shock resistance and durability, making it a preferred choice for laboratory equipment and high-end cookware. Pyrex glass, commonly available as soda-lime glass in many markets, is more affordable and widely accessible but less resistant to temperature extremes. Your choice depends on whether cost-efficiency or performance reliability is the primary factor for your application.

Environmental Impact and Recycling

Borosilicate glass has a lower environmental impact due to its durability and resistance to thermal shock, reducing the frequency of replacement and waste generation compared to standard Pyrex glass, which originally was soda-lime glass. Recycling borosilicate glass is more challenging because of its higher melting point, requiring specialized facilities, whereas traditional Pyrex soda-lime glass can be recycled more easily in standard glass recycling streams. However, advancements in recycling technology are improving the feasibility of borosilicate glass reuse, promoting sustainability in laboratory and kitchenware applications.

Choosing the Right Glass: Pyrex vs Borosilicate

Pyrex glass, originally made from borosilicate, now typically uses soda-lime glass in the U.S., offering affordability but less thermal resistance compared to true borosilicate glass known for its superior durability and resistance to thermal shock. When choosing the right glass, consider that borosilicate glass maintains stability at temperatures up to 450degC and withstands rapid temperature changes, making it ideal for laboratory use and precise cooking. Your decision hinges on whether you prioritize cost-effectiveness with everyday kitchen use or high-performance thermal resistance for scientific or specialized culinary needs.

Pyrex glass vs Borosilicate glass Infographic

electrown.com

electrown.com