SnPb solder offers superior wetting properties and lower melting points compared to lead-free solder, making it a preferred choice for certain precision electronics. Understanding the differences and applications of each can help you make informed decisions for your soldering needs--read on to explore their advantages and limitations in detail.

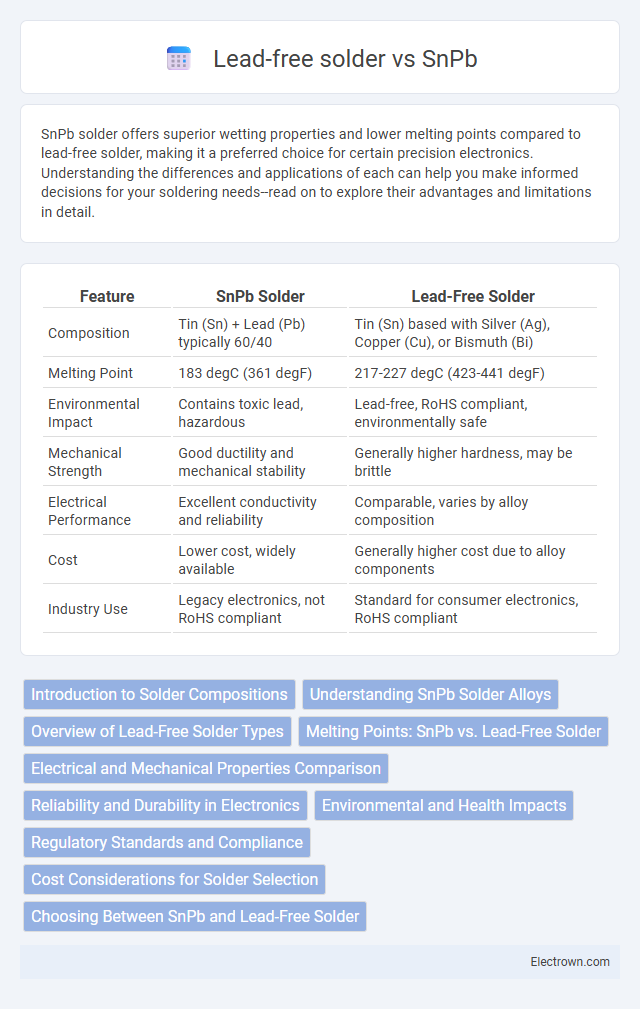

Table of Comparison

| Feature | SnPb Solder | Lead-Free Solder |

|---|---|---|

| Composition | Tin (Sn) + Lead (Pb) typically 60/40 | Tin (Sn) based with Silver (Ag), Copper (Cu), or Bismuth (Bi) |

| Melting Point | 183 degC (361 degF) | 217-227 degC (423-441 degF) |

| Environmental Impact | Contains toxic lead, hazardous | Lead-free, RoHS compliant, environmentally safe |

| Mechanical Strength | Good ductility and mechanical stability | Generally higher hardness, may be brittle |

| Electrical Performance | Excellent conductivity and reliability | Comparable, varies by alloy composition |

| Cost | Lower cost, widely available | Generally higher cost due to alloy components |

| Industry Use | Legacy electronics, not RoHS compliant | Standard for consumer electronics, RoHS compliant |

Introduction to Solder Compositions

SnPb solder, composed primarily of tin (Sn) and lead (Pb), offers low melting points around 183degC and excellent wettability, making it ideal for traditional electronic soldering applications. Lead-free solder alternatives, often based on tin combined with silver, copper, or bismuth, provide enhanced environmental safety and compliance with regulations like RoHS but typically require higher melting temperatures between 217degC and 240degC. Understanding the specific alloy compositions helps you select the optimal solder type for reliability, mechanical strength, and environmental requirements in your manufacturing processes.

Understanding SnPb Solder Alloys

SnPb solder alloys, primarily composed of tin (Sn) and lead (Pb), offer superior wetting properties and a lower melting point around 183degC, facilitating reliable mechanical and electrical connections in electronic assemblies. These alloys remain preferred in certain applications due to their excellent thermal fatigue resistance and ease of rework compared to lead-free alternatives. Understanding the composition and performance characteristics of SnPb solder is crucial for selecting the optimal soldering material for your manufacturing and repair processes.

Overview of Lead-Free Solder Types

Lead-free solder primarily consists of tin (Sn) combined with metals like silver (Ag), copper (Cu), and sometimes bismuth (Bi) or indium (In), offering an environmentally friendly alternative to traditional SnPb solder. Common lead-free solder alloys include SAC305 (96.5% Sn, 3.0% Ag, 0.5% Cu) and SnCu-based alloys, which deliver excellent mechanical strength and thermal reliability for electronic assemblies. Your choice between SnPb and lead-free solder affects assembly processes and compliance with regulations such as RoHS, requiring a balance between solderability, melting point, and performance.

Melting Points: SnPb vs. Lead-Free Solder

SnPb solder typically has a melting point around 183degC, offering lower melting temperatures that facilitate easier soldering processes. Lead-free solders, composed mainly of tin with additions like silver and copper, have higher melting points ranging from 217degC to 227degC, which requires more heat during soldering. The increased melting temperature of lead-free solder affects component stress and solder joint reliability in electronic manufacturing.

Electrical and Mechanical Properties Comparison

SnPb solder offers superior electrical conductivity and lower melting points, making it ideal for high-reliability electrical connections. Lead-free solder, typically composed of SnAgCu alloys, exhibits higher melting points and slightly reduced electrical conductivity but provides improved mechanical strength and environmental compliance. Your choice between SnPb and lead-free solder should balance electrical performance with mechanical durability and regulatory requirements.

Reliability and Durability in Electronics

SnPb solder offers superior reliability and durability in electronics due to its well-established melting point and consistent mechanical strength, making it highly effective in withstanding thermal cycling and mechanical stress. Lead-free solder, typically composed of tin, silver, and copper (SAC alloys), provides enhanced environmental safety but can present challenges in long-term reliability, including increased brittleness and susceptibility to thermal fatigue. Selecting the right solder for your electronics depends on balancing regulatory compliance with performance requirements, especially in mission-critical applications.

Environmental and Health Impacts

SnPb solder contains lead, a toxic metal linked to neurological damage and environmental contamination, making it hazardous during manufacturing and disposal. Lead-free solder alternatives, composed mainly of tin, silver, and copper, reduce these health risks and minimize soil and water pollution. Choosing lead-free solder supports safer working conditions and aligns with environmental regulations to protect your health and the ecosystem.

Regulatory Standards and Compliance

SnPb solder remains widely regulated under standards like RoHS Exemption 7c-1, permitting its use in specific electronics due to its superior mechanical properties and reliability. Lead-free solder, often composed of SAC alloys (tin-silver-copper), strictly complies with global mandates such as the European Union's Restriction of Hazardous Substances Directive (RoHS) and the WEEE directive, driving widespread adoption in consumer electronics. Manufacturers must ensure solder materials meet regional compliance requirements to avoid legal penalties and support environmental sustainability initiatives.

Cost Considerations for Solder Selection

SnPb solder typically offers lower upfront costs due to its well-established manufacturing processes and widespread availability of raw materials. Lead-free solder, while generally more expensive, presents potential savings over time by meeting regulatory requirements like RoHS and reducing environmental disposal fees. Your choice should balance initial material expenses with compliance-related cost benefits to optimize total expenditure.

Choosing Between SnPb and Lead-Free Solder

Choosing between SnPb (tin-lead) and lead-free solder depends on your project's specific requirements for reliability, environmental compliance, and performance. SnPb solder offers lower melting temperatures and superior wetting properties, making it ideal for high-reliability electronics, while lead-free solder meets RoHS regulations with improved thermal endurance but requires higher reflow temperatures. Understanding your manufacturing processes and environmental standards ensures you select the solder that best balances durability and regulatory compliance.

SnPb vs lead-free solder Infographic

electrown.com

electrown.com