MOSFETs offer high input impedance and low power consumption, making them ideal for digital and analog circuits, while MESFETs excel in high-frequency and microwave applications due to their superior electron mobility and faster switching capabilities. Discover how understanding the distinct advantages of each transistor type can optimize your electronic designs by reading the rest of this article.

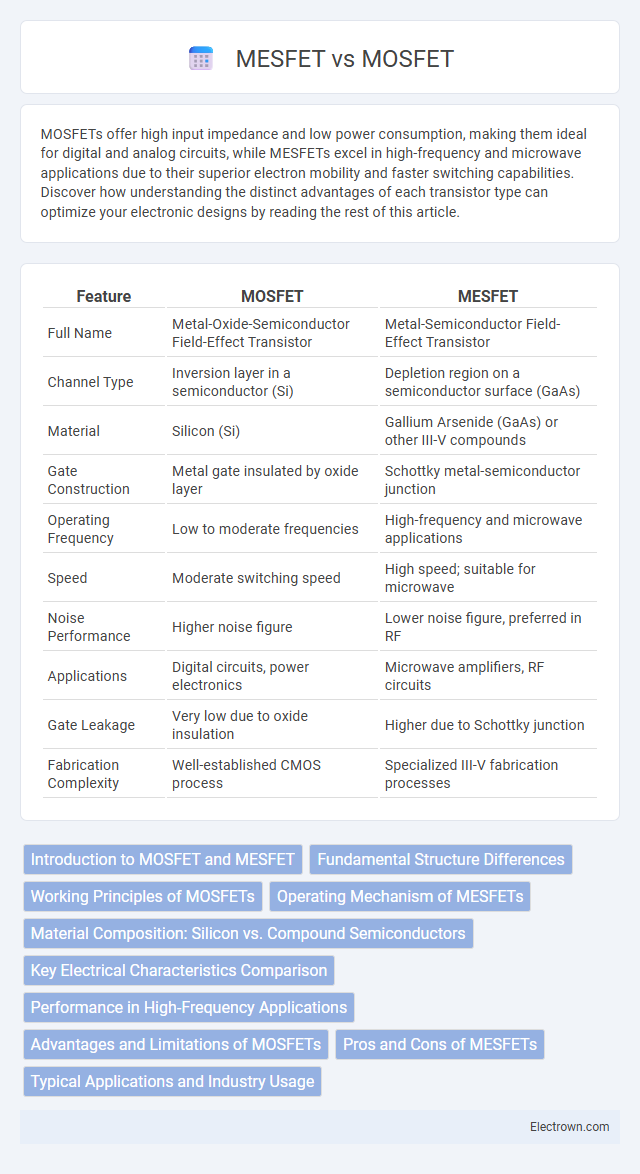

Table of Comparison

| Feature | MOSFET | MESFET |

|---|---|---|

| Full Name | Metal-Oxide-Semiconductor Field-Effect Transistor | Metal-Semiconductor Field-Effect Transistor |

| Channel Type | Inversion layer in a semiconductor (Si) | Depletion region on a semiconductor surface (GaAs) |

| Material | Silicon (Si) | Gallium Arsenide (GaAs) or other III-V compounds |

| Gate Construction | Metal gate insulated by oxide layer | Schottky metal-semiconductor junction |

| Operating Frequency | Low to moderate frequencies | High-frequency and microwave applications |

| Speed | Moderate switching speed | High speed; suitable for microwave |

| Noise Performance | Higher noise figure | Lower noise figure, preferred in RF |

| Applications | Digital circuits, power electronics | Microwave amplifiers, RF circuits |

| Gate Leakage | Very low due to oxide insulation | Higher due to Schottky junction |

| Fabrication Complexity | Well-established CMOS process | Specialized III-V fabrication processes |

Introduction to MOSFET and MESFET

MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) utilizes an oxide layer to control the conductivity of a semiconductor channel, making it ideal for digital circuits and low-power applications. MESFET (Metal-Semiconductor Field-Effect Transistor) employs a Schottky metal-semiconductor junction instead of an oxide layer, providing higher frequency performance suited for microwave and RF technologies. Understanding your specific application helps determine whether MOSFET or MESFET devices offer optimal switching speed, power efficiency, or frequency response.

Fundamental Structure Differences

MOSFETs feature an insulated gate formed by a thin oxide layer separating the gate terminal from the semiconductor channel, enabling voltage-controlled conduction through an inversion layer. MESFETs, in contrast, utilize a Schottky metal-semiconductor junction as the gate, lacking the insulating oxide layer, which allows faster switching but higher gate leakage. The fundamental structural difference lies in the MOSFET's metal-oxide-semiconductor stack versus the MESFET's metal-semiconductor interface, directly impacting their electrical characteristics and applications.

Working Principles of MOSFETs

MOSFETs operate by controlling the voltage applied to the gate terminal, which modulates the conductivity of a semiconductor channel between the source and drain terminals. The gate voltage creates an electric field that induces a conductive channel in the semiconductor, allowing current flow without direct electrical contact. Your device performance benefits from MOSFETs' high input impedance and fast switching speeds, making them ideal for digital and analog circuit applications.

Operating Mechanism of MESFETs

MESFETs operate by controlling the current flow through a Schottky barrier gate, which modulates the channel conductivity in a semiconductor material like GaAs. Unlike MOSFETs that use an oxide-insulator layer for gate control, MESFETs rely on the metal-semiconductor junction to form a depletion region, enabling high-frequency performance. Your choice between MOSFET and MESFET depends on specific application needs, particularly in RF and microwave circuits where MESFETs excel.

Material Composition: Silicon vs. Compound Semiconductors

MOSFETs typically use silicon as their semiconductor material, offering well-established fabrication technology and cost efficiency. MESFETs commonly employ compound semiconductors like gallium arsenide (GaAs), which provide higher electron mobility for faster switching speeds and better high-frequency performance. The difference in material composition directly impacts their electrical characteristics, making MOSFETs suitable for general-purpose applications while MESFETs excel in high-frequency and microwave circuits.

Key Electrical Characteristics Comparison

MOSFETs offer high input impedance and low gate leakage current, making them energy-efficient for digital applications. MESFETs provide higher electron mobility and faster switching speeds, ideal for high-frequency and microwave operations. Your choice depends on the specific electrical performance needed, with MOSFETs excelling in low-power, high-impedance environments and MESFETs suited for high-speed, high-frequency circuits.

Performance in High-Frequency Applications

MESFETs offer superior high-frequency performance compared to MOSFETs due to their lower gate resistance and faster switching speeds, making them ideal for microwave and radio frequency applications. MOSFETs, while widely used in digital circuits, face limitations in high-frequency scenarios because of their gate oxide capacitance, which slows transition times. Consequently, MESFETs dominate in RF amplifiers and oscillators where efficiency and signal integrity are critical at GHz frequencies.

Advantages and Limitations of MOSFETs

MOSFETs offer high input impedance and low power consumption, making them ideal for digital circuits and integrated circuits in microelectronics. Limitations include slower switching speeds and reduced performance at high frequencies compared to MESFETs, which excel in microwave and RF applications due to their high electron mobility. MOSFETs are also more sensitive to radiation and temperature variations, which can affect their reliability in harsh environments.

Pros and Cons of MESFETs

MESFETs offer high electron mobility and fast switching speeds, making them ideal for microwave and high-frequency applications, especially in GaAs technology. They have advantages such as lower noise figures and better thermal stability compared to MOSFETs in certain environments. However, MESFETs suffer from higher fabrication complexity, limited scaling potential, and lower integration density compared to MOSFETs, which can constrain their use in mainstream digital circuits.

Typical Applications and Industry Usage

MOSFETs are widely used in digital circuits, power management, and consumer electronics due to their high input impedance and low power consumption. MESFETs find extensive application in microwave and RF amplifiers, satellite communications, and high-frequency devices because of their superior noise performance and faster switching speeds. The semiconductor industry leverages MOSFET technology for integrated circuits, while MESFETs dominate in aerospace and telecommunications sectors requiring high-frequency operation.

MOSFET vs MESFET Infographic

electrown.com

electrown.com