PECVD and LPCVD are two common chemical vapor deposition techniques used in semiconductor manufacturing, where PECVD operates at lower temperatures using plasma to enhance chemical reactions, resulting in faster deposition and better control over thin-film properties, while LPCVD functions at higher temperatures to produce uniform, high-quality films ideal for complex wafer structures. Explore the rest of the article to understand which method best suits your fabrication needs.

Table of Comparison

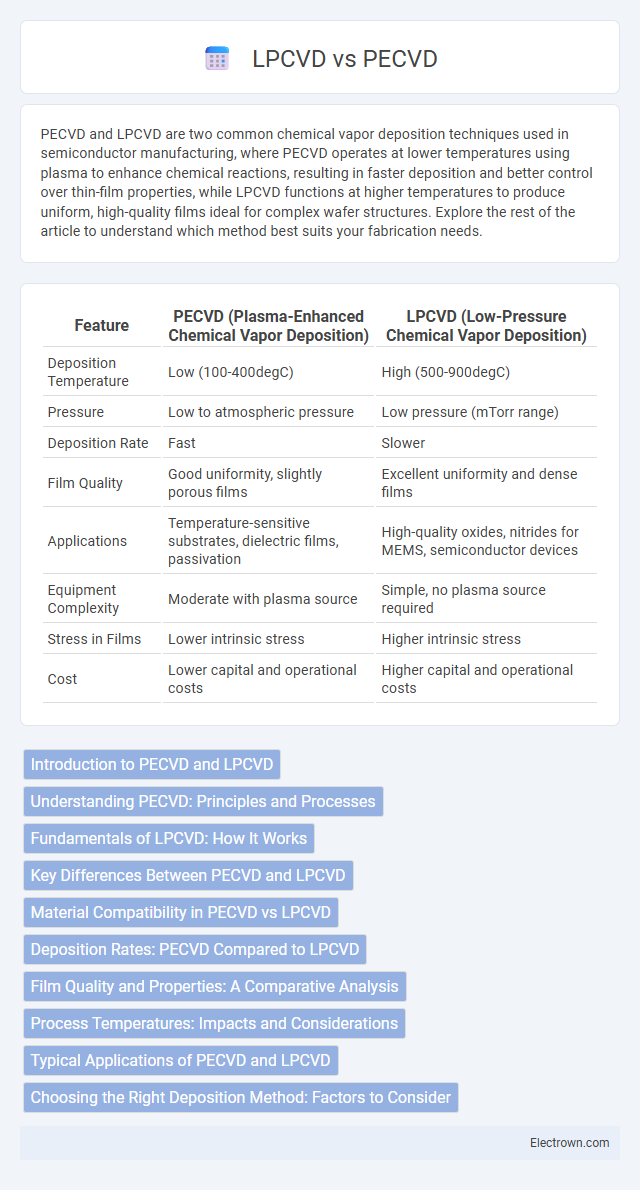

| Feature | PECVD (Plasma-Enhanced Chemical Vapor Deposition) | LPCVD (Low-Pressure Chemical Vapor Deposition) |

|---|---|---|

| Deposition Temperature | Low (100-400degC) | High (500-900degC) |

| Pressure | Low to atmospheric pressure | Low pressure (mTorr range) |

| Deposition Rate | Fast | Slower |

| Film Quality | Good uniformity, slightly porous films | Excellent uniformity and dense films |

| Applications | Temperature-sensitive substrates, dielectric films, passivation | High-quality oxides, nitrides for MEMS, semiconductor devices |

| Equipment Complexity | Moderate with plasma source | Simple, no plasma source required |

| Stress in Films | Lower intrinsic stress | Higher intrinsic stress |

| Cost | Lower capital and operational costs | Higher capital and operational costs |

Introduction to PECVD and LPCVD

Plasma Enhanced Chemical Vapor Deposition (PECVD) and Low-Pressure Chemical Vapor Deposition (LPCVD) are advanced thin film deposition techniques widely used in semiconductor manufacturing. PECVD utilizes plasma to enhance chemical reactions at lower substrate temperatures, enabling deposition on temperature-sensitive materials. LPCVD operates under reduced pressure to achieve uniform, high-quality films with excellent conformality and is ideal for applications requiring high thermal budgets.

Understanding PECVD: Principles and Processes

Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses plasma to enhance chemical reactions, enabling film deposition at lower temperatures than Low-Pressure Chemical Vapor Deposition (LPCVD). This process allows precise control over film properties such as density, stress, and composition, making PECVD ideal for temperature-sensitive substrates and advanced semiconductor manufacturing. Your choice of PECVD ensures efficient deposition of thin films like silicon nitride and silicon dioxide with improved uniformity and reduced thermal budget compared to LPCVD.

Fundamentals of LPCVD: How It Works

LPCVD (Low-Pressure Chemical Vapor Deposition) operates by introducing gaseous precursors into a low-pressure reaction chamber, where elevated temperatures facilitate chemical reactions to deposit uniform thin films on substrates. This technique enables excellent conformality and precise thickness control for materials such as silicon nitride and polysilicon, essential in semiconductor manufacturing and MEMS devices. Your selection of LPCVD ensures superior film quality and step coverage due to the enhanced diffusion and reduced gas-phase reactions at low pressure.

Key Differences Between PECVD and LPCVD

PECVD (Plasma Enhanced Chemical Vapor Deposition) operates at lower temperatures using plasma to enhance chemical reactions, making it ideal for temperature-sensitive substrates. LPCVD (Low Pressure Chemical Vapor Deposition) uses thermal energy at higher temperatures and low pressure to achieve uniform, high-quality films with excellent step coverage. You should consider PECVD for faster deposition and better control over film properties, while LPCVD is preferred for thicker, highly conformal coatings.

Material Compatibility in PECVD vs LPCVD

PECVD offers superior material compatibility due to its low-temperature deposition process, enabling the coating of temperature-sensitive substrates such as polymers and flexible electronics without degradation. LPCVD operates at higher temperatures, typically between 550degC and 850degC, restricting its use to thermally stable materials like silicon, silicon dioxide, and various polysilicon films. The ability of PECVD to maintain substrate integrity while depositing high-quality films makes it ideal for advanced applications requiring delicate material interfaces.

Deposition Rates: PECVD Compared to LPCVD

PECVD offers higher deposition rates compared to LPCVD due to its plasma-enhanced process, which activates chemical reactions at lower temperatures, increasing film growth speed. LPCVD operates at higher temperatures with slower deposition rates but provides better film uniformity and step coverage. Your choice depends on whether faster throughput or superior film quality is the priority.

Film Quality and Properties: A Comparative Analysis

Plasma-Enhanced Chemical Vapor Deposition (PECVD) produces films with lower density but superior conformality and lower deposition temperatures compared to Low-Pressure Chemical Vapor Deposition (LPCVD), making them ideal for sensitive substrates. LPCVD films exhibit higher density, better uniformity, and superior electrical and mechanical properties due to high-temperature processes, which results in reduced hydrogen content and improved crystallinity. The choice between PECVD and LPCVD depends on the desired film attributes, with PECVD favored for stress-sensitive applications and LPCVD preferred when film quality and stability are paramount.

Process Temperatures: Impacts and Considerations

PECVD operates at lower temperatures typically ranging from 200degC to 400degC, making it suitable for temperature-sensitive substrates and reducing thermal stress during deposition. LPCVD requires higher temperatures, often between 600degC and 800degC, which enhances film uniformity and density but limits compatibility with delicate materials. The choice between PECVD and LPCVD largely depends on balancing substrate thermal tolerance with desired film quality and application requirements.

Typical Applications of PECVD and LPCVD

PECVD (Plasma-Enhanced Chemical Vapor Deposition) is typically used for depositing thin films such as silicon nitride, silicon dioxide, and amorphous silicon at low temperatures, making it ideal for temperature-sensitive substrates and applications like passivation layers in solar cells, MEMS devices, and microelectronics. LPCVD (Low Pressure Chemical Vapor Deposition) is preferred for producing high-quality, uniform films such as polysilicon, silicon nitride, and silicon dioxide at higher temperatures, commonly utilized in semiconductor manufacturing for gate oxides, buried layers, and diffusion barrier films. PECVD offers faster deposition rates with good conformity on complex topographies, while LPCVD provides superior film density and electrical properties for critical layers in integrated circuits.

Choosing the Right Deposition Method: Factors to Consider

Selecting between PECVD (Plasma-Enhanced Chemical Vapor Deposition) and LPCVD (Low-Pressure Chemical Vapor Deposition) depends on factors such as desired film quality, substrate temperature sensitivity, and deposition rate. PECVD offers lower temperature processing ideal for temperature-sensitive substrates and provides better step coverage, while LPCVD excels in producing high-quality, uniform films with superior conformality at higher temperatures. Consider the application's thermal budget, film stress tolerance, and throughput requirements to determine the optimal deposition technique.

PECVD vs LPCVD Infographic

electrown.com

electrown.com