Monolithic capacitors offer high reliability and compact size, making them ideal for applications requiring stable capacitance and minimal inductance, while chip capacitors provide versatility and cost-effectiveness for general-purpose use in surface-mount technology. Discover which capacitor type best suits Your electronic projects by exploring the detailed comparisons and specifications in the rest of this article.

Table of Comparison

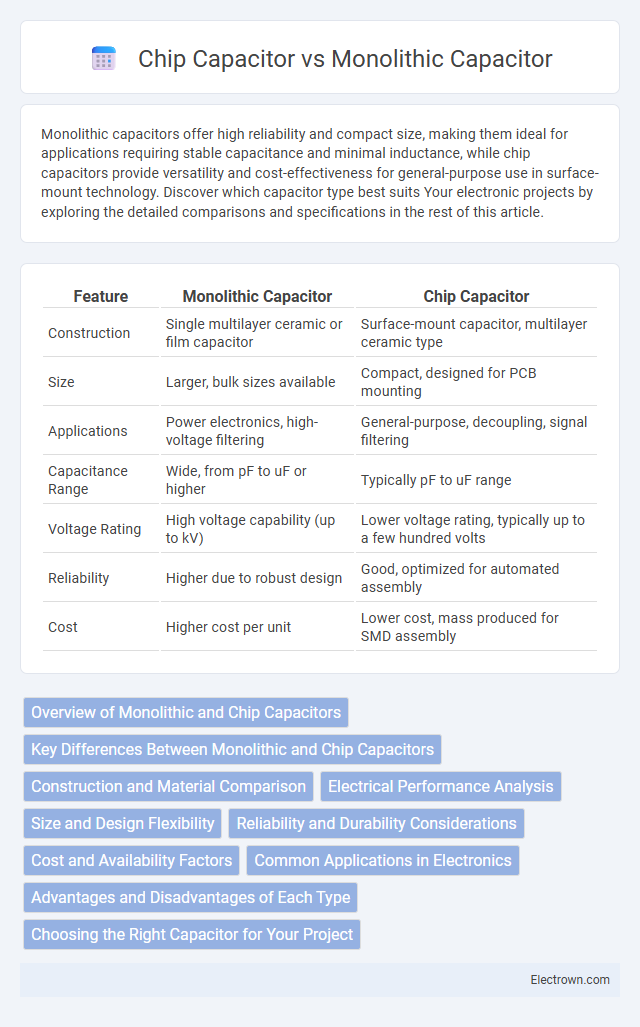

| Feature | Monolithic Capacitor | Chip Capacitor |

|---|---|---|

| Construction | Single multilayer ceramic or film capacitor | Surface-mount capacitor, multilayer ceramic type |

| Size | Larger, bulk sizes available | Compact, designed for PCB mounting |

| Applications | Power electronics, high-voltage filtering | General-purpose, decoupling, signal filtering |

| Capacitance Range | Wide, from pF to uF or higher | Typically pF to uF range |

| Voltage Rating | High voltage capability (up to kV) | Lower voltage rating, typically up to a few hundred volts |

| Reliability | Higher due to robust design | Good, optimized for automated assembly |

| Cost | Higher cost per unit | Lower cost, mass produced for SMD assembly |

Overview of Monolithic and Chip Capacitors

Monolithic capacitors are compact, multilayer ceramic components designed for high capacitance and reliability in electronic circuits, suitable for surface-mount technology. Chip capacitors, typically referring to smaller, discrete capacitors including ceramic or tantalum types, offer versatile performance but usually with lower capacitance compared to monolithic multilayer variants. Your choice depends on circuit requirements like size, capacitance, and mounting method, with monolithic capacitors excelling in integrated, high-density applications.

Key Differences Between Monolithic and Chip Capacitors

Monolithic capacitors are multilayer ceramic capacitors known for high capacitance and stability in compact sizes, while chip capacitors generally refer to surface-mount devices that may include various types like ceramic, tantalum, or film capacitors. The key differences lie in construction and performance: monolithic capacitors use stacked dielectric layers for enhanced reliability and lower equivalent series resistance (ESR), whereas chip capacitors vary widely in materials and characteristics, affecting frequency response and tolerance. Monolithic capacitors excel in high-frequency applications due to their low inductance, unlike some chip capacitors which might prioritize cost or form factor over performance.

Construction and Material Comparison

Monolithic capacitors use multilayer ceramic technology with alternating dielectric and electrode layers, providing high capacitance in a compact form. Chip capacitors, often referring to surface-mount multilayer ceramic capacitors (MLCCs), also utilize ceramic dielectric materials but vary in electrode composition and layer count for cost-effective mass production. The choice of dielectric materials, such as C0G or X7R ceramics, influences temperature stability and capacitance range, distinguishing the performance and application suitability between monolithic and chip capacitors.

Electrical Performance Analysis

Monolithic capacitors offer superior electrical performance with lower equivalent series resistance (ESR) and inductance (ESL), enhancing high-frequency response and reducing signal loss. Chip capacitors provide compact size and high volumetric efficiency but typically exhibit higher ESR and ESL, which can impact performance in high-frequency or high-precision applications. Your choice depends on the specific electrical requirements, such as tolerance, stability, and frequency range, critical for optimal circuit functionality.

Size and Design Flexibility

Monolithic capacitors offer a compact size and uniform structure, enabling high capacitance in a small footprint ideal for space-constrained applications. Chip capacitors provide greater design flexibility with various shapes and sizes, allowing customization for specific circuit board layouts and performance requirements. The choice between the two depends on balancing the need for miniaturization versus adaptable form factors in electronic device design.

Reliability and Durability Considerations

Monolithic capacitors offer superior reliability and durability due to their solid ceramic dielectric and robust construction, making them ideal for high-stress environments with frequent temperature fluctuations. Chip capacitors, while smaller and cost-effective, may be more susceptible to mechanical stress and micro-cracking, which can affect their long-term performance in demanding applications. Choosing the right capacitor ensures your device maintains consistent performance and longevity under varying operational conditions.

Cost and Availability Factors

Monolithic capacitors typically offer lower costs due to mass production and simpler manufacturing processes, making them highly accessible for large-scale applications. Chip capacitors, while slightly more expensive, provide enhanced precision and reliability, which can justify the cost in high-performance electronics. Availability of monolithic capacitors is more widespread across various standard values, whereas chip capacitors may have limited stock depending on specialized specifications.

Common Applications in Electronics

Monolithic capacitors are widely used in power supply filtering, decoupling, and signal coupling due to their high capacitance and reliability in compact circuits. Chip capacitors, favored for their small size and precision, are commonly found in smartphones, laptops, and advanced communication devices to ensure stable signal processing and noise reduction. Your choice depends on the specific electronic application requirements, such as size constraints and performance standards.

Advantages and Disadvantages of Each Type

Monolithic capacitors offer high capacitance values in a compact size and excellent reliability for high-frequency applications, but they can have higher equivalent series resistance (ESR) and voltage limitations compared to chip capacitors. Chip capacitors provide superior frequency response and low ESR, making them ideal for high-precision and high-frequency circuits, though they generally feature lower capacitance and may be more sensitive to mechanical stress. Selecting between monolithic and chip capacitors depends on the specific circuit requirements, including capacitance needs, frequency range, size constraints, and robustness.

Choosing the Right Capacitor for Your Project

Selecting the right capacitor depends on the project's requirements for size, capacitance, and reliability; monolithic capacitors offer higher capacitance values with excellent stability, making them ideal for high-frequency applications. Chip capacitors, typically smaller and surface-mount, provide compactness and ease of automated assembly, suited for space-constrained designs. Evaluating parameters such as voltage rating, dielectric type, and operating environment ensures the optimal balance between performance and durability.

monolithic capacitor vs chip capacitor Infographic

electrown.com

electrown.com