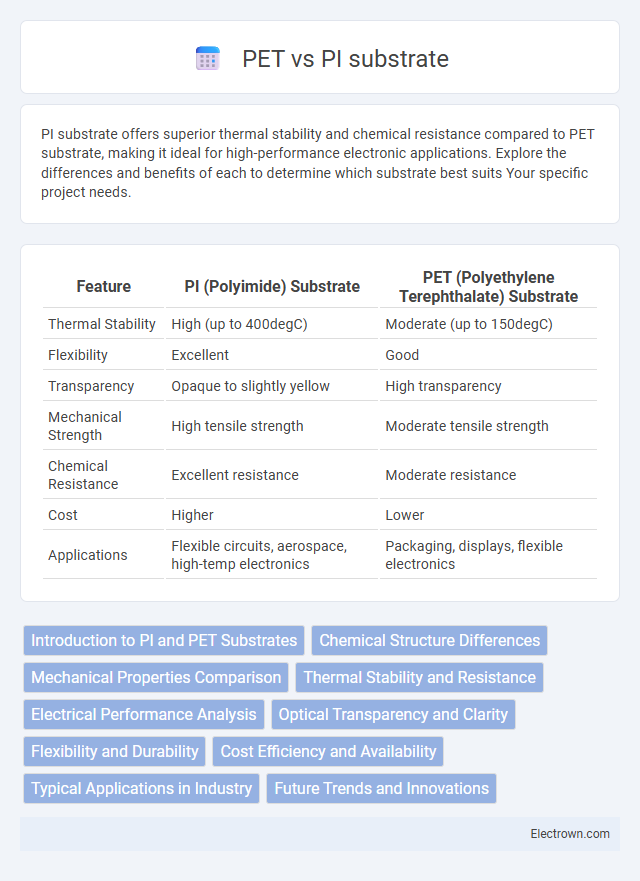

PI substrate offers superior thermal stability and chemical resistance compared to PET substrate, making it ideal for high-performance electronic applications. Explore the differences and benefits of each to determine which substrate best suits Your specific project needs.

Table of Comparison

| Feature | PI (Polyimide) Substrate | PET (Polyethylene Terephthalate) Substrate |

|---|---|---|

| Thermal Stability | High (up to 400degC) | Moderate (up to 150degC) |

| Flexibility | Excellent | Good |

| Transparency | Opaque to slightly yellow | High transparency |

| Mechanical Strength | High tensile strength | Moderate tensile strength |

| Chemical Resistance | Excellent resistance | Moderate resistance |

| Cost | Higher | Lower |

| Applications | Flexible circuits, aerospace, high-temp electronics | Packaging, displays, flexible electronics |

Introduction to PI and PET Substrates

PI (Polyimide) and PET (Polyethylene terephthalate) are widely used substrates in flexible electronics and printed circuit boards, valued for their distinct thermal and mechanical properties. PI substrates exhibit superior thermal stability withstanding temperatures up to 400degC, while PET substrates typically endure up to 150degC, making PI ideal for high-temperature applications. PET substrates offer excellent optical clarity and flexibility, making them preferred in consumer electronics and flexible display applications.

Chemical Structure Differences

Polyimide (PI) substrates exhibit a rigid, aromatic backbone composed of imide groups, contributing to their excellent thermal and chemical stability. In contrast, polyethylene terephthalate (PET) substrates are polyester-based, characterized by repeating ester linkages derived from terephthalic acid and ethylene glycol, resulting in a flexible yet less heat-resistant structure. These fundamental chemical structure differences directly influence the mechanical properties and thermal endurance of PI and PET substrates in electronic and industrial applications.

Mechanical Properties Comparison

PI (Polyimide) substrate exhibits superior mechanical flexibility and high tensile strength, making it ideal for applications requiring durability under bending or twisting. PET (Polyethylene Terephthalate) substrate offers moderate mechanical strength with excellent impact resistance but lower thermal stability compared to PI. The higher Young's modulus and elongation at break values of PI enable better performance in flexible electronics and wearable devices where mechanical resilience is critical.

Thermal Stability and Resistance

Polyimide (PI) substrate exhibits superior thermal stability withstanding continuous use at temperatures up to 400degC, while polyethylene terephthalate (PET) substrates typically endure up to 150degC before deformation risks increase. PI maintains dimensional stability and mechanical integrity under prolonged thermal stress, making it ideal for high-temperature electronic applications. PET substrates offer lower thermal resistance and are more prone to warping and degradation when exposed to elevated temperatures over time.

Electrical Performance Analysis

PI (Polyimide) and PET (Polyethylene Terephthalate) substrates exhibit significant differences in electrical performance, with PI offering superior dielectric strength and thermal stability, making it ideal for high-frequency and high-temperature applications. PET substrates generally have lower dielectric constants and dissipation factors, which can lead to higher signal loss and reduced electrical performance in demanding environments. The choice between PI and PET depends on the specific electrical requirements such as insulation resistance, capacitance, and operating temperature range of the device or circuit.

Optical Transparency and Clarity

PI substrates typically exhibit lower optical transparency and clarity compared to PET substrates due to their inherent amber tint and higher light absorption properties. PET substrates offer superior optical clarity with high transparency levels, making them ideal for applications requiring clear and bright displays. Your choice between PI and PET should consider the importance of visual quality, as PET provides better optical performance for transparent or display-related uses.

Flexibility and Durability

PI (Polyimide) substrate offers exceptional flexibility, making it ideal for applications requiring repeated bending and twisting without degradation, while PET (Polyethylene Terephthalate) substrate provides moderate flexibility but is more prone to cracking under stress. PI substrates boast superior thermal stability and chemical resistance, ensuring long-lasting durability in harsh environments compared to PET substrates. For your projects demanding reliable performance and longevity under dynamic conditions, PI substrate stands out as the more durable and flexible choice.

Cost Efficiency and Availability

Polyimide (PI) substrates generally offer higher cost efficiency compared to poly(ethylene terephthalate) (PET) due to their superior thermal stability and durability, which reduce replacement frequency in high-performance applications. PET substrates are widely available and inexpensive, benefiting mass production where flexibility and lower temperature tolerance suffice. However, for industries requiring enhanced mechanical and chemical resistance, PI substrates provide better long-term value despite their higher initial cost.

Typical Applications in Industry

PI substrates are favored in flexible electronics, aerospace, and medical devices due to their excellent thermal stability and mechanical flexibility. PET substrates commonly serve in packaging, displays, and photovoltaic panels, offering cost-effectiveness and clarity but lower heat resistance. Your choice depends on application demands for durability, temperature tolerance, and flexibility.

Future Trends and Innovations

Future trends in substrate technology emphasize enhanced thermal stability, mechanical flexibility, and environmental sustainability. Innovations in polyimide (PI) focus on reducing moisture absorption and improving dielectric properties, while advancements in polyethylene terephthalate (PET) target increased temperature resistance and recyclability. Emerging hybrid substrates combining PI and PET materials aim to deliver optimized performance for flexible electronics, wearable devices, and next-generation displays.

PI vs PET substrate Infographic

electrown.com

electrown.com