Surface Mount Technology (SMT) offers higher component density and automated assembly capabilities compared to Through-Hole Technology (THT), which provides stronger mechanical bonds suitable for heavier components. Explore the detailed differences and advantages to determine which technology best fits your electronic manufacturing needs.

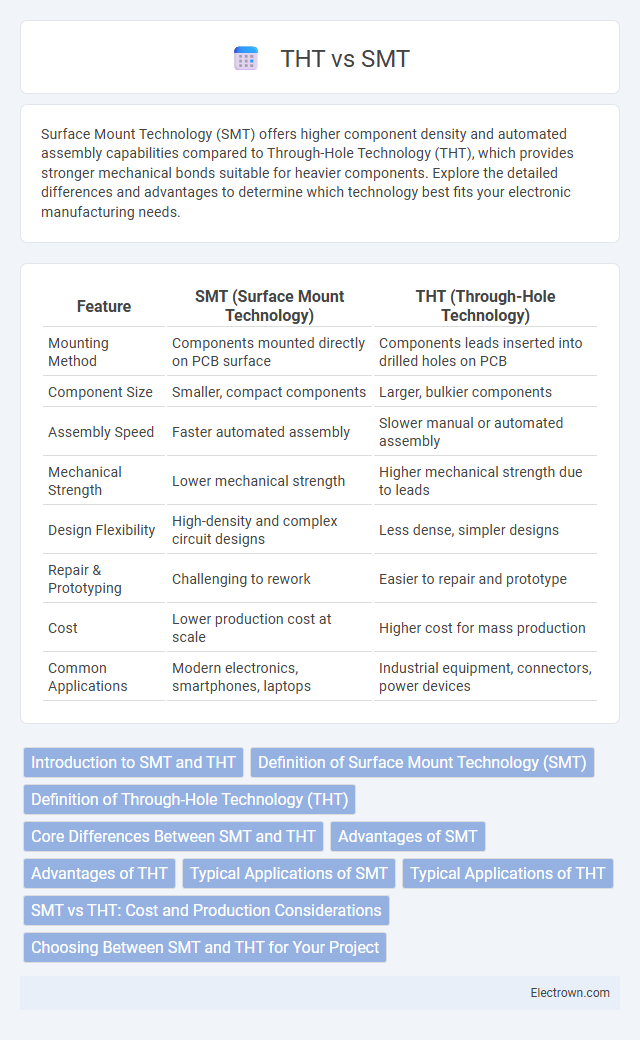

Table of Comparison

| Feature | SMT (Surface Mount Technology) | THT (Through-Hole Technology) |

|---|---|---|

| Mounting Method | Components mounted directly on PCB surface | Components leads inserted into drilled holes on PCB |

| Component Size | Smaller, compact components | Larger, bulkier components |

| Assembly Speed | Faster automated assembly | Slower manual or automated assembly |

| Mechanical Strength | Lower mechanical strength | Higher mechanical strength due to leads |

| Design Flexibility | High-density and complex circuit designs | Less dense, simpler designs |

| Repair & Prototyping | Challenging to rework | Easier to repair and prototype |

| Cost | Lower production cost at scale | Higher cost for mass production |

| Common Applications | Modern electronics, smartphones, laptops | Industrial equipment, connectors, power devices |

Introduction to SMT and THT

Surface Mount Technology (SMT) involves mounting electronic components directly onto the surface of printed circuit boards (PCBs), enabling higher component density and automated assembly processes. Through-Hole Technology (THT) requires inserting component leads into drilled holes on the PCB, providing stronger mechanical bonds ideal for connectors and heavy components. Understanding these differences helps optimize your circuit design for performance and manufacturing efficiency.

Definition of Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is a method for producing electronic circuits in which components are mounted directly onto the surface of printed circuit boards (PCBs) without the need for drilled holes. SMT components are smaller, enabling higher circuit density and improved electrical performance compared to Through-Hole Technology (THT), which uses leads inserted into drilled holes in PCBs. This technology supports automated assembly processes, enhancing manufacturing efficiency and reducing production costs.

Definition of Through-Hole Technology (THT)

Through-Hole Technology (THT) involves mounting electronic components by inserting their leads into pre-drilled holes on a printed circuit board (PCB) and soldering them on the opposite side. This method provides strong mechanical bonds ideal for components requiring durability and high power handling. You'll find THT commonly used in applications where robust connections are prioritized over miniaturization or automated assembly speed.

Core Differences Between SMT and THT

Surface Mount Technology (SMT) uses small, flat components placed directly onto the surface of printed circuit boards (PCBs), enabling higher component density and automated assembly. Through-Hole Technology (THT) involves inserting component leads into drilled holes on the PCB, providing stronger mechanical bonds and better suited for components requiring high durability. SMT supports miniaturization and faster manufacturing, while THT is preferred for high-reliability applications and easier prototyping.

Advantages of SMT

Surface Mount Technology (SMT) offers significant advantages over Through-Hole Technology (THT), including higher component density and reduced manufacturing costs due to automated assembly processes. SMT enables smaller, lighter, and more reliable electronic devices by allowing components to be placed on both sides of the PCB, improving electrical performance and reducing signal path lengths. Your designs can benefit from faster production cycles and increased circuit complexity, making SMT the preferred choice for modern electronics manufacturing.

Advantages of THT

Through-Hole Technology (THT) offers superior mechanical strength and durability compared to Surface Mount Technology (SMT), making it ideal for components subject to mechanical stress or heavy usage. THT components provide easier manual insertion and repairability, which is beneficial for prototyping and small production runs. Your designs benefit from reliable performance in harsh environments where vibration and physical wear are concerns.

Typical Applications of SMT

Surface-mount technology (SMT) is widely used in high-density electronic assemblies such as smartphones, computers, and aerospace equipment due to its ability to place components on both sides of a printed circuit board (PCB) with precision. SMT enables automated production lines, increasing manufacturing speed and reducing labor costs while providing superior electrical performance and reliability compared to through-hole technology (THT). Your devices benefit from SMT's compact, lightweight designs that support complex circuits in consumer electronics and industrial applications.

Typical Applications of THT

Through-Hole Technology (THT) is predominantly used in applications requiring strong mechanical bonds and higher reliability, such as automotive electronics, aerospace systems, and industrial machinery. Its robust construction makes it ideal for components exposed to mechanical stress, high temperatures, and heavy vibrations. THT is also preferred in prototype development and repairable equipment due to ease of manual assembly and testing.

SMT vs THT: Cost and Production Considerations

Surface Mount Technology (SMT) generally offers lower production costs due to its automation-friendly processes and higher component density, resulting in reduced material use and assembly time. Through-Hole Technology (THT), while often more expensive due to manual labor and longer assembly cycles, provides stronger mechanical bonds ideal for heavy or high-stress applications. When evaluating your project, consider SMT for cost-effective mass production and THT when product durability and reliability under physical stress are critical.

Choosing Between SMT and THT for Your Project

Choosing between Surface Mount Technology (SMT) and Through-Hole Technology (THT) depends on your project's requirements for component size, assembly speed, and mechanical strength. SMT offers compact designs and faster automated production, ideal for high-density or complex circuits, while THT provides stronger mechanical connections suitable for components subjected to stress or heavy use. Evaluating factors such as design complexity, volume, and durability helps determine the best technology for your specific application.

SMT vs THT Infographic

electrown.com

electrown.com