A Distributed Bragg Reflector (DBR) consists of multiple alternating layers of materials with different refractive indices designed to reflect specific wavelengths through constructive interference, whereas a Dielectric Mirror is generally made of dielectric materials optimized for high reflectivity over a broad range of wavelengths. Understanding the differences between these mirrors can enhance your knowledge of optical coatings, so continue reading to explore their unique properties and applications.

Table of Comparison

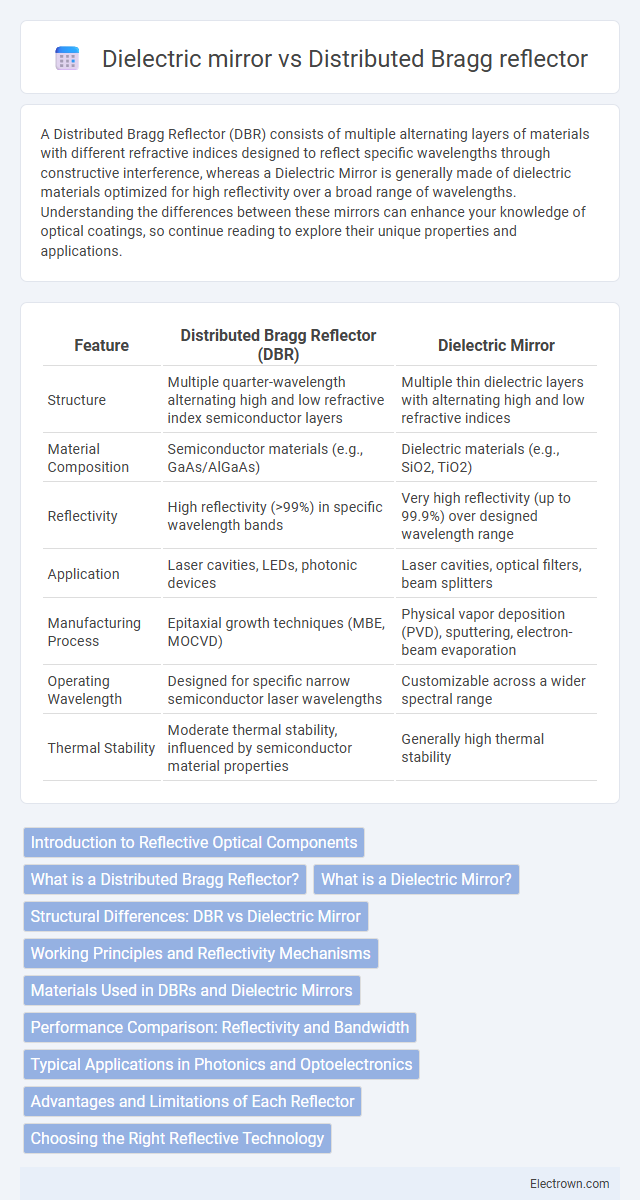

| Feature | Distributed Bragg Reflector (DBR) | Dielectric Mirror |

|---|---|---|

| Structure | Multiple quarter-wavelength alternating high and low refractive index semiconductor layers | Multiple thin dielectric layers with alternating high and low refractive indices |

| Material Composition | Semiconductor materials (e.g., GaAs/AlGaAs) | Dielectric materials (e.g., SiO2, TiO2) |

| Reflectivity | High reflectivity (>99%) in specific wavelength bands | Very high reflectivity (up to 99.9%) over designed wavelength range |

| Application | Laser cavities, LEDs, photonic devices | Laser cavities, optical filters, beam splitters |

| Manufacturing Process | Epitaxial growth techniques (MBE, MOCVD) | Physical vapor deposition (PVD), sputtering, electron-beam evaporation |

| Operating Wavelength | Designed for specific narrow semiconductor laser wavelengths | Customizable across a wider spectral range |

| Thermal Stability | Moderate thermal stability, influenced by semiconductor material properties | Generally high thermal stability |

Introduction to Reflective Optical Components

Distributed Bragg reflectors (DBRs) and dielectric mirrors are essential reflective optical components used in photonics to achieve high reflectivity by means of periodic variations in refractive index. Both DBRs and dielectric mirrors rely on multiple alternating layers of materials with different refractive indices, creating constructive interference for specific wavelength ranges, but DBRs are often engineered for semiconductor applications with precise layer thickness control. These components play a critical role in laser cavities, optical filters, and sensors where controlling reflectance and wavelength selectivity is paramount.

What is a Distributed Bragg Reflector?

A Distributed Bragg Reflector (DBR) is a highly reflective optical structure composed of alternating layers of materials with different refractive indices, designed to reflect specific wavelength ranges through constructive interference. The periodic variation in refractive index creates a photonic bandgap that prevents light propagation within certain wavelengths, enhancing reflectivity. DBRs are commonly used in lasers, optical filters, and semiconductor devices to achieve precise wavelength control and high reflectivity efficiency.

What is a Dielectric Mirror?

A Dielectric Mirror consists of multiple thin layers of dielectric materials with alternating high and low refractive indices, engineered to reflect specific wavelengths of light efficiently. It operates through constructive interference, where light waves are reflected at each layer interface, producing high reflectivity within a targeted spectral range. You can use Dielectric Mirrors in laser cavities, optical instruments, and telecommunications for precise wavelength control and minimal energy loss.

Structural Differences: DBR vs Dielectric Mirror

Distributed Bragg reflectors (DBRs) consist of multiple alternating layers of materials with varying refractive indices, precisely engineered to create constructive interference at specific wavelengths. Dielectric mirrors are a type of DBR, composed exclusively of dielectric (non-metallic) materials, designed for high reflectivity and low absorption across targeted spectral bands. The key structural difference lies in the controlled layer thickness and refractive index contrast in DBRs tailored for specific optical properties, while dielectric mirrors emphasize material purity and layer uniformity to optimize reflectance and durability.

Working Principles and Reflectivity Mechanisms

Distributed Bragg reflectors (DBRs) consist of multiple alternating layers of materials with contrasting refractive indices, creating constructive interference at specific wavelengths through periodic quarter-wavelength thicknesses. Dielectric mirrors operate on the same principle but are optimized with dielectric materials for higher reflectivity and lower absorption, enabling near-total reflection in targeted spectral ranges. The reflectivity mechanism in both relies on the precise control of optical path differences, producing high reflectance through coherent multiple internal reflections and phase matching.

Materials Used in DBRs and Dielectric Mirrors

Distributed Bragg Reflectors (DBRs) are composed of alternating layers of semiconductor materials with different refractive indices, such as gallium arsenide (GaAs) and aluminum arsenide (AlAs), optimized for specific wavelength reflection and high reflectivity in optoelectronic devices. Dielectric mirrors typically use alternating layers of dielectric materials like silicon dioxide (SiO2) and titanium dioxide (TiO2) or zirconium dioxide (ZrO2), offering excellent reflectivity and durability across a broad spectrum of wavelengths. Your choice between DBRs and dielectric mirrors depends on factors such as operational wavelength, thermal stability, and integration requirements within optical systems.

Performance Comparison: Reflectivity and Bandwidth

Distributed Bragg reflectors (DBRs) achieve high reflectivity by stacking alternating layers of materials with different refractive indices, often exceeding 99% reflectance in specific wavelength bands. Dielectric mirrors share a similar multilayer structure but can be optimized for broader bandwidths by varying layer thickness and refractive index contrast, providing more flexibility in design. Your choice depends on whether you prioritize maximum reflectivity within a narrow band (DBRs) or a trade-off with broader bandwidth performance (dielectric mirrors).

Typical Applications in Photonics and Optoelectronics

Distributed Bragg reflectors (DBRs) are widely used in vertical-cavity surface-emitting lasers (VCSELs), wavelength filters, and optical sensors due to their high reflectivity and wavelength selectivity. Dielectric mirrors find applications in laser cavities, interferometers, and high-power laser systems where broadband reflectivity and high damage thresholds are crucial. Both components optimize light confinement and control in photonics and optoelectronics, enhancing device performance in communication and sensing technologies.

Advantages and Limitations of Each Reflector

Distributed Bragg reflectors (DBRs) offer high reflectivity with precise wavelength selectivity, making them ideal for laser cavities and optical filters but exhibit sensitivity to angle and polarization, which can limit performance in broader applications. Dielectric mirrors provide broadband reflectance with high damage thresholds and excellent durability, suited for high-power laser systems, though their fabrication complexity and potential for limited spectral tuning pose constraints. Both types balance reflectivity, bandwidth, and application-specific requirements, influencing their choice based on optical design priorities and operational environments.

Choosing the Right Reflective Technology

Distributed Bragg reflectors (DBRs) utilize alternating layers of dielectric materials with differing refractive indices to achieve high reflectivity through constructive interference, making them ideal for applications requiring precise wavelength selectivity and high reflectivity in narrow spectral bands. Dielectric mirrors, on the other hand, often refer broadly to mirrors composed of multiple thin-film dielectric layers designed for broad reflectance and durability across wider wavelength ranges. Selecting the right reflective technology depends on factors such as operating wavelength, bandwidth, angle of incidence, and environmental stability, where DBRs excel in laser cavities and optical filters, while dielectric mirrors suit broadband applications and general-purpose optics.

Distributed Bragg reflector vs Dielectric mirror Infographic

electrown.com

electrown.com