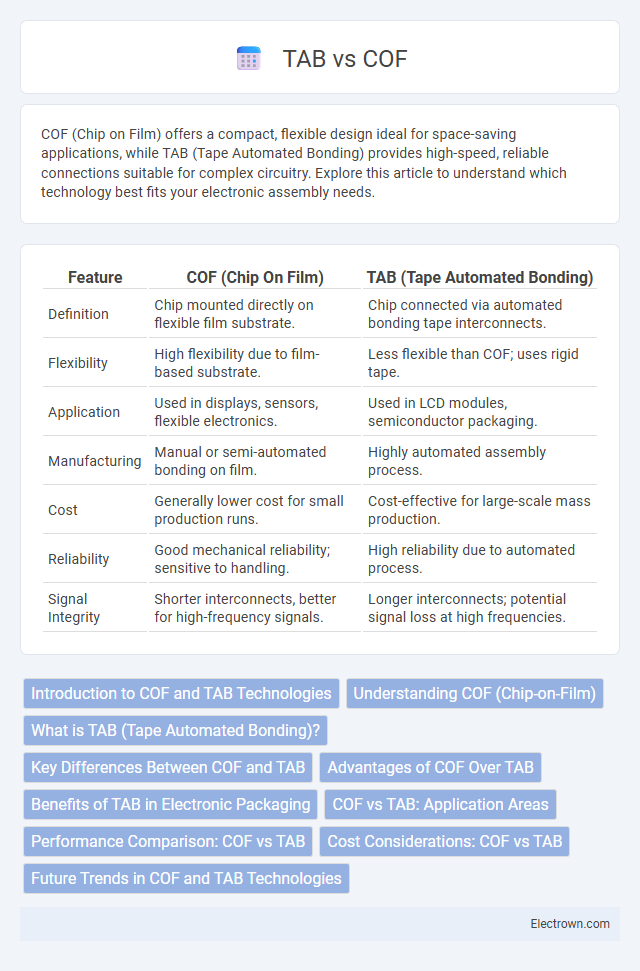

COF (Chip on Film) offers a compact, flexible design ideal for space-saving applications, while TAB (Tape Automated Bonding) provides high-speed, reliable connections suitable for complex circuitry. Explore this article to understand which technology best fits your electronic assembly needs.

Table of Comparison

| Feature | COF (Chip On Film) | TAB (Tape Automated Bonding) |

|---|---|---|

| Definition | Chip mounted directly on flexible film substrate. | Chip connected via automated bonding tape interconnects. |

| Flexibility | High flexibility due to film-based substrate. | Less flexible than COF; uses rigid tape. |

| Application | Used in displays, sensors, flexible electronics. | Used in LCD modules, semiconductor packaging. |

| Manufacturing | Manual or semi-automated bonding on film. | Highly automated assembly process. |

| Cost | Generally lower cost for small production runs. | Cost-effective for large-scale mass production. |

| Reliability | Good mechanical reliability; sensitive to handling. | High reliability due to automated process. |

| Signal Integrity | Shorter interconnects, better for high-frequency signals. | Longer interconnects; potential signal loss at high frequencies. |

Introduction to COF and TAB Technologies

COF (Chip-On-Film) technology involves directly mounting semiconductor chips onto a flexible film substrate, optimizing space and enhancing electrical performance in display panels. TAB (Tape Automated Bonding) features semiconductor chips bonded to a metalized tape carrier with fine-pitch interconnects, enabling precise connections in compact electronic assemblies. Both COF and TAB are essential for high-resolution displays and miniaturized electronic devices, offering distinct advantages in flexibility, manufacturing efficiency, and signal integrity.

Understanding COF (Chip-on-Film)

COF (Chip-on-Film) technology involves directly mounting semiconductor chips onto a flexible polyimide film, enabling compact and lightweight electronic assemblies primarily used in display panels and wearable devices. This method enhances signal integrity and reduces parasitic inductance compared to traditional TAB (Tape Automated Bonding), which bonds chips to a flexible tape with metallic circuits before attaching to the substrate. COF's precise alignment and reliable electrical connections contribute to higher performance in flexible electronics, making it a preferred choice over TAB in modern flat-panel displays.

What is TAB (Tape Automated Bonding)?

Tape Automated Bonding (TAB) is a semiconductor packaging technology that involves attaching a silicon chip to a flexible polyimide tape with fine copper leads, enabling precise and compact electrical connections. This method allows high-density interconnections while maintaining minimal package size and excellent electrical performance. TAB is commonly used in applications requiring enhanced thermal management and mechanical flexibility compared to traditional Chip-On-Film (COF) techniques.

Key Differences Between COF and TAB

COF (Chip on Film) connects a semiconductor chip directly to a flexible film, offering compactness and flexibility ideal for lightweight electronics, while TAB (Tape Automated Bonding) uses a flat metal lead frame to bond chips with higher mechanical strength and precise alignment. COF is preferred for applications requiring thin, bendable circuits like flexible displays, whereas TAB suits high-reliability devices in harsh environments due to its robust packaging. Your choice depends on factors like device flexibility, reliability demands, and production cost efficiency.

Advantages of COF Over TAB

COF (Chip on Film) technology offers superior flexibility and thinner profile compared to TAB (Tape Automated Bonding), making it ideal for compact electronic devices like flexible displays and wearable gadgets. Its enhanced reliability comes from fewer interconnects and improved resistance to vibration and mechanical stress, reducing failure rates in high-performance applications. COF also enables higher-density routing and better thermal management, supporting advanced miniaturization and improved device longevity.

Benefits of TAB in Electronic Packaging

Tape Automated Bonding (TAB) enhances electronic packaging by enabling precise, high-density interconnections with excellent electrical performance and thermal management. Compared to Chip-On-Film (COF), TAB offers improved mechanical reliability due to its robust polyimide tape substrate, which withstands thermal cycling and mechanical stress better. The process also allows for thinner packages and reduced material usage, contributing to miniaturization and cost-effectiveness in advanced electronics manufacturing.

COF vs TAB: Application Areas

COF (Chip on Film) technology is widely used in flexible display applications such as OLED screens, smartphones, and tablets due to its thin, light, and flexible characteristics. TAB (Tape Automated Bonding) is commonly applied in semiconductor packaging and LCD panels, particularly where precise, high-density connections are required. Your choice between COF and TAB should consider the specific application area, with COF favored for flexible electronics and TAB preferred for rigid, high-performance circuit integration.

Performance Comparison: COF vs TAB

Chip-on-Film (COF) technology delivers superior electrical performance with reduced parasitic capacitance and inductance compared to Tape-Automated Bonding (TAB), enabling higher speed and better signal integrity in flexible display applications. COF also offers enhanced mechanical reliability due to its thin and flexible interposer design, which reduces stress on solder joints relative to TAB's stiff tape substrate. Overall, COF outperforms TAB in minimizing signal loss and supporting higher resolution displays with improved manufacturing yield.

Cost Considerations: COF vs TAB

Cost considerations between Chip on Film (COF) and Tape Automated Bonding (TAB) focus on materials, process complexity, and scalability. COF generally incurs lower costs due to simpler equipment requirements and reduced material waste, making it ideal for high-volume production. TAB, while offering superior electrical performance and mechanical reliability, often involves higher initial investment and operational expenses due to precision alignment and bonding equipment.

Future Trends in COF and TAB Technologies

COF (Chip on Film) and TAB (Tape Automated Bonding) technologies are evolving with a strong emphasis on miniaturization, flexibility, and enhanced electrical performance to meet the demands of next-generation electronics. Innovations in COF are driving improvements in flexible display integration and higher-density interconnections, while TAB advancements focus on superior thermal management and finer pitch bonding to boost device reliability. Your choice between COF and TAB will depend on the specific application requirements for future-proof, high-performance electronic assemblies.

COF vs TAB Infographic

electrown.com

electrown.com