Fused silica offers superior thermal stability and higher purity compared to quartz, making it ideal for high-precision optical and semiconductor applications. Discover how these differences affect your choice by reading the rest of the article.

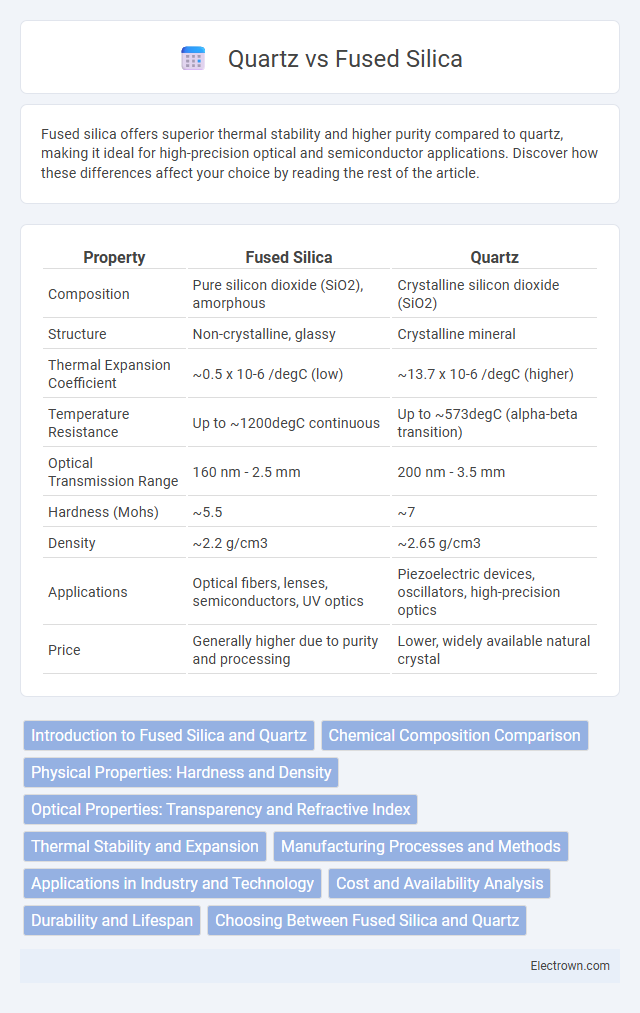

Table of Comparison

| Property | Fused Silica | Quartz |

|---|---|---|

| Composition | Pure silicon dioxide (SiO2), amorphous | Crystalline silicon dioxide (SiO2) |

| Structure | Non-crystalline, glassy | Crystalline mineral |

| Thermal Expansion Coefficient | ~0.5 x 10-6 /degC (low) | ~13.7 x 10-6 /degC (higher) |

| Temperature Resistance | Up to ~1200degC continuous | Up to ~573degC (alpha-beta transition) |

| Optical Transmission Range | 160 nm - 2.5 mm | 200 nm - 3.5 mm |

| Hardness (Mohs) | ~5.5 | ~7 |

| Density | ~2.2 g/cm3 | ~2.65 g/cm3 |

| Applications | Optical fibers, lenses, semiconductors, UV optics | Piezoelectric devices, oscillators, high-precision optics |

| Price | Generally higher due to purity and processing | Lower, widely available natural crystal |

Introduction to Fused Silica and Quartz

Fused silica and quartz are both forms of silicon dioxide (SiO2) but differ significantly in structure and purity. Fused silica is a synthetic, non-crystalline material with high thermal stability and low thermal expansion, making it ideal for precision optical components and semiconductor manufacturing. Quartz, a naturally occurring crystalline form, is widely used in electronics, timekeeping, and optical applications due to its piezoelectric properties and durability.

Chemical Composition Comparison

Fused silica is made from pure silicon dioxide (SiO2) in an amorphous, non-crystalline form, whereas quartz is a crystalline form of silicon dioxide with a well-ordered lattice structure. The lack of impurities and inclusions in fused silica results in higher purity and greater chemical stability compared to natural quartz. Your choice between fused silica and quartz will impact performance in applications requiring precise optical clarity and chemical resistance.

Physical Properties: Hardness and Density

Fused silica exhibits a hardness of approximately 6.5 on the Mohs scale, slightly lower than quartz, which rates around 7. Both materials have closely related densities, with fused silica averaging 2.20 g/cm3 and quartz about 2.65 g/cm3, reflecting differences in their atomic structures. Understanding these variations helps you select the optimal material for applications requiring specific mechanical and physical properties.

Optical Properties: Transparency and Refractive Index

Fused silica offers superior optical transparency across a broad wavelength range, including ultraviolet, visible, and infrared light, with minimal absorption and scattering. Its refractive index is approximately 1.46, providing excellent clarity and low dispersion, which is crucial for high-precision optical applications. Quartz, while also highly transparent, has a slightly higher refractive index around 1.54 and exhibits birefringence, which can affect the polarization of light in your optical system.

Thermal Stability and Expansion

Fused silica exhibits superior thermal stability with a low coefficient of thermal expansion around 0.5 x 10^-6 /degC, making it highly resistant to thermal shock compared to quartz, which expands at approximately 13 x 10^-6 /degC. Quartz's crystalline structure causes anisotropic expansion, leading to potential cracking or deformation under rapid temperature changes, whereas fused silica's amorphous form maintains dimensional stability. Your choice of material should consider fused silica for applications requiring minimal thermal distortion and enhanced durability under extreme temperature variations.

Manufacturing Processes and Methods

Fused silica is produced by melting high-purity silicon dioxide at extremely high temperatures using flame fusion or electric arc melting, resulting in a non-crystalline, amorphous glass with superior thermal shock resistance. Quartz is typically obtained through natural mining followed by precision cutting and polishing, retaining its crystalline structure that offers excellent optical and electrical properties. Your choice between fused silica and quartz depends on whether you require the uniformity and thermal stability of fused silica or the natural crystallinity and piezoelectric characteristics of quartz.

Applications in Industry and Technology

Fused silica and quartz have distinct roles in industry and technology due to their unique properties; fused silica is preferred for high-performance optical components, semiconductor fabrication, and precision instrumentation because of its superior thermal stability and low thermal expansion. Quartz is widely used in electronics, especially in oscillators and resonators, as well as in glass manufacturing and timekeeping devices due to its piezoelectric properties. Your choice between fused silica and quartz depends on the specific application requirements such as thermal resistance, optical clarity, or electrical behavior.

Cost and Availability Analysis

Fused silica generally incurs higher production costs due to its superior purity and controlled manufacturing processes compared to quartz, which is more abundant and naturally occurring. Quartz is widely available in nature, making it a more cost-effective option for large-scale applications, while fused silica commands a premium price driven by its enhanced thermal and optical properties. Industrial demand and geographic accessibility also influence market price fluctuations, with fused silica often favored in high-precision industries despite its elevated cost.

Durability and Lifespan

Fused silica exhibits superior durability and a longer lifespan compared to quartz due to its highly pure amorphous structure, which enhances resistance to thermal shock and chemical corrosion. Quartz, being crystalline, is more prone to micro-cracks and degradation under extreme temperature variations, reducing its operational lifespan in high-stress environments. The stability and robustness of fused silica make it the preferred material in precision optical and semiconductor applications requiring prolonged durability.

Choosing Between Fused Silica and Quartz

Choosing between fused silica and quartz hinges on application requirements such as thermal stability, purity, and optical properties. Fused silica, synthesized through melting high-purity silica, offers superior thermal shock resistance and ultraviolet transparency, making it ideal for high-precision optical components and semiconductor manufacturing. Quartz, a naturally occurring crystalline form, provides robust mechanical strength and is preferred in applications requiring piezoelectric properties or cost-effective bulk materials.

Fused silica vs Quartz Infographic

electrown.com

electrown.com