Dual in-line packages (DIP) feature two parallel rows of pins, making them ideal for through-hole mounting and easy prototyping, while Quad flat packages (QFP) have leads on all four sides, optimizing space for surface-mount applications in compact devices. Explore the article to understand how these packaging types impact your electronic design and component selection.

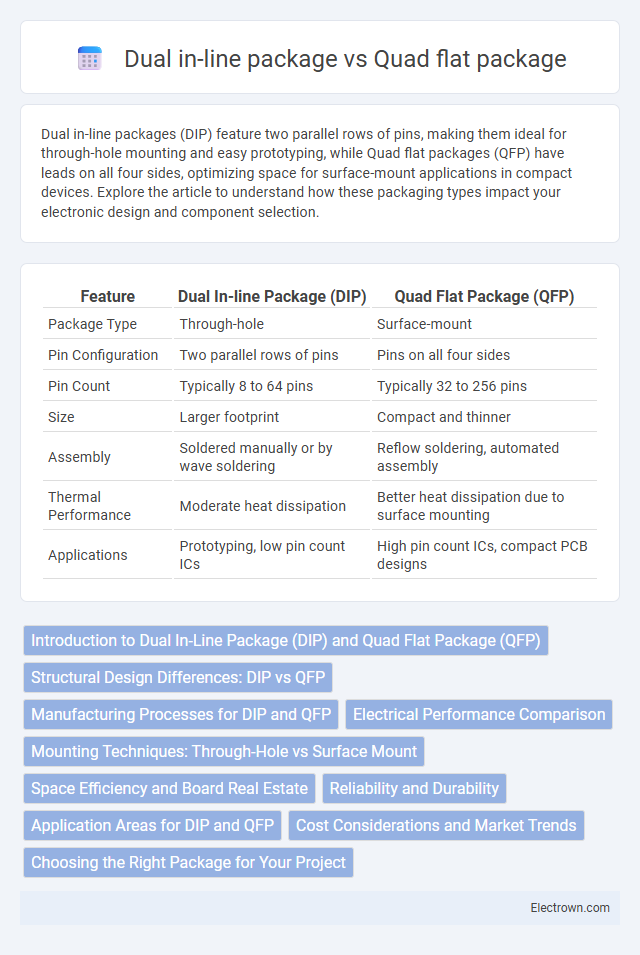

Table of Comparison

| Feature | Dual In-line Package (DIP) | Quad Flat Package (QFP) |

|---|---|---|

| Package Type | Through-hole | Surface-mount |

| Pin Configuration | Two parallel rows of pins | Pins on all four sides |

| Pin Count | Typically 8 to 64 pins | Typically 32 to 256 pins |

| Size | Larger footprint | Compact and thinner |

| Assembly | Soldered manually or by wave soldering | Reflow soldering, automated assembly |

| Thermal Performance | Moderate heat dissipation | Better heat dissipation due to surface mounting |

| Applications | Prototyping, low pin count ICs | High pin count ICs, compact PCB designs |

Introduction to Dual In-Line Package (DIP) and Quad Flat Package (QFP)

Dual In-Line Package (DIP) features two parallel rows of through-hole pins designed for easy insertion into printed circuit boards, commonly used in prototyping and through-hole applications. Quad Flat Package (QFP) offers numerous leads on all four sides in a flat, surface-mount design, enabling higher pin density and smaller footprint suitable for modern compact electronics. Understanding these package types helps you select the appropriate integrated circuit format based on assembly method and space constraints.

Structural Design Differences: DIP vs QFP

Dual in-line package (DIP) features two parallel rows of through-hole pins extending perpendicularly from a rectangular housing, optimized for easy insertion into PCB sockets or soldering directly onto boards. Quad flat package (QFP) exhibits a flat, square or rectangular body with gull-wing leads extending outward on all four sides, designed for surface mounting on PCB pads, enabling higher pin density and reduced footprint. Your choice between DIP and QFP impacts assembly methods, thermal performance, and compactness in electronic circuit design.

Manufacturing Processes for DIP and QFP

Dual in-line packages (DIP) are manufactured using through-hole technology where leads are inserted into drilled holes on the PCB and soldered, enabling robust mechanical strength and easier manual assembly. Quad flat packages (QFP) utilize surface-mount technology with fine-pitched leads extending from all four sides, requiring precise placement and reflow soldering for automated, high-density PCB designs. Your choice between DIP and QFP impacts manufacturing efficiency, assembly complexity, and suitability for automated versus manual processes.

Electrical Performance Comparison

Dual in-line packages (DIP) typically offer lower parasitic capacitance and inductance due to their through-hole design, resulting in improved signal integrity for low-frequency applications. Quad flat packages (QFP) benefit from shorter lead lengths and higher pin counts, enhancing high-frequency performance and enabling better thermal dissipation. Your choice between DIP and QFP should consider the operating frequency and power requirements to optimize electrical performance.

Mounting Techniques: Through-Hole vs Surface Mount

Dual In-line Package (DIP) components utilize through-hole mounting techniques, where leads pass through drilled holes on the PCB and are soldered on the opposite side, providing robust mechanical stability and ease of manual assembly. Quad Flat Package (QFP) components employ surface mount technology (SMT), soldering leads directly onto pads on the PCB surface, which allows for higher component density and is better suited for automated assembly processes. Through-hole mounting in DIP is generally preferred for prototyping and low-frequency applications, while SMT in QFP is dominant in high-speed, compact, and mass-produced electronic devices.

Space Efficiency and Board Real Estate

Dual in-line packages (DIP) typically consume more board space due to their through-hole mounting and larger pin spacing, whereas Quad flat packages (QFP) offer superior space efficiency with their surface-mount technology and closely packed pins. QFP designs minimize board real estate usage, allowing higher component density and improved performance in compact devices. Your choice between DIP and QFP influences overall PCB layout, especially when optimizing for limited space and high integration.

Reliability and Durability

Dual in-line packages (DIPs) offer enhanced mechanical stability due to their through-hole mounting, making them more reliable in environments with mechanical stress and vibration. Quad Flat Packages (QFPs), while providing higher pin density and compact size, rely on surface-mount technology, which can be more susceptible to solder joint fatigue and thermal cycling stress, potentially reducing durability in harsh conditions. The robust construction of DIPs generally results in longer lifecycle performance in applications demanding high reliability under mechanical strain.

Application Areas for DIP and QFP

Dual in-line package (DIP) components are commonly used in prototyping, educational kits, and through-hole circuit boards where easy manual insertion and soldering are required. Quad flat package (QFP) devices find extensive application in high-performance electronics such as microcontrollers, digital signal processors, and complex integrated circuits due to their compact surface-mount design and high pin count. Your choice between DIP and QFP should consider the application's space constraints, assembly method, and complexity of the electronic device.

Cost Considerations and Market Trends

Dual in-line packages (DIPs) generally offer lower manufacturing costs due to simpler design and easier manual assembly, making them suitable for low-volume or prototyping applications. Quad flat packages (QFPs), favored in mass production and high-performance electronics, incur higher costs driven by advanced packaging technology and automated assembly processes. Current market trends show increasing adoption of QFPs in consumer electronics, driven by demand for compact, high-pin-count devices, while DIPs remain relevant in educational kits and niche markets.

Choosing the Right Package for Your Project

Selecting the right package between Dual In-line Package (DIP) and Quad Flat Package (QFP) depends on factors such as board space, component density, and assembly method. DIP offers ease of prototyping and through-hole mounting suitable for lower-density projects, while QFP provides higher pin count and surface-mount technology ideal for compact, high-performance designs. Evaluating project requirements like size constraints, thermal management, and manufacturing capabilities ensures optimal package choice for reliability and efficiency.

Dual in-line package vs Quad flat package Infographic

electrown.com

electrown.com