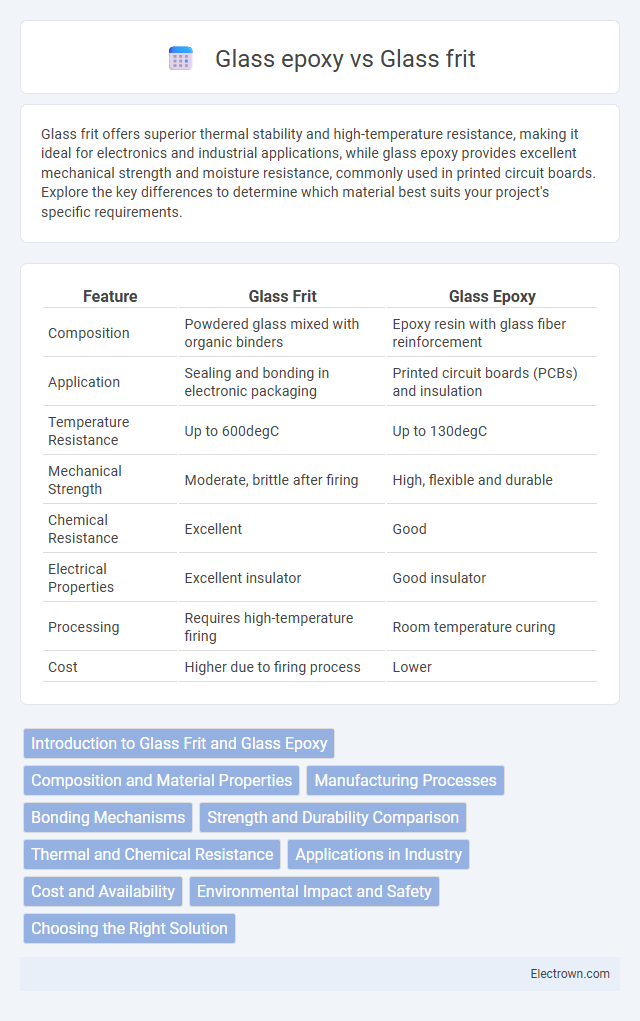

Glass frit offers superior thermal stability and high-temperature resistance, making it ideal for electronics and industrial applications, while glass epoxy provides excellent mechanical strength and moisture resistance, commonly used in printed circuit boards. Explore the key differences to determine which material best suits your project's specific requirements.

Table of Comparison

| Feature | Glass Frit | Glass Epoxy |

|---|---|---|

| Composition | Powdered glass mixed with organic binders | Epoxy resin with glass fiber reinforcement |

| Application | Sealing and bonding in electronic packaging | Printed circuit boards (PCBs) and insulation |

| Temperature Resistance | Up to 600degC | Up to 130degC |

| Mechanical Strength | Moderate, brittle after firing | High, flexible and durable |

| Chemical Resistance | Excellent | Good |

| Electrical Properties | Excellent insulator | Good insulator |

| Processing | Requires high-temperature firing | Room temperature curing |

| Cost | Higher due to firing process | Lower |

Introduction to Glass Frit and Glass Epoxy

Glass frit consists of finely ground glass particles fused at high temperatures, commonly used in electronics and ceramics for sealing and insulating purposes. Glass epoxy is a composite material made by embedding woven glass fibers in an epoxy resin matrix, offering high strength and excellent electrical insulation in PCB manufacturing. Both materials serve critical roles in electronic packaging and circuit board integrity, each optimized for specific thermal and mechanical performance requirements.

Composition and Material Properties

Glass frit consists of finely ground glass powder fused at high temperatures, forming a rigid, inorganic material with excellent thermal stability and chemical resistance. Glass epoxy, composed of woven glass fibers embedded in an epoxy resin matrix, offers superior mechanical strength, electrical insulation, and flexibility. The inorganic nature of glass frit provides high durability and heat resistance, whereas glass epoxy combines structural reinforcement with lightweight and excellent dielectric properties.

Manufacturing Processes

Glass frit involves the manufacturing process of melting raw materials to form a powdered glass used in sealing applications through sintering, providing excellent thermal and mechanical stability. Glass epoxy composites are produced by impregnating glass fibers with epoxy resin and curing them to create lightweight, durable materials ideal for circuit boards and structural components. Your choice between glass frit and glass epoxy depends on manufacturing requirements such as thermal resistance and mechanical strength.

Bonding Mechanisms

Glass frit bonding relies on a sintering process where finely ground glass particles melt and fuse with the substrate, creating a strong mechanical and chemical bond through viscous flow and diffusion. Glass epoxy bonding involves an adhesive matrix combining epoxy resin and glass fibers, which cures to form a durable, flexible bond via polymerization and interfacial adhesion. The key difference is glass frit offers high-temperature stability and hermetic sealing, while glass epoxy provides enhanced toughness and resistance to mechanical stress.

Strength and Durability Comparison

Glass frit offers superior strength and durability compared to glass epoxy due to its inorganic composition and high-temperature firing process, which results in enhanced thermal stability and resistance to mechanical stress. Glass epoxy, while easier to process and more flexible, tends to degrade faster under prolonged exposure to heat and chemicals, making it less reliable for high-stress applications. Your choice depends on the specific performance requirements, with glass frit favored for extreme durability and glass epoxy suited for cost-effective, moderate-strength uses.

Thermal and Chemical Resistance

Glass frit offers superior thermal resistance, enduring temperatures up to 1100degC, making it ideal for high-temperature applications such as electronics and ceramics. In contrast, glass epoxy composites typically tolerate lower temperatures around 130-180degC but exhibit excellent chemical resistance to solvents and acids, preferred in printed circuit boards. The choice between glass frit and glass epoxy depends on the specific thermal and chemical resistance requirements of the intended application.

Applications in Industry

Glass frit is widely used in the electronics industry for sealing and encapsulating components due to its excellent thermal stability and chemical resistance, making it ideal for applications such as solar panels and hermetic packaging. Glass epoxy, commonly utilized in printed circuit boards (PCBs), offers robust mechanical strength and electrical insulation properties, essential for aerospace and telecommunications equipment. Choosing between glass frit and glass epoxy depends on your industry's specific requirements for thermal durability and mechanical performance.

Cost and Availability

Glass frit generally offers a lower cost compared to glass epoxy due to its simpler manufacturing process and wide availability as a raw material in ceramics and electronics industries. Glass epoxy, commonly used in high-performance printed circuit boards, tends to be more expensive because of its complex resin matrices and specialized production techniques. Availability of glass frit is more widespread globally, whereas glass epoxy may face supply constraints depending on resin quality and regional production capacity.

Environmental Impact and Safety

Glass frit offers a lower environmental impact due to its inorganic composition, which reduces the release of harmful volatile organic compounds (VOCs) compared to glass epoxy. Glass epoxy contains organic resins that can emit hazardous fumes during manufacturing and disposal, posing health risks to workers and environmental concerns. Choosing glass frit can enhance your safety protocols by minimizing toxic exposure and supporting eco-friendly manufacturing processes.

Choosing the Right Solution

Glass frit offers superior thermal stability and high-temperature resistance, making it ideal for applications requiring durable, heat-resistant bonding, such as in electronics packaging and solar panels. Glass epoxy combines excellent mechanical strength with electrical insulation properties, suited for printed circuit boards and lightweight structural components. Selecting the right solution depends on the operating environment and performance requirements, focusing on thermal tolerance for glass frit and electrical insulation for glass epoxy.

Glass frit vs Glass epoxy Infographic

electrown.com

electrown.com